Stoffregen Motorsports

Explorer

I've been building this Jeepster for a while now, but decided it was time to share it with y'all.

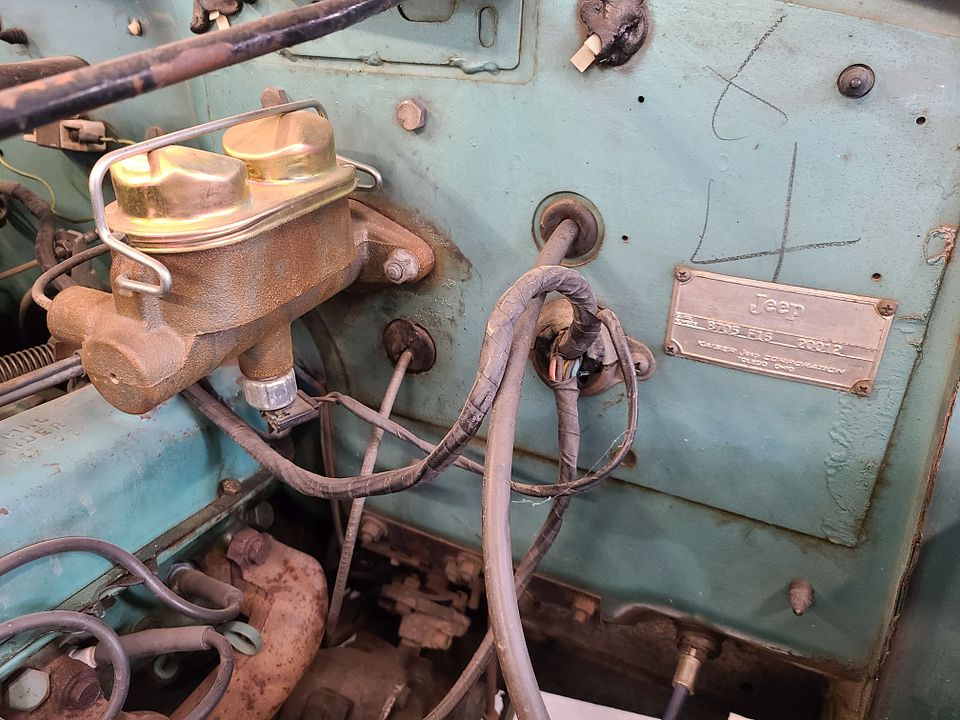

This Jeepster began life with a Jeep family. The original owner had a Jeep dealership in Kentucky, but had this Jeep at his second home in the Colorado Rockies. I picked it up from a collector in Sacramento who had about one hundred cars and trucks in his eclectic collection. There were so many cars that caught my attention, it was hard to focus on the Jeep. The shining star of his collection was a very early Austin Healey 100/4 Le Mans spec car that was originally owned and raced by Augie Pabst. There was also a Porsche 944 that he offered to me for $800, but it was so full of rat turds that I almost threw up.

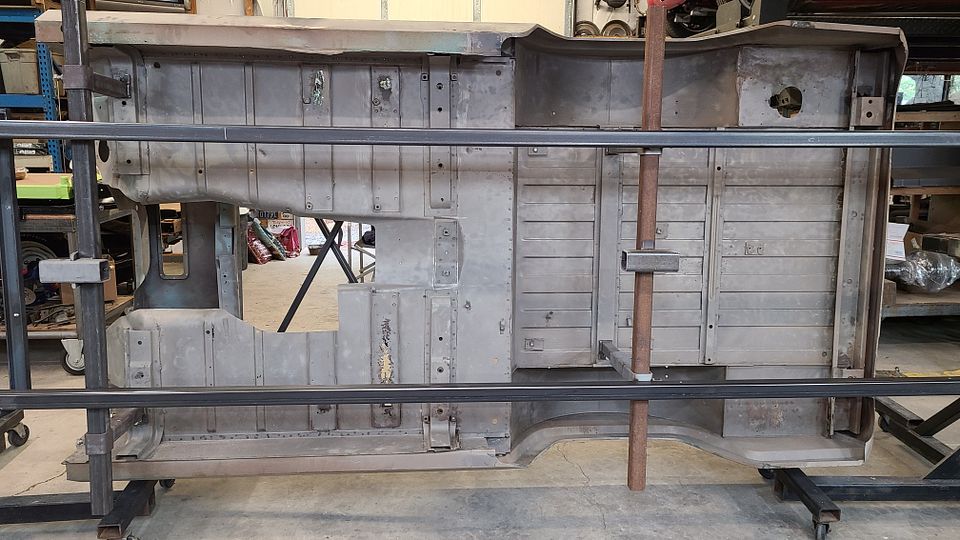

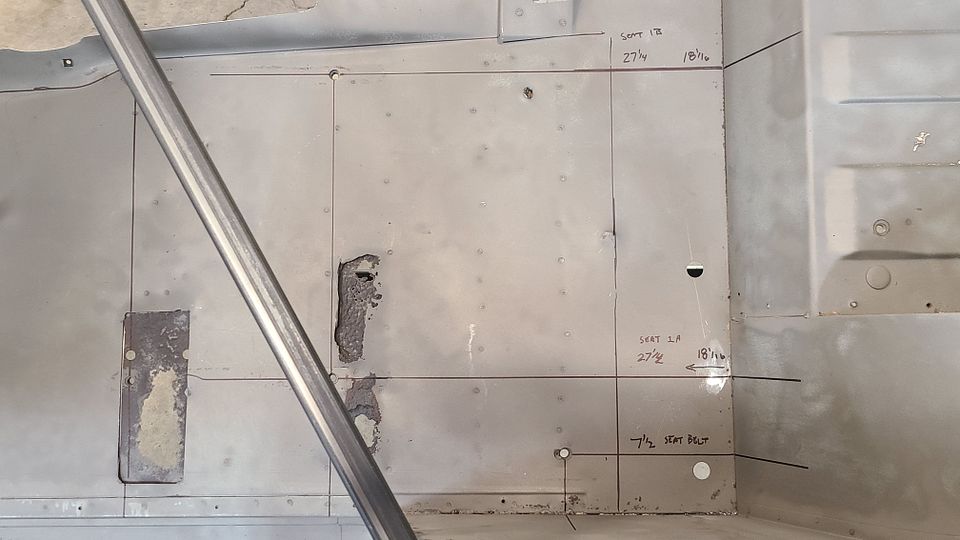

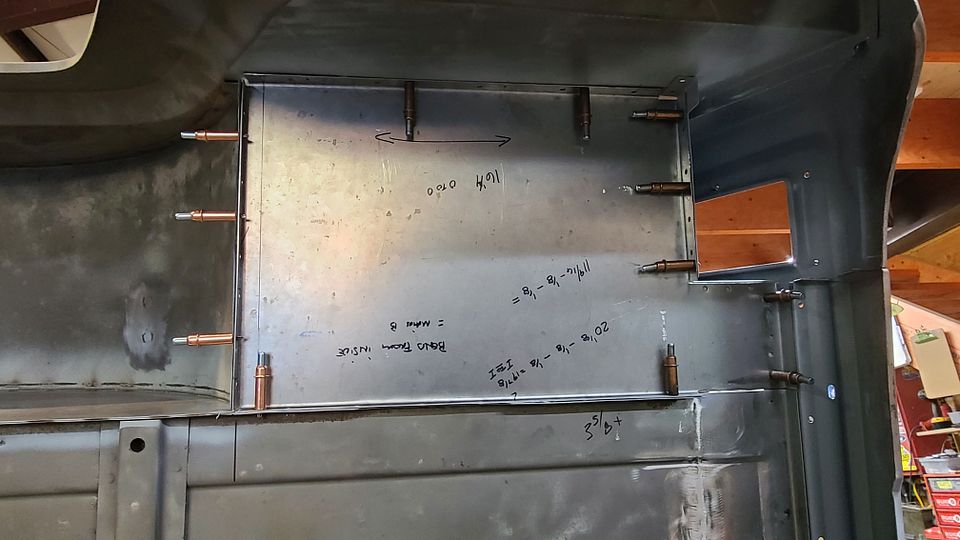

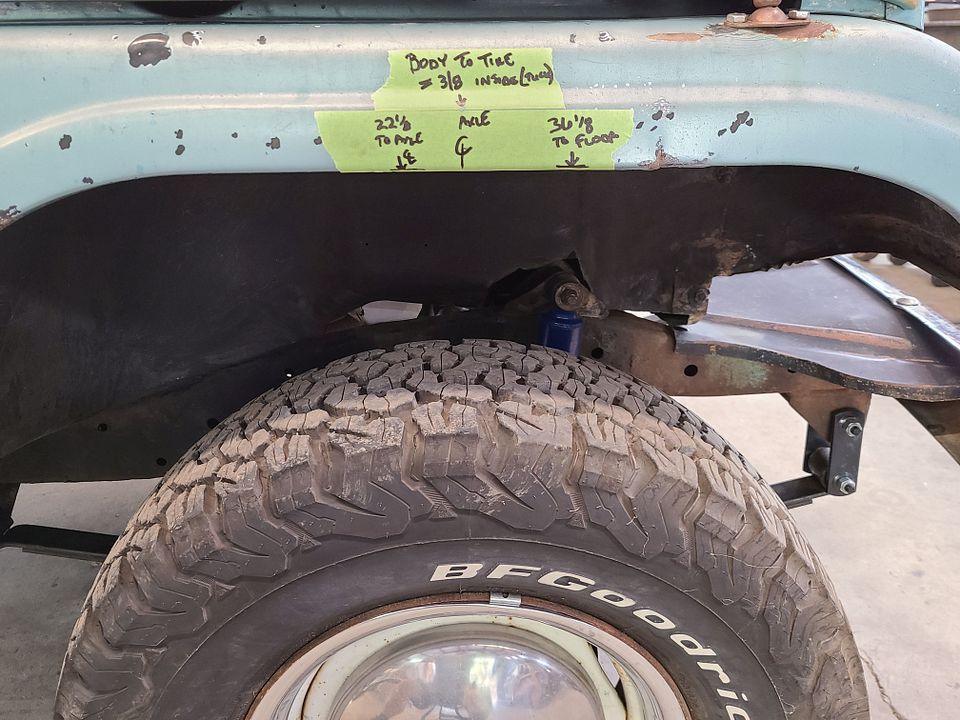

The Jeepster was very clean and original, but had a few rust spots that would need attention. It ran and drove nicely, and was a perfect candidate for a resto-mod build. A price was settled upon and the Jeep was delivered to my shop the next day.

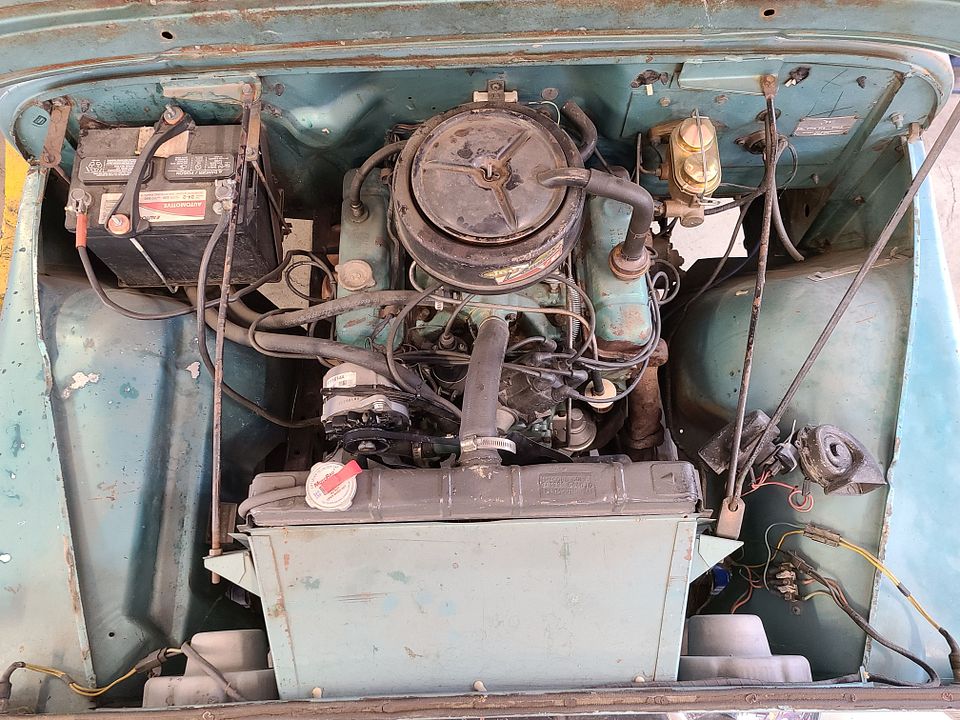

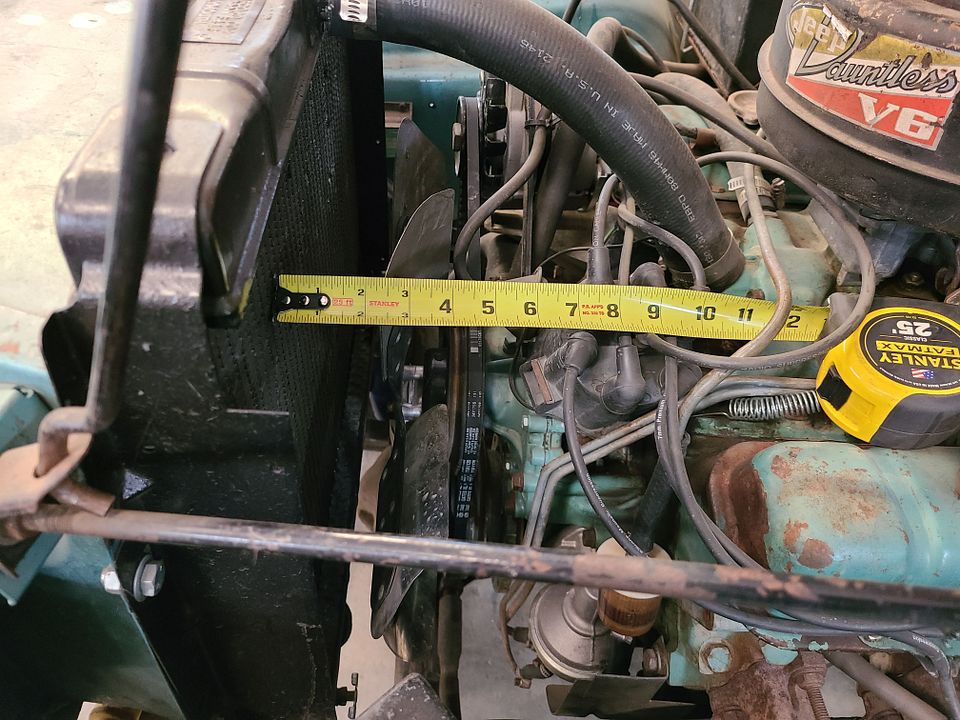

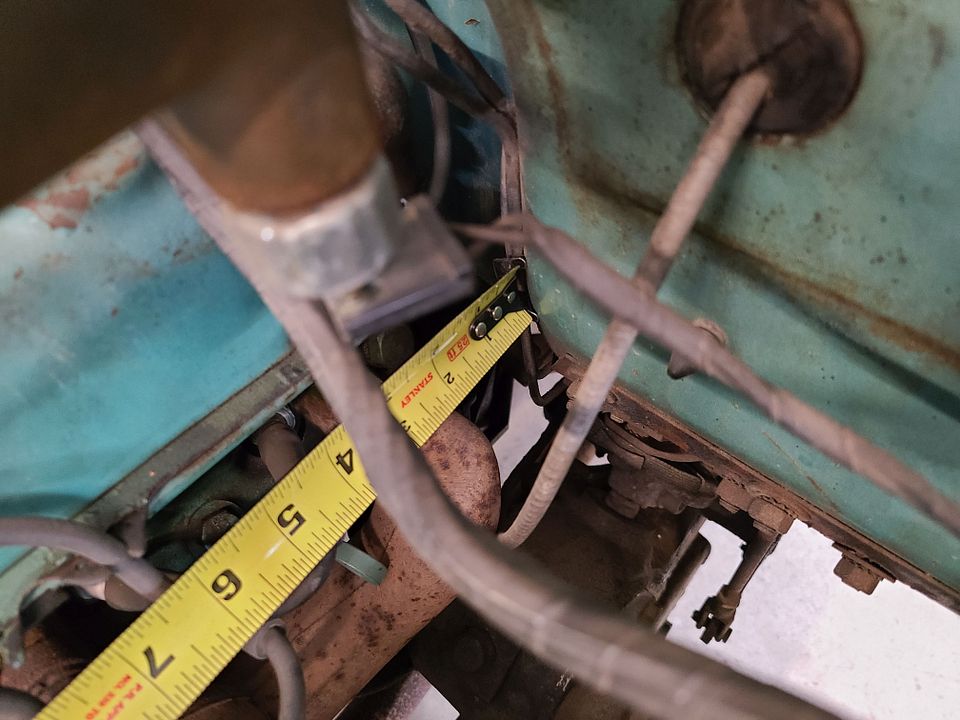

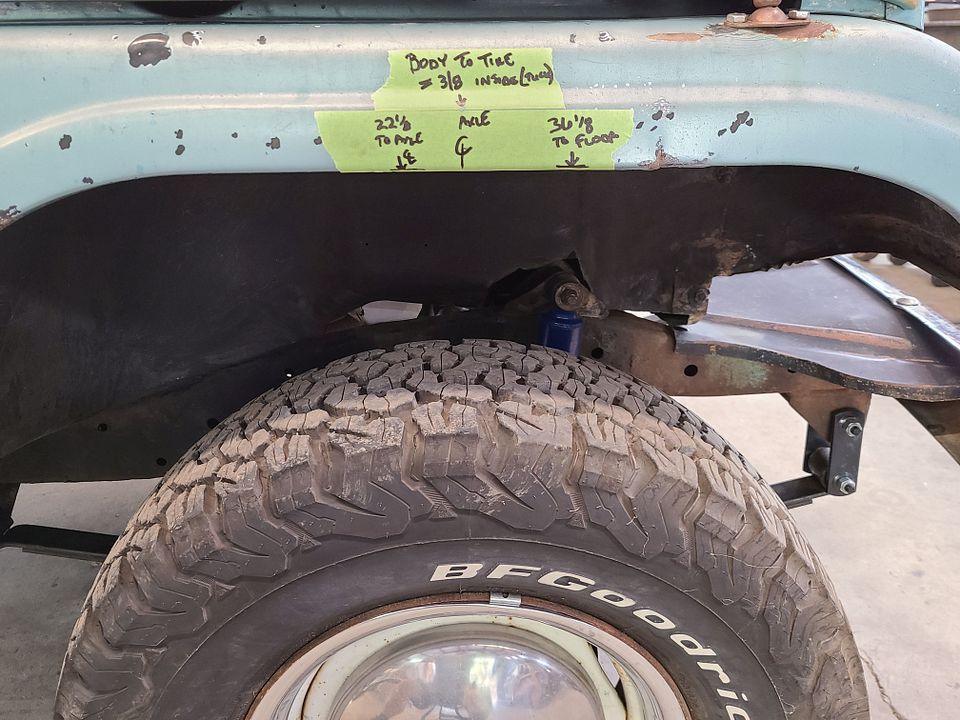

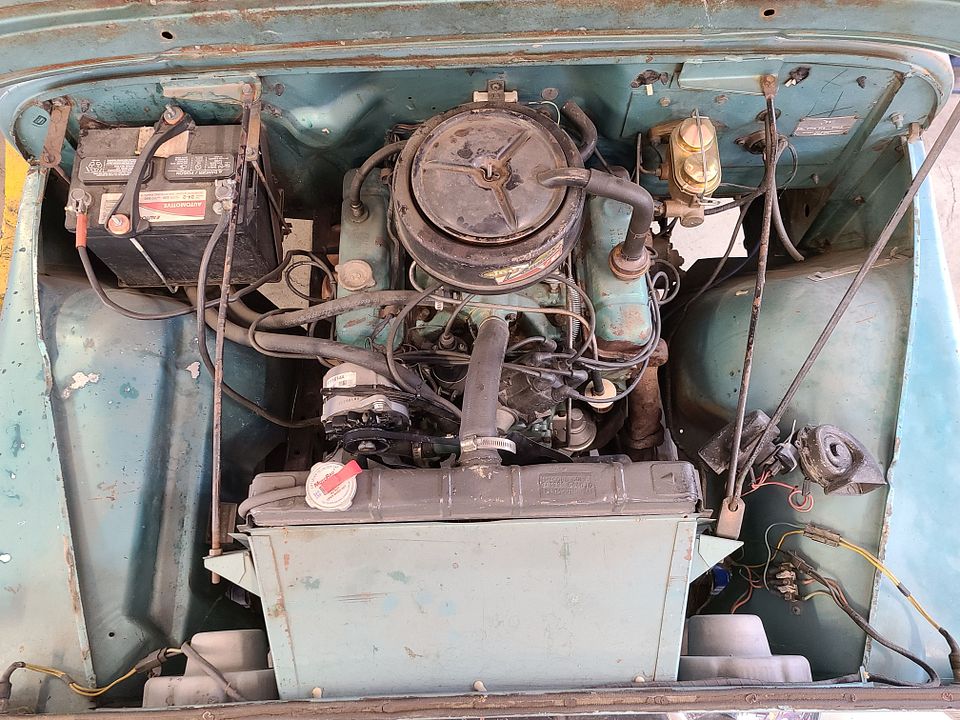

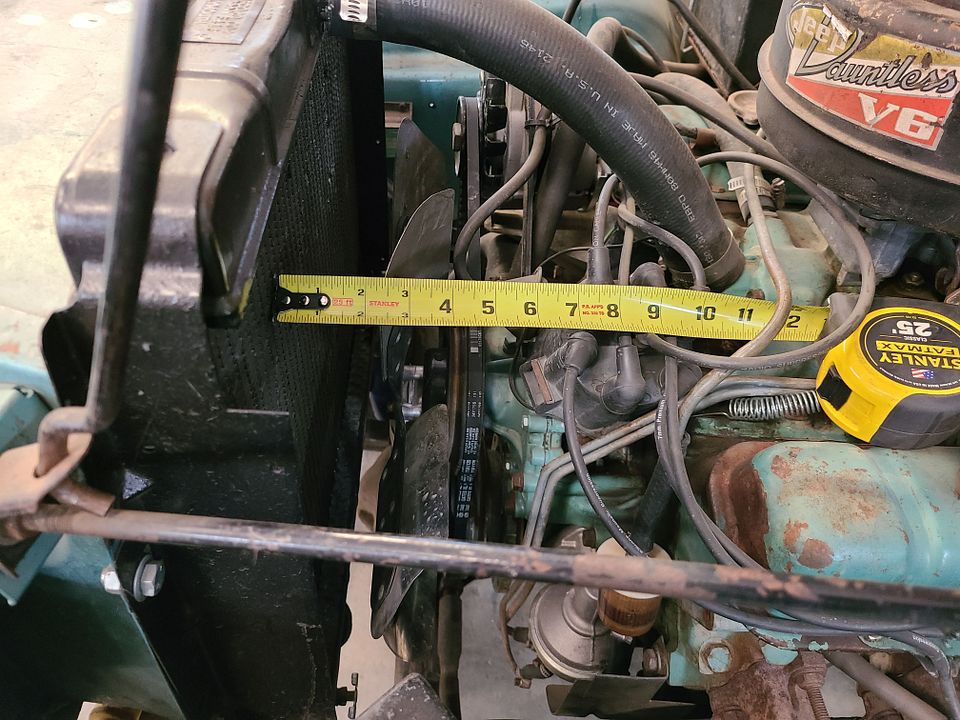

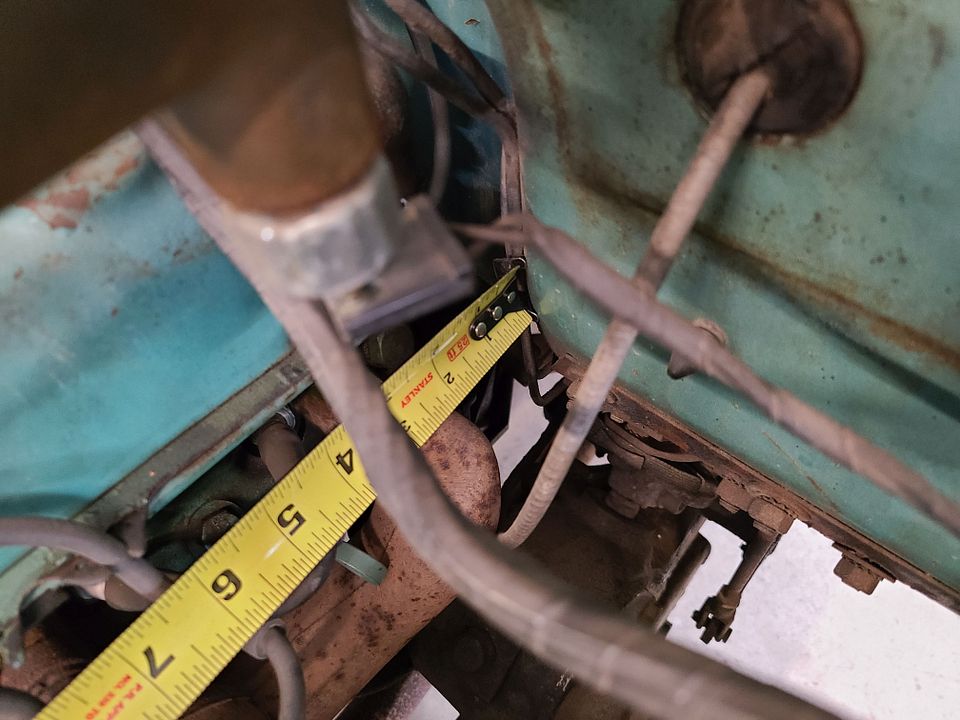

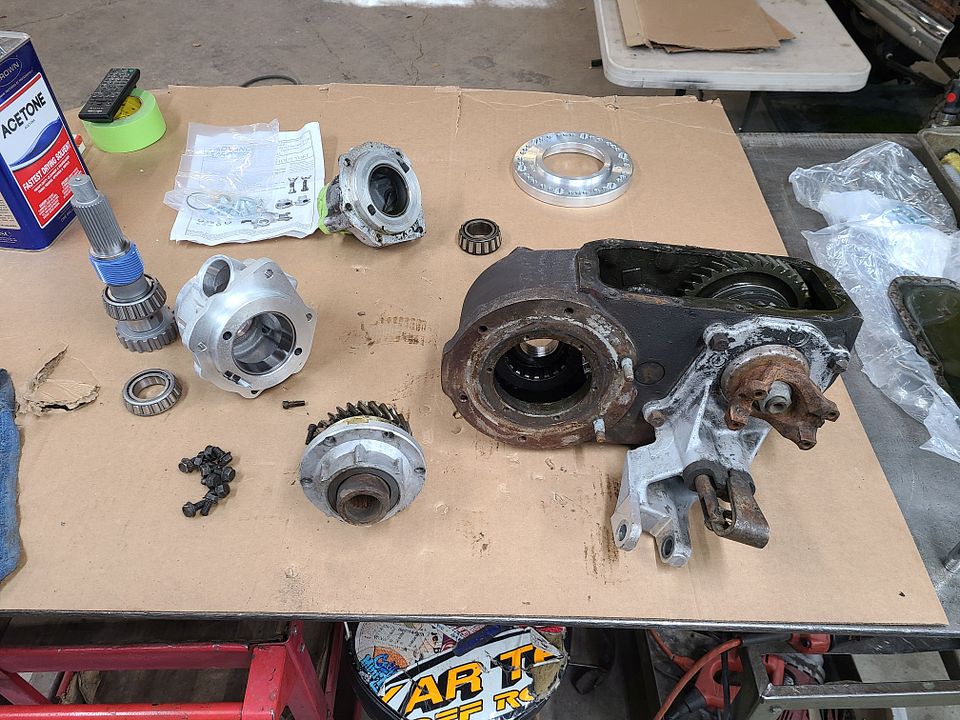

Not really knowing what direction to take the build, we knew that we wanted to keep the basic appearance, but completely restore it and repower it. The original Dauntless V6 was yanked and put on the shelf, and the body was removed for a mock up of the new drivetrain. Ultimately we settled upon a basic LS3 crate motor, which came from Maita Chevrolet in Sac, with the intention of back-dating the look of the engine to the look of a 1960's truck engine, you know, orange, steel valve covers, carburetor intake, etc. For the transmission, it had to have a manual, so a new Tremec TR4050 was ordered from Matthew Jackson at Advance Adapters. After a basic mock up, I knew it was going to be a tight fit.

Let's get started with some pics.

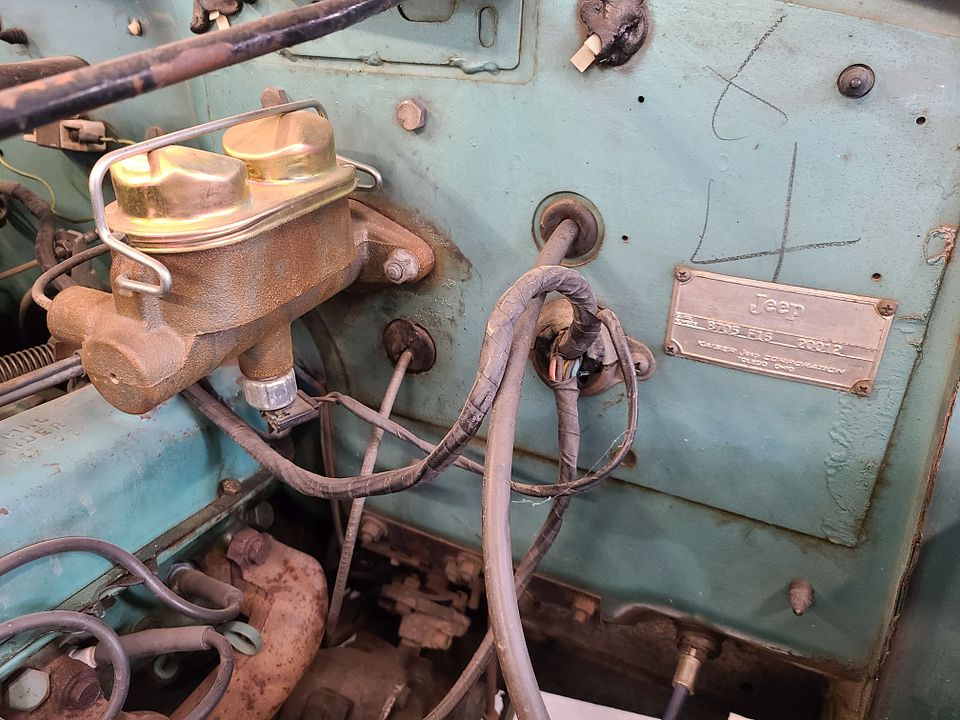

This Jeepster began life with a Jeep family. The original owner had a Jeep dealership in Kentucky, but had this Jeep at his second home in the Colorado Rockies. I picked it up from a collector in Sacramento who had about one hundred cars and trucks in his eclectic collection. There were so many cars that caught my attention, it was hard to focus on the Jeep. The shining star of his collection was a very early Austin Healey 100/4 Le Mans spec car that was originally owned and raced by Augie Pabst. There was also a Porsche 944 that he offered to me for $800, but it was so full of rat turds that I almost threw up.

The Jeepster was very clean and original, but had a few rust spots that would need attention. It ran and drove nicely, and was a perfect candidate for a resto-mod build. A price was settled upon and the Jeep was delivered to my shop the next day.

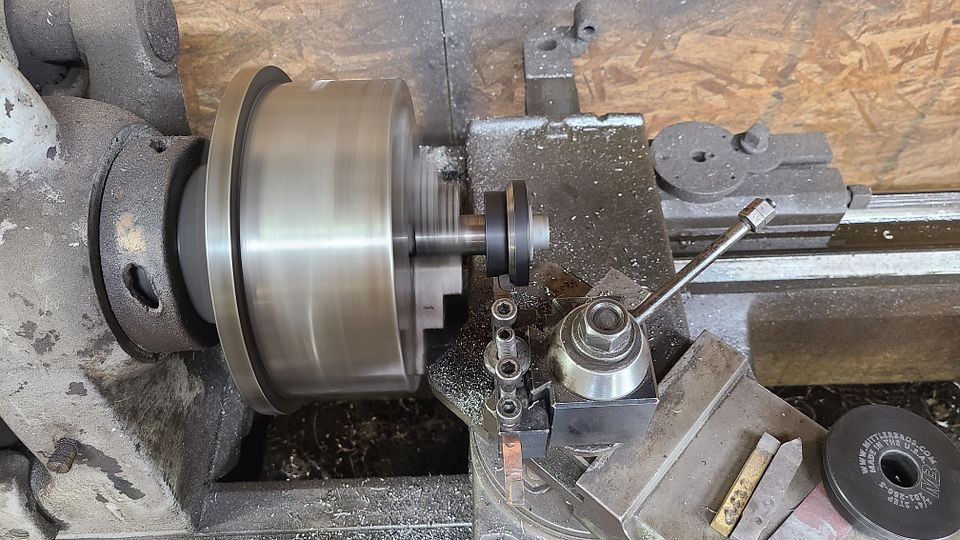

Not really knowing what direction to take the build, we knew that we wanted to keep the basic appearance, but completely restore it and repower it. The original Dauntless V6 was yanked and put on the shelf, and the body was removed for a mock up of the new drivetrain. Ultimately we settled upon a basic LS3 crate motor, which came from Maita Chevrolet in Sac, with the intention of back-dating the look of the engine to the look of a 1960's truck engine, you know, orange, steel valve covers, carburetor intake, etc. For the transmission, it had to have a manual, so a new Tremec TR4050 was ordered from Matthew Jackson at Advance Adapters. After a basic mock up, I knew it was going to be a tight fit.

Let's get started with some pics.

.jpg?width=960&height=720&fit=bounds)

.jpg?width=960&height=720&fit=bounds)