I understand how you feel about the clutch, first time I pushed the pedal in my jeepster with a Chevy 5.3 and an AX15 combo the slave cylinder overextended and fell apart. It gets better, EJS is just one trip, don't do anything bad just to make one deadline. My expected first drive until I actually drove my jeep was over 6 months. Enjoy the trip though.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rango.....1942 Willys MB

- Thread starter Metcalf

- Start date

Metcalf

Expedition Leader

I came up with one more thing to try, but that is about the last thing I am going to do.

It will work fine for running around town without a clutch if I need to. I did that for over a week with a broken clutch finger on my Ford once

Moab will be fun no matter what, always is.

It will work fine for running around town without a clutch if I need to. I did that for over a week with a broken clutch finger on my Ford once

Moab will be fun no matter what, always is.

Metcalf

Expedition Leader

I can't believe that almost worked....

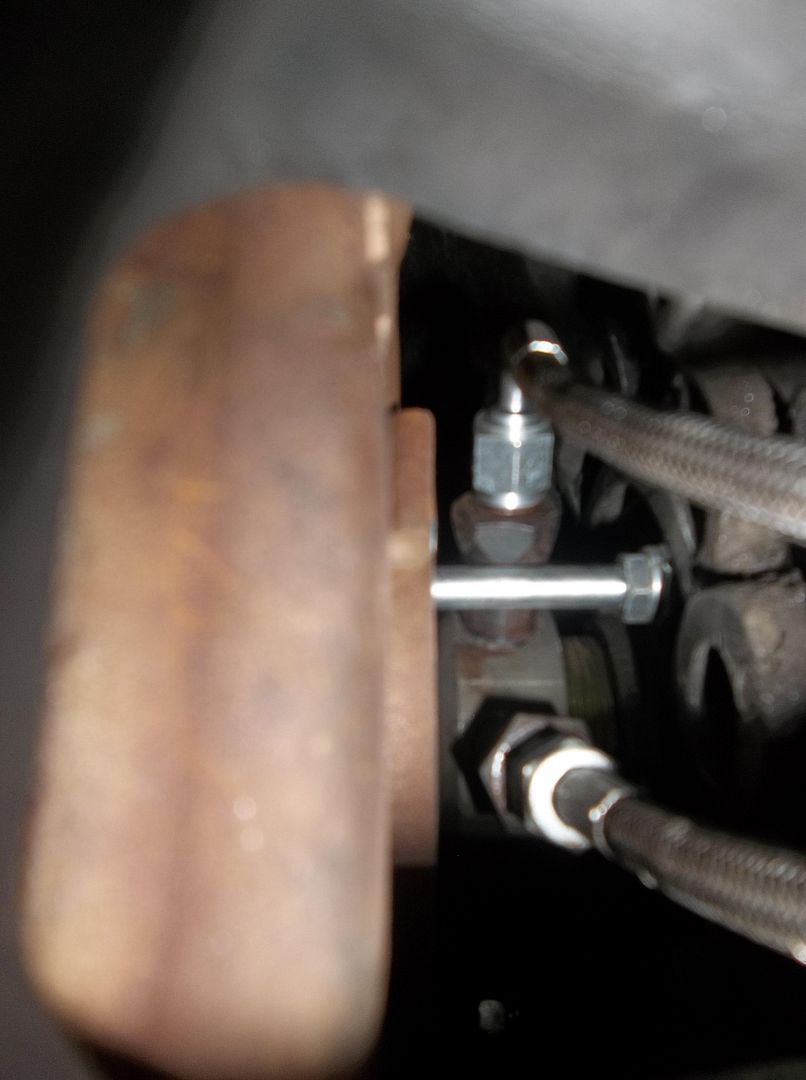

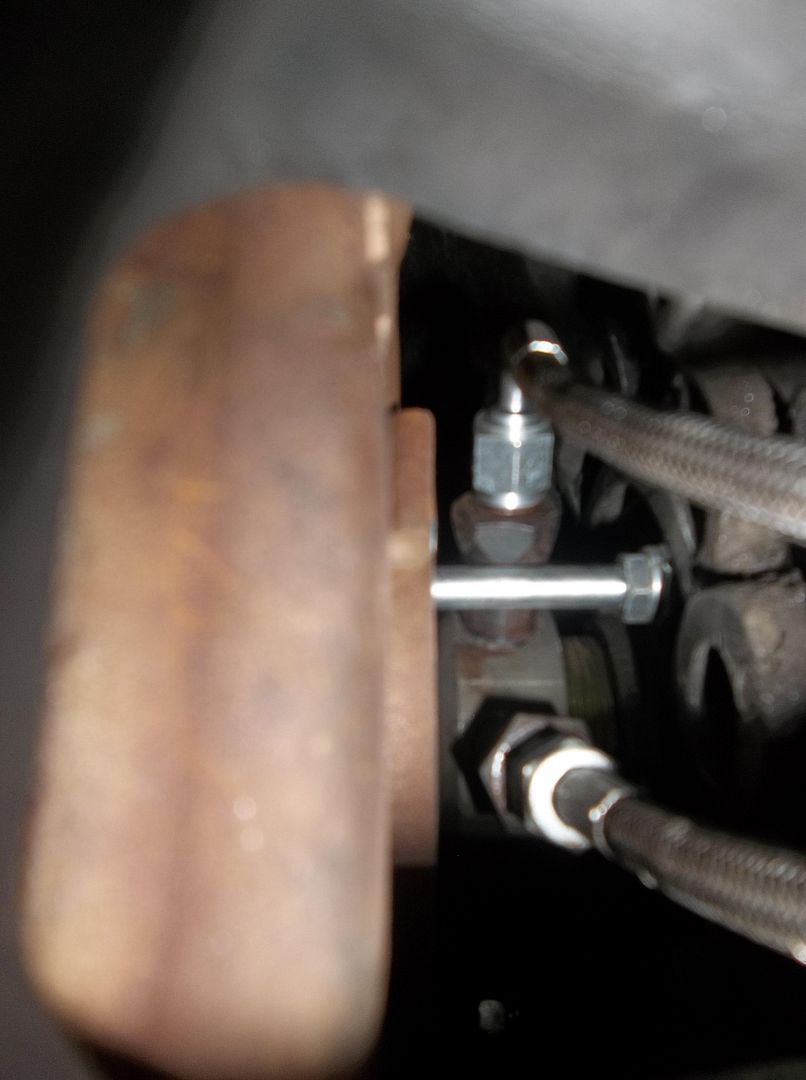

I was able to rotate the AN-4 fitting so the flats where pointed at the pressure plate. This allowed me to get about 3-4 half turns out of the pushrod on the clutch master. Now, the clutch ALMOST disengages before the fittings hit the pressure plate. I can't get it in gear if I start in neutral. I can start the vehicle in gear with the clutch pedal depressed and it doesn't go anywhere. Shifting is better, a little rough but not that bad. I can't go from a forward gear to reverse without shutting the vehicle off. It will be better for the trip. Maybe I can wear a mm off the clutch and it will work fine. I have to make this to tighten the fittings.

I am a firm believer in having around a few sets of those cheap end wrenches you can cut, bend, and weld into interesting contraptions.

I also made a little mount for the breather on the transfer case. I hope this will be high enough to keep it safe and keep the oil from foaming out...

Here is the reverse pressure bleeding contraption I made. I used a little hand sprayer from the garden department and a few fittings to convert it to a 3/16" ID vinyl line.....

Here is a closeup of the conversion fitting. I ended up adding a little epoxy between the plastic factory fittings and the female/female npt fitting. It was a close fit but I didn't want it to leak....

I think it is about ready to go now. Tomorrow I will clean it out a little bit, pack a little bit, maybe tidy up a few things. Not too long till Moab now!

I was able to rotate the AN-4 fitting so the flats where pointed at the pressure plate. This allowed me to get about 3-4 half turns out of the pushrod on the clutch master. Now, the clutch ALMOST disengages before the fittings hit the pressure plate. I can't get it in gear if I start in neutral. I can start the vehicle in gear with the clutch pedal depressed and it doesn't go anywhere. Shifting is better, a little rough but not that bad. I can't go from a forward gear to reverse without shutting the vehicle off. It will be better for the trip. Maybe I can wear a mm off the clutch and it will work fine. I have to make this to tighten the fittings.

I am a firm believer in having around a few sets of those cheap end wrenches you can cut, bend, and weld into interesting contraptions.

I also made a little mount for the breather on the transfer case. I hope this will be high enough to keep it safe and keep the oil from foaming out...

Here is the reverse pressure bleeding contraption I made. I used a little hand sprayer from the garden department and a few fittings to convert it to a 3/16" ID vinyl line.....

Here is a closeup of the conversion fitting. I ended up adding a little epoxy between the plastic factory fittings and the female/female npt fitting. It was a close fit but I didn't want it to leak....

I think it is about ready to go now. Tomorrow I will clean it out a little bit, pack a little bit, maybe tidy up a few things. Not too long till Moab now!

Metcalf

Expedition Leader

So now for some actually techie type stuff and a review of the flatie from the trip...

I went to the trip fully expecting that I wasn't going to have a working clutch and I was going to have to pull the engine when I got home. The clutch was maybe working 70% when I loaded it on the trailer. I could start in gear and the vehicle wouldn't move much. You could go through the forward gears but couldn't be in neutral and then get it in gear. You couldn't go from forward to reverse or vice verse without shutting the motor off.....

Now....somewhere over easter weekend I got a miracle from the flat fender gods and the clutch started working like it was suppose to? Now, my little engineer brain can't really wrap itself around what happened, but after the trail run Thursday afternoon my clutch started working? By the end of the trip it works just like normal. It is slightly notchy and 1st and Reverse are a little tough sometimes, but they are the non-syncro gears. Overall I couldn't be happier. It is definitely workable at this point and only getting better.

I think I basically wore some of the high spots off the new clutch disc giving me the geometry I needed to have a working clutch....

Overall the new transmission and transfer case work really well. The gearing is too high but the planned 4.88 swap will fix that. The new transmission has a SLIGHT leak on the PTO cover. I hadn't even tried messing the bolts yet, it was just a little tiny drop after a full day of driving.

The new transfer case works well. No leaks yet that I can tell. MAYBE a very slight weep on the rear seal but it is hard to tell.

All in all very happy with the new transmission, transfer case, and tunnel.

The vehicle goes down the road a lot better now. The gearing is still off, but driving 55-60 is doable now. You could go a lot faster but it is a flat fender with the tires only at 15psi. I aired them up to 20psi and that seemed to help a lot on the road.

The shifters on the Dana 18 need a 'fix'. They rattle and shake on the highway. I think I am going to pull them, bore them, and press in bushings sized to the pin. These shifters where pretty worn out and loose.

Anyone know if you can build the ends up to fit in the shift rail better? I was thinking about tigging some bronze on the ends and then filing them down till they fit nice, tight, and smooth?

One annoying thing is washboard roads. This was the first time I had it on bad washboards with the tires at street pressure....that was NOT a good combo!

The hood bounced around a little bit and the engine bounced around a little bit. They did this at different times so the air intake would hit the hood. I will have to make that hole a little bigger.

The transmission and transfer case bounce around a little more than I would like on bad washboards. This was on the road up to Area BFE for the races on Saturday. That road will nearly beat a guy in a flat fender to death!

I am thinking about adding a torque link to the drivers side head. Basically something to help hold the motor down a little more than the stock floppy rubber motor mounts? I think I can build a bracket off the head down to the frame with a poly bushed link to help keep the motor from moving too much?

The gas pedal also needs some love. I need to play with the geometry some more. Basically it is inbetween splines for height. The comfy setting only gives me about 3/4 throttle. One up from that gives me full throttle but makes my knee really freaking hurt since I have to hold my foot up too high.

If I had to guess I also think the rear ring and pinion is growling a bit. No big deal I will check everything out when I do my 4.88 swap, add rear seals, etc.

Fun Fun Fun trip.

Thank you to everyone who stopped by to talk to me about my little creation!

I went to the trip fully expecting that I wasn't going to have a working clutch and I was going to have to pull the engine when I got home. The clutch was maybe working 70% when I loaded it on the trailer. I could start in gear and the vehicle wouldn't move much. You could go through the forward gears but couldn't be in neutral and then get it in gear. You couldn't go from forward to reverse or vice verse without shutting the motor off.....

Now....somewhere over easter weekend I got a miracle from the flat fender gods and the clutch started working like it was suppose to? Now, my little engineer brain can't really wrap itself around what happened, but after the trail run Thursday afternoon my clutch started working? By the end of the trip it works just like normal. It is slightly notchy and 1st and Reverse are a little tough sometimes, but they are the non-syncro gears. Overall I couldn't be happier. It is definitely workable at this point and only getting better.

I think I basically wore some of the high spots off the new clutch disc giving me the geometry I needed to have a working clutch....

Overall the new transmission and transfer case work really well. The gearing is too high but the planned 4.88 swap will fix that. The new transmission has a SLIGHT leak on the PTO cover. I hadn't even tried messing the bolts yet, it was just a little tiny drop after a full day of driving.

The new transfer case works well. No leaks yet that I can tell. MAYBE a very slight weep on the rear seal but it is hard to tell.

All in all very happy with the new transmission, transfer case, and tunnel.

The vehicle goes down the road a lot better now. The gearing is still off, but driving 55-60 is doable now. You could go a lot faster but it is a flat fender with the tires only at 15psi. I aired them up to 20psi and that seemed to help a lot on the road.

The shifters on the Dana 18 need a 'fix'. They rattle and shake on the highway. I think I am going to pull them, bore them, and press in bushings sized to the pin. These shifters where pretty worn out and loose.

Anyone know if you can build the ends up to fit in the shift rail better? I was thinking about tigging some bronze on the ends and then filing them down till they fit nice, tight, and smooth?

One annoying thing is washboard roads. This was the first time I had it on bad washboards with the tires at street pressure....that was NOT a good combo!

The hood bounced around a little bit and the engine bounced around a little bit. They did this at different times so the air intake would hit the hood. I will have to make that hole a little bigger.

The transmission and transfer case bounce around a little more than I would like on bad washboards. This was on the road up to Area BFE for the races on Saturday. That road will nearly beat a guy in a flat fender to death!

I am thinking about adding a torque link to the drivers side head. Basically something to help hold the motor down a little more than the stock floppy rubber motor mounts? I think I can build a bracket off the head down to the frame with a poly bushed link to help keep the motor from moving too much?

The gas pedal also needs some love. I need to play with the geometry some more. Basically it is inbetween splines for height. The comfy setting only gives me about 3/4 throttle. One up from that gives me full throttle but makes my knee really freaking hurt since I have to hold my foot up too high.

If I had to guess I also think the rear ring and pinion is growling a bit. No big deal I will check everything out when I do my 4.88 swap, add rear seals, etc.

Fun Fun Fun trip.

Thank you to everyone who stopped by to talk to me about my little creation!

Metcalf

Expedition Leader

I am going to bet the issue with the clutch was air bubbles in the line I have had to deal with several hydraulic clutches, always fighting em till you get the bubbles bled out.

I don't really know for sure, but I am pretty dang sure that the fittings where contacting the pressure plate BUT now they are not and the clutch is working. I think with the new clutch disc it probably had some high spots that wore off rather quickly. This made the clutch disc the right thickness for everything to work again?

Metcalf

Expedition Leader

It was awesome to meet you in person. I wish it wasn't all work for me this year. If I can do a few days earlier next year we should make plans to run a group of flatties. It was awesome to have this parked at the booth.

It was great to meet you. You should bring yours out next year for a run. Even a day or maybe a free evening would be cool!

I came really close to parking my MB next to some of the Jeep Concepts over at there booth to see what would happen

I have a feeling that next year there might be a few more flat fenders at EJS.

Metcalf

Expedition Leader

I guess this is a summary of what I learned in moab and mods I need to make....

Gears. I need some lower axle gears. I was surprised how well it did off road with only 66.5:1 low range. The plan is to install some 4.88 gears in the front and rear diff. That gets me back to the same low end gearing I had with the sm420 at 75.6:1 with 3rd and 4th gear being lower overall, 1st and 2nd are kinda the same as they where.

The questions are still....

4.88 vs 5.38. I'm tempted to just do 5.38s but they are more expensive and weaker. 5.38s would also kill what highway gearing I do have. 55 is a good speed in the flattie. You can go faster but it isn't that relaxing. 4.88s will be 63mph at 3000rpm, and 55mph at 2600rpm. 5.38s would be 58 at 3000rpm and 55 at 2850. I think my engines happy spot is between 2500 and 3000 for pushing 35s. For crawl ratio 5.38s is only 83:1 vs 76:1 for 4.88s. Not that big of a jump. 4.88s are stronger. 4.88s are also a decent amount cheaper.....$100-150 in front.

JK style rear gears vs regular D44 gears? This one is up in the air. I think that the JK gears will be a decent amount more expensive....and the install kit is more expensive and uses some custom parts. Its not like I am running a power house engine, super deep gearing, etc. I am leaning toward regular D44 gears.

Get the front gearset heat treated and/or cyro'd?

http://www.longfieldsuperaxles.com/products.php?product=HEAT-TREAT-&-CRYO-RING-&-PINION

The Dana 30 makes me a little nervous with the 35 spline krawlers. It really isn't that expensive to have it done.....

Rear locker? I am still leaning toward the OX locker. I do think I am going to miss the limited slip a lot of the time, it helps a little but doesn't get in the way. The rear locker will be better overall I think though I think I will have to use it more than I would if I had a good limited slip.....for better or worse. Still trying to allocate enough funds to do it all at once.....

Other 'small' stuff for the future to keep me busy....

-I am going to add rear seals to the floater. I already have them. They are going to go in the full float adapters. I can do that when I do the rear gears.

-front locker. I am happy with it so far. I am tempted to update to a full case locker like a detroit or grizzly at some point. I think that point is at the same time I upgrade the front shafts to alloy units. Grizzly does make a 30 spline version for the dana 30. I have to wonder what will be stronger...a 30 spline inner shaft, 27 spline outer stub, or 4.88 ring and pinion?

-front shafts. I can't afford RCV shafts so I will just be going with alloy shafts that can use the larger 297x size joint. 27 or 30 spline inner shafts? If I go to 30 spline inner shafts I can no longer use my factory small u-joint shafts for spares.....

-t-case shifters. I need to quiet them down. They get annoying on the highway.

-Street tire pressure. 20psi seems to be a good balance? I need to see how the tires wear before I put any long highway miles on them at that pressure. I don't think I need much more than that on a sub 3000lb vehicle?

-Hood hole. I need to make that bigger. The engine and hood move around enough to let them contact each other, especially on washboard roads at street tire pressure.

-Engine torque rod. I need to make a torque rod from the engine to the frame to keep it from flopping around on the factory style rubber mounts. It rocks around pretty good on washboard roads. I think I can go from the drivers side head to the frame pretty easy. I will probably run poly bushings in the link and make it adjustable in length somehow for tension?

-On board air. I need to figure something out. I have a small MV50 compressor that works but I would like a better solution. Ideally I want an engine driven unit. The main problem is that there just isn't a lot of room under the hood. Does anyone know if you can mount a york backwards? Does it matter which way they turn to make air as long as the plumbing is right?

-Make another bikini top. The painters tarp version still works but I need to make something heavier that deals with highway speed better. I need to find some extra thick canvas. I would like to change the mounts on the windshield to the OEM style pin and loop from the MB originally.

-Replace the carb adapter with a phenolic unit. I think that would be better than the aluminum unit. I think at that point I can ditch the thick carb gasket to save about 1/4" of height.

-Redo the fuel pump feed line. I need to make a new hard line from the pump to the carb. I would like to add a better filter, small valve for jet changes, and a fuel pressure regulator.

-Some day I need to upgrade the cooling system. It works pretty well, but I know if I get into 100F+ weather on the road I will need more. I wish I could find an off the shelf aluminum radiator that would work and not cost a fortune. It needs to be less than 16" tall and fit in-between the headlights while missing the steering shaft.....and have a big electric fan..

-I should probably replace my $20 pick and pull distributor with a rebuilt unit.....the oddfire HEI can be a little expensive and or hit or miss in getting the right one from a parts house...

This list could go on and on and on. They are done when they are sold

Gears. I need some lower axle gears. I was surprised how well it did off road with only 66.5:1 low range. The plan is to install some 4.88 gears in the front and rear diff. That gets me back to the same low end gearing I had with the sm420 at 75.6:1 with 3rd and 4th gear being lower overall, 1st and 2nd are kinda the same as they where.

The questions are still....

4.88 vs 5.38. I'm tempted to just do 5.38s but they are more expensive and weaker. 5.38s would also kill what highway gearing I do have. 55 is a good speed in the flattie. You can go faster but it isn't that relaxing. 4.88s will be 63mph at 3000rpm, and 55mph at 2600rpm. 5.38s would be 58 at 3000rpm and 55 at 2850. I think my engines happy spot is between 2500 and 3000 for pushing 35s. For crawl ratio 5.38s is only 83:1 vs 76:1 for 4.88s. Not that big of a jump. 4.88s are stronger. 4.88s are also a decent amount cheaper.....$100-150 in front.

JK style rear gears vs regular D44 gears? This one is up in the air. I think that the JK gears will be a decent amount more expensive....and the install kit is more expensive and uses some custom parts. Its not like I am running a power house engine, super deep gearing, etc. I am leaning toward regular D44 gears.

Get the front gearset heat treated and/or cyro'd?

http://www.longfieldsuperaxles.com/products.php?product=HEAT-TREAT-&-CRYO-RING-&-PINION

The Dana 30 makes me a little nervous with the 35 spline krawlers. It really isn't that expensive to have it done.....

Rear locker? I am still leaning toward the OX locker. I do think I am going to miss the limited slip a lot of the time, it helps a little but doesn't get in the way. The rear locker will be better overall I think though I think I will have to use it more than I would if I had a good limited slip.....for better or worse. Still trying to allocate enough funds to do it all at once.....

Other 'small' stuff for the future to keep me busy....

-I am going to add rear seals to the floater. I already have them. They are going to go in the full float adapters. I can do that when I do the rear gears.

-front locker. I am happy with it so far. I am tempted to update to a full case locker like a detroit or grizzly at some point. I think that point is at the same time I upgrade the front shafts to alloy units. Grizzly does make a 30 spline version for the dana 30. I have to wonder what will be stronger...a 30 spline inner shaft, 27 spline outer stub, or 4.88 ring and pinion?

-front shafts. I can't afford RCV shafts so I will just be going with alloy shafts that can use the larger 297x size joint. 27 or 30 spline inner shafts? If I go to 30 spline inner shafts I can no longer use my factory small u-joint shafts for spares.....

-t-case shifters. I need to quiet them down. They get annoying on the highway.

-Street tire pressure. 20psi seems to be a good balance? I need to see how the tires wear before I put any long highway miles on them at that pressure. I don't think I need much more than that on a sub 3000lb vehicle?

-Hood hole. I need to make that bigger. The engine and hood move around enough to let them contact each other, especially on washboard roads at street tire pressure.

-Engine torque rod. I need to make a torque rod from the engine to the frame to keep it from flopping around on the factory style rubber mounts. It rocks around pretty good on washboard roads. I think I can go from the drivers side head to the frame pretty easy. I will probably run poly bushings in the link and make it adjustable in length somehow for tension?

-On board air. I need to figure something out. I have a small MV50 compressor that works but I would like a better solution. Ideally I want an engine driven unit. The main problem is that there just isn't a lot of room under the hood. Does anyone know if you can mount a york backwards? Does it matter which way they turn to make air as long as the plumbing is right?

-Make another bikini top. The painters tarp version still works but I need to make something heavier that deals with highway speed better. I need to find some extra thick canvas. I would like to change the mounts on the windshield to the OEM style pin and loop from the MB originally.

-Replace the carb adapter with a phenolic unit. I think that would be better than the aluminum unit. I think at that point I can ditch the thick carb gasket to save about 1/4" of height.

-Redo the fuel pump feed line. I need to make a new hard line from the pump to the carb. I would like to add a better filter, small valve for jet changes, and a fuel pressure regulator.

-Some day I need to upgrade the cooling system. It works pretty well, but I know if I get into 100F+ weather on the road I will need more. I wish I could find an off the shelf aluminum radiator that would work and not cost a fortune. It needs to be less than 16" tall and fit in-between the headlights while missing the steering shaft.....and have a big electric fan..

-I should probably replace my $20 pick and pull distributor with a rebuilt unit.....the oddfire HEI can be a little expensive and or hit or miss in getting the right one from a parts house...

This list could go on and on and on. They are done when they are sold

MrBeast

Explorer

I don't really know for sure, but I am pretty dang sure that the fittings where contacting the pressure plate BUT now they are not and the clutch is working. I think with the new clutch disc it probably had some high spots that wore off rather quickly. This made the clutch disc the right thickness for everything to work again?

I'd still say air bubbles, it would happen on my wreckers when we had to replace the master/slave cylinder, it would take hours upon hours to get the air bubbles out, sometimes days, all it takes is a couple of tiny bubbles trapped in there and the clutch wont function properly. The symptoms are exactly as you stated, what I wound up having to do to make it right was to use a vacuum bleeder from the master cylinder, id use one of the small cone shaped attachments that came with it and put it in the port and suck the bubbles up to the MC with the reservoir topped off, even after pulling 34" of vacuum on it I would have to repeat the process 30-50 times to get the bubbles out, and often id have to drive it in between because one high spot in the line would trap bubbles and the only thing that would bring them out of that high spot was the vehicle moving shaking them loose.

It was a really miserable adventure when I had to do it. Got a lot of practice at it though.

Forum statistics

Members online

- Screwfly

- Imgoingonanadvencha

- jethro5

- mark5280

- sfisher

- red9xs

- KelliT

- Norcalassassin

- mangymarmot

- llamalander

- dizzydom

- AKU500

- Welder Dude 76

- rruff

- Hyperdrive

- Lee

- emtmark

- ttn333

- ColoradoToy91

- Byrdseye

- SolBeach

- NOPEC

- Antwon412

- osukj04

- webfoots

- bry2

- abunker

- Lanceski

- tjalward

- Grimreaper333

- no_whereman

- GHI

- jerry.jones.7330

- Jake's_dad

- hoodoo

- bherwig

- James101

- DirtWhiskey

- D.C. Benny

Total: 754 (members: 45, guests: 709)