dzzz

™

Are you planning on just one bike? If there was two I would lean toward the use of a simple platform/cage that allowed you to load/unload both bikes ( or cargo ) all at the same time.

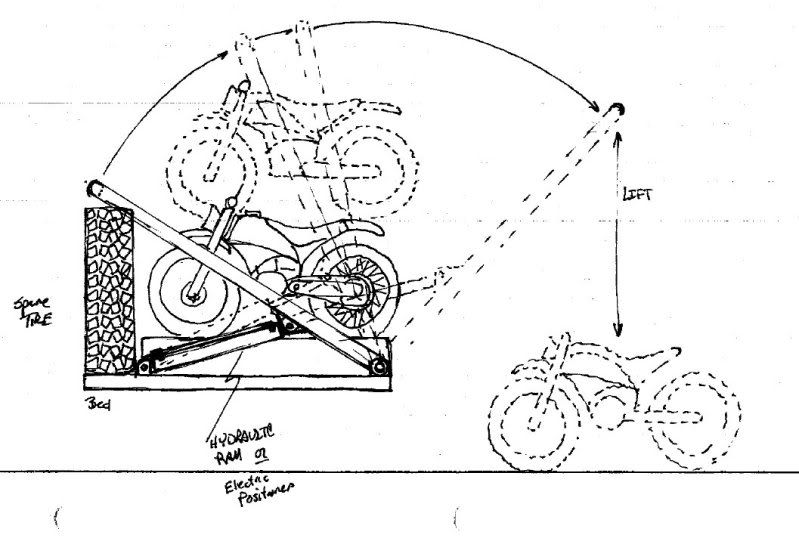

I think using a hydraulic ram to control the u-frame crane would be the best. I think if you limited the angles so the force on the frame was minimized you could get away with running a single ram on one side. The frame would have to be slightly stronger, but you would save a lot of complexity. A single hydraulic circuit with a spring loaded closed center valve would be pretty darn simple. That could be mounted out of the way under the bed in a little lock box.

...................

I don't think a cage changes the design, it could be an add-on.

The hydraulic control is already in the cabin by a joy stick Literally all it takes hardware-wise is pluging the line into quick disconnects. The parameters of the lines are set up on the control panel and it's good to go.

Is there any practical problem of controlling to rams on one circuit? It doesn't seem to me that dual rams on a front end loader have any special circuit balancing. Perhaps equal line length out of the manifold? Or is it more complicated?