You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Safari Cab" modular hardtop project

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

This set of photos shows four different lengths of Safari Cab made from basically the same parts, just different center side panels. The roof has been digitally shortened, but the same roof master would be cut/shortened to make new masters for the different tops, so the digital process isn't that much different than what will happen to the actual masters.

Top left, a half cab the same length as the factory Scrambler half cab; also the same length as the Gaucho cab.

Top right, a half cab the same length as the Retro Wrangler cab; also the same length as the Brute cab.

Middle - TJ/YJ/CJ full cab (same photo I posted yesterday).

Bottom - Wrangler Unlimited LJ full cab.

Unfortunately I ran out of plywood before I could make the center side panel module for the Scrambler full cab.

Top left, a half cab the same length as the factory Scrambler half cab; also the same length as the Gaucho cab.

Top right, a half cab the same length as the Retro Wrangler cab; also the same length as the Brute cab.

Middle - TJ/YJ/CJ full cab (same photo I posted yesterday).

Bottom - Wrangler Unlimited LJ full cab.

Unfortunately I ran out of plywood before I could make the center side panel module for the Scrambler full cab.

86cj

Explorer

I'm working with the company to put a survey together we'll ask folks following this thread to respond to - window types will be covered in the survey, so please fill out the survey when we post it.

And if in the end the company decides to build the tops with something other than your first choice in windows, then you could always buy a van version of the top with no side windows and put in whatever type of windows you'd like...

---------------------

Questions about the Safari Cab? Try here first: Safari Cab FAQ

I like this idea alot!! This would be my choice...................

A person could put different windows on either side, maybee even a Windoor swing up type. The actual wood LJ mock up shown above will look just fine with black window frames, I thought it might look to busy.

Great work, good luck....

jscherb

Expedition Leader

All of the concept drawings I've shown so far have the hardtop being the same color as the Jeep, which is how I plan to paint mine. But if the hardtop is to come to market, I doubt it is practical for the company to offer it in every possible factory body color, nor is it practical to ship it only in primer and expect every owner to paint it their body color.

So I've been doing a lot of "color studies" in the past two weeks - drawings of Jeeps in various factory colors with Safari Cabs in a range of different colors, including black, white, khaki, light khaki and spice... and even some "two-tone" hardtops, with white roof panels and different side colors. I'm going to post a few soon, but there are FAR too many combinations for me to post, so before I post any, I'd like to hear from you.

Other than making the top the same color as the Jeep, what colors do you think might look good? I'd like to see if you've got any ideas I haven't tried yet, and then I'll post the best of what I've come up with and the best that you guys come up with for comment.

Any thoughts on colors for me to add to the collection of color study drawings I'm doing?

So I've been doing a lot of "color studies" in the past two weeks - drawings of Jeeps in various factory colors with Safari Cabs in a range of different colors, including black, white, khaki, light khaki and spice... and even some "two-tone" hardtops, with white roof panels and different side colors. I'm going to post a few soon, but there are FAR too many combinations for me to post, so before I post any, I'd like to hear from you.

Other than making the top the same color as the Jeep, what colors do you think might look good? I'd like to see if you've got any ideas I haven't tried yet, and then I'll post the best of what I've come up with and the best that you guys come up with for comment.

Any thoughts on colors for me to add to the collection of color study drawings I'm doing?

AlwaysExplr87

Member

Regarding the color, you could offer a base white or black with the option to have it painted to match for a higher price. Im not sure how this would work out logisticaly but it would allow you to offer products at different price points that would apeal to a larger market.

edit: Something to consider about trying to offer colors is it is really hard to get a good match. Especially considering the wide range of vehicles and years you are offering this for. Im fine with things not matching perfectly and many others are too, however there are alot of people who want an exact match to their truck. It might be better to offer the top in colors similar to those offered in the factory hard tops. There are several colors to match whatever color palet and people are familiar with the two tone look for hardtops so I doubt many people would be unhappy without color matched tops.

Just wanted to say I like the idea of the van side cab and adding your own windows.

edit: Something to consider about trying to offer colors is it is really hard to get a good match. Especially considering the wide range of vehicles and years you are offering this for. Im fine with things not matching perfectly and many others are too, however there are alot of people who want an exact match to their truck. It might be better to offer the top in colors similar to those offered in the factory hard tops. There are several colors to match whatever color palet and people are familiar with the two tone look for hardtops so I doubt many people would be unhappy without color matched tops.

Just wanted to say I like the idea of the van side cab and adding your own windows.

Last edited:

jscherb

Expedition Leader

Color matching is one reason I doubt the company would want to offer the top in factory colors. I'm sure they would be happy to offer it in primer so people could deal with the color match themselvesSomething to consider about trying to offer colors is it is really hard to get a good match. Especially considering the wide range of vehicles and years you are offering this for. Im fine with things not matching perfectly and many others are too, however there are alot of people who want an exact match to their truck. It might be better to offer the top in colors similar to those offered in the factory hard tops. There are several colors to match whatever color palet and people are familiar with the two tone look for hardtops so I doubt many people would be unhappy without color matched tops.

Perhaps it could be offered in several "van" configurations:Just wanted to say I like the idea of the van side cab and adding your own windows.

- With no windows at all

- With just the rear door window installed but no side windows

- With the rear door and rear opera windows installed but no side windows.

jscherb

Expedition Leader

Tomorrow I'll be working on the inner mold master for the rear door, so I'm posting my preliminary component layout design for comments.

I've laid out the parts to accept a "Mighty Wiper" from Pacific Western Design (www.pacificwesterndesign.com); it's a very small and light motor that will fit well in the door upper. It is compatible with the factory TJ hardtop wiper wiring.

A nozzle for the rear window washer would be mounted on the rear wall of the hardtop, not on the door. it would be above and inboard of the rear opera window on the driver's side, and a short hose extension is all that would be required to connect it to the factory hardtop washer hose. I haven't sourced a nozzle yet.

For pre-2003 Jeeps that do not have venting in the tailgate, there will be a series of louvers on the inside of the door, feeding an external vent. The vent is from a second-generation Chevy S-10; unfortunately the 2003 and later factory Jeep tailgate vent is too large to fit in this door.

And there's also a location where 4" speakers could be mounted, although I'm not sure many people would be interested in mounting speakers there.

I'm not sure what, if any of these features would be "factory installed" by the company, but in the event the company decided not to offer the features they could be installed by the Jeep owner.

The drawing shows the location of the mounting hardware for using the door in the barn door configuration, but all of the above features could also be used in the liftgate configuration.

And I've posted the below drawing before, but I'm including it in this post again for reference. It doesn't show all the detail of the above drawing.

I've laid out the parts to accept a "Mighty Wiper" from Pacific Western Design (www.pacificwesterndesign.com); it's a very small and light motor that will fit well in the door upper. It is compatible with the factory TJ hardtop wiper wiring.

A nozzle for the rear window washer would be mounted on the rear wall of the hardtop, not on the door. it would be above and inboard of the rear opera window on the driver's side, and a short hose extension is all that would be required to connect it to the factory hardtop washer hose. I haven't sourced a nozzle yet.

For pre-2003 Jeeps that do not have venting in the tailgate, there will be a series of louvers on the inside of the door, feeding an external vent. The vent is from a second-generation Chevy S-10; unfortunately the 2003 and later factory Jeep tailgate vent is too large to fit in this door.

And there's also a location where 4" speakers could be mounted, although I'm not sure many people would be interested in mounting speakers there.

I'm not sure what, if any of these features would be "factory installed" by the company, but in the event the company decided not to offer the features they could be installed by the Jeep owner.

The drawing shows the location of the mounting hardware for using the door in the barn door configuration, but all of the above features could also be used in the liftgate configuration.

And I've posted the below drawing before, but I'm including it in this post again for reference. It doesn't show all the detail of the above drawing.

BPage

Adventurer

Awesome build... just had a chance to read from start to finish and I am a fan!!!

My $0.02

1. go with standard black color, if people are set on color matching, they can have their local paint shop do that.

2. Van style sides is the way to go. I personal want flip up side windows like Jim from PA was talking about, but I know I am in the minority. plus you get into the discussion of sliding vs. solid windows, bug screens vs. open. If they sell van sides, people can modify it as they see fit.

3. The barn door with a window is a great idea. You can still see out the back, and your rear gate opens with the window.

Again, great build, I am waiting to hear what company your working on, and when they plan on pricing it and releasing it.

Thanks for all your hard work, and sharing it with us.

My $0.02

1. go with standard black color, if people are set on color matching, they can have their local paint shop do that.

2. Van style sides is the way to go. I personal want flip up side windows like Jim from PA was talking about, but I know I am in the minority. plus you get into the discussion of sliding vs. solid windows, bug screens vs. open. If they sell van sides, people can modify it as they see fit.

3. The barn door with a window is a great idea. You can still see out the back, and your rear gate opens with the window.

Again, great build, I am waiting to hear what company your working on, and when they plan on pricing it and releasing it.

Thanks for all your hard work, and sharing it with us.

Last edited:

Jeff, love the detailed drawings for the barn door. Slick to include the wiper like that!

One other thing that came to mind in thinking about what it will be like to have that mounted on the tailgate. You'll probably want to have a latching/strut mechanism to hold the gate fully open. In any kind of wind, you've got what amounts to a giant sail now and it's already bad with just the gate and spare in my experience.

One other thing that came to mind in thinking about what it will be like to have that mounted on the tailgate. You'll probably want to have a latching/strut mechanism to hold the gate fully open. In any kind of wind, you've got what amounts to a giant sail now and it's already bad with just the gate and spare in my experience.

nwoods

Expedition Leader

One thing that keeps going through my mind along with built in lighting, is tie down points. This top will be more or less permanently installed by whoever buys it. Having lashing points or hardend points with threaded inserts places strategically throughout the interior (near the upper corners for example), would be very handy.

A question I've seen asked here a few times and not answered to my knowledge is about strength. On the LJ top you really have a lot of window area. How are the narrow pilasters and corners reinforced? What short of weight capacity are you aiming for?

A question I've seen asked here a few times and not answered to my knowledge is about strength. On the LJ top you really have a lot of window area. How are the narrow pilasters and corners reinforced? What short of weight capacity are you aiming for?

24HOURSOFNEVADA

Expedition Leader

I like the "Van" sides better than anything else you've posted. Also, I've noticed in your drawings that there is usually a speaker recess. How deep are you planning on making these doors? What provisions will there be to allow concealed wiring?

jscherb

Expedition Leader

Thanks Eric. I had always planned to install a wiper in the rear door of my World Cab, even got one out of an Isuzu Trooper at the Pick-n-Pull for it, just never got around to installing it.Jeff, love the detailed drawings for the barn door. Slick to include the wiper like that!

I spent some time on the phone with the tech people at Pacific Design yesterday and they don't think their wiper is strong enough for this application; they don't want me to use anything more than a 9" wiper blade on it. But they recommended another company that has one that'll do the job and will just fit. AM Equipment's model 230 marine wiper will do the job (http://www.amequipment.com/03_marine.html).

One other thing that came to mind in thinking about what it will be like to have that mounted on the tailgate. You'll probably want to have a latching/strut mechanism to hold the gate fully open. In any kind of wind, you've got what amounts to a giant sail now and it's already bad with just the gate and spare in my experience.

There's one on the market from Rugged Ridge, so rather than me engineering one, if people find that it's necessary maybe we could just recommend they buy that one?

Hmmm, on second thought, the Rugged Ridge unit may not fit with the door attachment hardware I'm planning... well we'll have to get a door installed and see if something is necessary. I never felt the need for one on my World Cab, but maybe the TJ hinges swing easier than the WC hinges and it could be necessary.

jscherb

Expedition Leader

I like the "Van" sides better than anything else you've posted. Also, I've noticed in your drawings that there is usually a speaker recess. How deep are you planning on making these doors? What provisions will there be to allow concealed wiring?

At the point in the doors where I've drawn speakers, there will be enough depth to install typical 4" speakers. I'm making the lower part of the door a bit thicker than the tailgate for a number of reasons including strength; room to install the mounting hardware to attach it to the tailgate; and space to include a wiper motor. I'll have the mold master done within a few days and you'll be able to see what it looks like. I don't plan to make any special provisions in the mold for speaker mounting, it just turns out that there's enough room inside the door at those points and I won't use the room for anything else. Whether anyone would actually want to mount speakers there I don't know.

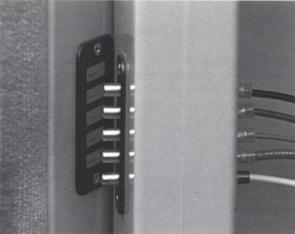

There will be room inside the lower part of the door for wiring; it would be up to the end user to decide how to get the wiring from the body to the tailgate. I recently installed a power lock in my LJ tailgate and I used an extra set of factory contacts to bring power to the tailgate, but when I do the Safari Cab door and wiper on the LJ, I'll probably have to replace that extra set of contacts with something like this set of aftermarket contacts:

You could also use wire looms (http://www.electric-life.com/shopdisplayproducts.asp?id=9&cat=Wire+Looms).

I suspect the company would probably leave the wiring to the end user rather than offering "plug and play" wiring harnesses.

---------------------

Questions about the Safari Cab? Try here first: Safari Cab FAQ

---------------------

jscherb

Expedition Leader

I don't doubt that many people would run their Safari Cabs full time, but I plan to swap mine on and off every year - I want to run with my soft top in the summer and the Safari Cab in the colder months. I'm designing the Safari Cab so that it will be easy to swap on and off.One thing that keeps going through my mind along with built in lighting, is tie down points. This top will be more or less permanently installed by whoever buys it. Having lashing points or hardend points with threaded inserts places strategically throughout the interior (near the upper corners for example), would be very handy.

I'm not familiar with the type of lashing point you're referring to, can you find me some photos? If I know what you're looking for, maybe I can add them.

There will be reinforcements built into the necessary places in the top; I haven't posted any drawings of the internal reinforcements.A question I've seen asked here a few times and not answered to my knowledge is about strength. On the LJ top you really have a lot of window area. How are the narrow pilasters and corners reinforced? What short of weight capacity are you aiming for?

There will also be reinforcing ribs in the roof panel; I expect the roof panel in base form to support about 150 pounds on a Cherokee-style roof rack. We will of course test that before building the production tops.

With the optional internal roll-bar-based support system I've designed, I would expect load capacity several times that; I don't really want to specify an exact weight at this point because I'm concerned more about the center of gravity of the Jeep than the actual weight capacity of what I've designed. I don't want to say xxx pounds, and then have someone go out and roll their Jeep because they put enough up there to move the CofG high enough to promote rollovers.

Last edited:

jscherb

Expedition Leader

This is slightly off topic, but I'd like to share with you the results of my first fiberglass project... last fall I decided to make new fenders out of fiberglass for my Retro Wrangler pickup; I wanted to change a few dimensions by a half inch or so to make the size of the fenders *perfect* - the original metal fenders I made were very nice, but I guess I'm a bit obsessive  . So I made a new master, and a mold, and I molded two new fenders. I prepped them for paint in January, and dropped them off at the body shop then for color and clear coats. They finally painted them this morning (they like me, but I'm not a priority compared to their collision work).

. So I made a new master, and a mold, and I molded two new fenders. I prepped them for paint in January, and dropped them off at the body shop then for color and clear coats. They finally painted them this morning (they like me, but I'm not a priority compared to their collision work).

Anyway, here are some photos of the almost-finished new fiberglass fenders for the Retro. All they need as to have the inside undercoated, and the paint buffed, and I'll be able to install them.

My second fiberglass project was the fenders for the Gaucho, which turned out nicer than the above Retro fenders (in 'glass anyway, they haven't been painted yet).

Now that I'm "experienced" with fiberglass, I expect the Safari Cab fiberglass work will be even nicer than this as well.

Anyway, here are some photos of the almost-finished new fiberglass fenders for the Retro. All they need as to have the inside undercoated, and the paint buffed, and I'll be able to install them.

My second fiberglass project was the fenders for the Gaucho, which turned out nicer than the above Retro fenders (in 'glass anyway, they haven't been painted yet).

Now that I'm "experienced" with fiberglass, I expect the Safari Cab fiberglass work will be even nicer than this as well.