Toy-Roverlander

Adventurer

Ok, for the shockie experts among us..

I've got a SIIa 109" stationwagon.

This Landy is completely different from your standard 109" or military/one-ton.

The problem is in the rear suspension.

The front mount of the leafspring has been lowered by 3cm

The rear shackle mount is lowered by 5cm

Reason I guess (PO has done it) is to lift the rear of the vehicle (the chassis is a lengthened 88" chassis, with a self-made mid and rear end. Made to very high standards.) So with completely flat springs the Landy sat level.

Now with the para's fitted the rear is lifted a fair bit, like 9cm.

Today I wanted to put the shockies on there, I bought those Pro Comp ES3000 ones, and they don't fit... they're too tall.

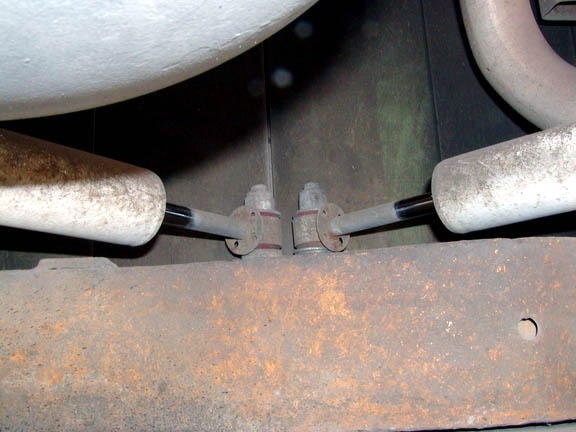

When the chassis was made, not only did they lower the leaf and shackle mounts, but they lowered the shockabsorber mount as well.. Instead of it sitting above the chassis rail, nearly touching the bottom of the tub, mine sits in the main chassis rail, with the top of the shockie flush with the top of the chassis rail on the bit where it slopes down.

So, my problem..

ES3000's are too long. When fitted they can only compress about 2cm before bottoming out.

Original shockies are the right length but they don't really have the rating for soft parabolics.

So what to do? Are adjustable shocks available in standard lenght? Gas shocks perhaps. I saw that Monroe's are available, or DeCarbon. I believe both are gasdampers.

I know ****all about shockies to be honest.

What to do?

I really don't want to change the top mount of the shockabsorber.

Many thanks!

Koos

PS, I've just ordered some original ones, just to get me on the road. My old springs were incredibely soft and it worked, although it needed some tougher shockies...

I've got a SIIa 109" stationwagon.

This Landy is completely different from your standard 109" or military/one-ton.

The problem is in the rear suspension.

The front mount of the leafspring has been lowered by 3cm

The rear shackle mount is lowered by 5cm

Reason I guess (PO has done it) is to lift the rear of the vehicle (the chassis is a lengthened 88" chassis, with a self-made mid and rear end. Made to very high standards.) So with completely flat springs the Landy sat level.

Now with the para's fitted the rear is lifted a fair bit, like 9cm.

Today I wanted to put the shockies on there, I bought those Pro Comp ES3000 ones, and they don't fit... they're too tall.

When the chassis was made, not only did they lower the leaf and shackle mounts, but they lowered the shockabsorber mount as well.. Instead of it sitting above the chassis rail, nearly touching the bottom of the tub, mine sits in the main chassis rail, with the top of the shockie flush with the top of the chassis rail on the bit where it slopes down.

So, my problem..

ES3000's are too long. When fitted they can only compress about 2cm before bottoming out.

Original shockies are the right length but they don't really have the rating for soft parabolics.

So what to do? Are adjustable shocks available in standard lenght? Gas shocks perhaps. I saw that Monroe's are available, or DeCarbon. I believe both are gasdampers.

I know ****all about shockies to be honest.

What to do?

I really don't want to change the top mount of the shockabsorber.

Many thanks!

Koos

PS, I've just ordered some original ones, just to get me on the road. My old springs were incredibely soft and it worked, although it needed some tougher shockies...