PetitePatate

New member

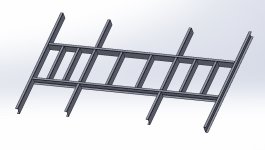

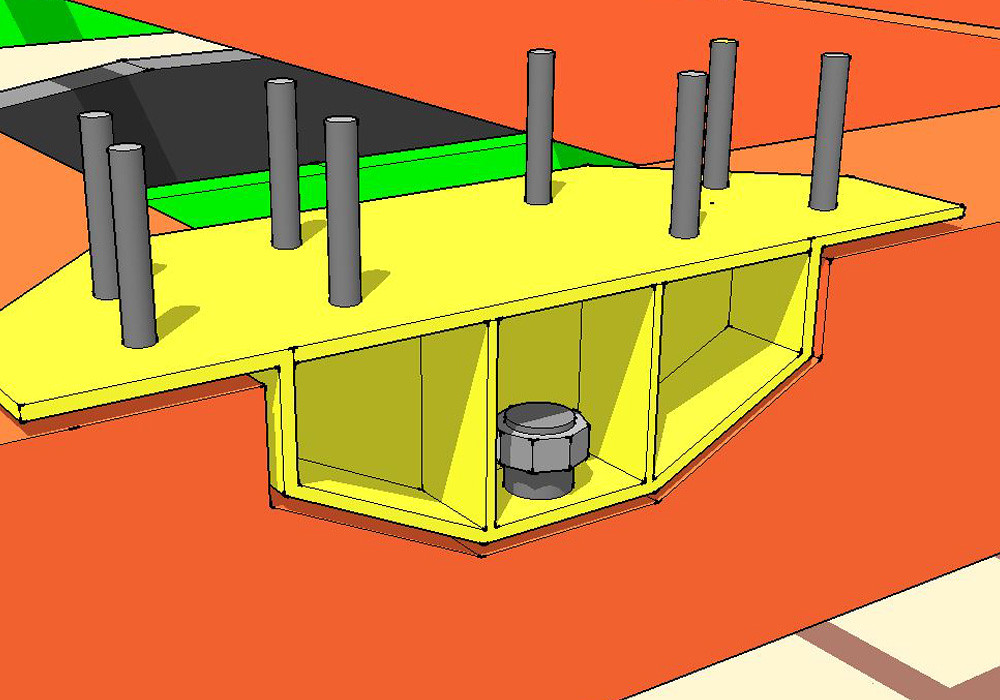

I’m currently grinding the box off my Unimog 1300L with the plan of keeping the subframe, next month I’m going to be putting together a small composite box made from 2 sheets of nidacore.

I’m wondering if it would make sense to put some bands of rubber between the subframe and composite box?

Would this help with the vibrations that happen sometimes or am I just over complicating things for myself?

In order to attach the camper to the subframe we are making little fibreglass “legs” on the camper and bolting it horizontally through the subframe. I was considering putting bushings on the subframe at these attachments, but the guy that’s helping me with the composite box says that would not be necessary.

I’m wondering if it would make sense to put some bands of rubber between the subframe and composite box?

Would this help with the vibrations that happen sometimes or am I just over complicating things for myself?

In order to attach the camper to the subframe we are making little fibreglass “legs” on the camper and bolting it horizontally through the subframe. I was considering putting bushings on the subframe at these attachments, but the guy that’s helping me with the composite box says that would not be necessary.