Hey guys, back again , in my converted cargo trailer the circuits are piling up,lol, here’s the question, here’s a few examples of what I’m not sure of switch wise, small Chinese diesel heater, small push up activated shower exhaust fan, electric tongue jack,water pumps shower and sink , I know their activated by water demand I think haha, small marine fan , Maxx air fan, I know that of course that all these have on/ off switches but ? Thoughts

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What doesn’t need to get switched in a D/C system

- Thread starter Roktman

- Start date

Dave in AZ

Active member

All the circuits should be fused or protected by a circuit breaker at least. This should be between power source and the load. The fuse protects the wire, size it at 125% the wire ampacity. I use a 12 circuit BlueSea fuseblock. If your power source is a "power station" and not a battery, it is possible the various plug ports are already overcurrent protected, negating need for another fuse/cb. Depends on the power station and port you're using.

However, you can also use a switched circuit breaker panel. This is nice as you can reset them easily, easier to see if popped/blown than a fuse, and can use it as on/off switch if so rated, and most dc ones seem to be.

Basically you want a switch on any circuit that could conceivably turn on and either drain your battery, or cause problems like water pump. So:

1. Always put a switch on water pump so you don't risk it running, and also so it doesn't turn on, pressurize lines, then turn off (as it is designed to do). Best not to drive around bumping and vibrating with pressurized water lines.

2. Things with own switches that you'll notice if on, like lights and fans, don't need another switch. If that bathroom fan might get jiggled up to on position, switch it.

3. Chinese diesel heater-- if you ever turn off power to it without letting it do its full shutdown cycle, you will cause yourself problems and future errors. So you for sure DON'T want an easily accessible switch. However, you also don't want a 460f heat source just one wire jiggle away from turning on either, so I place a switch I can depower it, but make it hard to touch so I will never reach out by mistake and turn it off when I want the heater off... yeah, I did that a few times. The added fact these come with remote fobs and bluetooth phone apps that let you turn it on remotely, and have like zero IT security controls, makes me want that thing unpowered when not in use--did you change your app password from factory and also change the remote dip switches from factory? I turned mine on once on back patio just walking around with remote fob in my pocket.

4. High ampacity high demand motors like lift jack-- make sure there is a cutoff fuse or switch somewhere! If a motor tries to spin but can't, it will pull enough amps trying to start to melt the wires. I had a trolling motor on my duck kayak, once when I shoved it up into weeds on bank, the rotating handle on switch got turned on, and the prop was blocked from spinning. I didn't have it fused, it was an 80 lb kayak... all the wires caught fire and the lead battery terminals melted. I turned around from throwing a decoy like 1 min later to flaming wires and bushes and molten lead running into my plastic boat! Ended ok, but convinced me that 12v dc motors that may not turn, absolutely need a fuse. Later found fine print on trolling motor directed that, though its wires didn't come with one...

Truthfully, I actually run all circuits through my dc fuseblock, and then power that with one 10awg 30A 12v cable from my Pecron 1536Wh power station. So I can depower everything by just pulling 1 connector, an xt60 plug. Which I do. This basically solves most of my issues for stuff accidentally running while driving.

However, you can also use a switched circuit breaker panel. This is nice as you can reset them easily, easier to see if popped/blown than a fuse, and can use it as on/off switch if so rated, and most dc ones seem to be.

Basically you want a switch on any circuit that could conceivably turn on and either drain your battery, or cause problems like water pump. So:

1. Always put a switch on water pump so you don't risk it running, and also so it doesn't turn on, pressurize lines, then turn off (as it is designed to do). Best not to drive around bumping and vibrating with pressurized water lines.

2. Things with own switches that you'll notice if on, like lights and fans, don't need another switch. If that bathroom fan might get jiggled up to on position, switch it.

3. Chinese diesel heater-- if you ever turn off power to it without letting it do its full shutdown cycle, you will cause yourself problems and future errors. So you for sure DON'T want an easily accessible switch. However, you also don't want a 460f heat source just one wire jiggle away from turning on either, so I place a switch I can depower it, but make it hard to touch so I will never reach out by mistake and turn it off when I want the heater off... yeah, I did that a few times. The added fact these come with remote fobs and bluetooth phone apps that let you turn it on remotely, and have like zero IT security controls, makes me want that thing unpowered when not in use--did you change your app password from factory and also change the remote dip switches from factory? I turned mine on once on back patio just walking around with remote fob in my pocket.

4. High ampacity high demand motors like lift jack-- make sure there is a cutoff fuse or switch somewhere! If a motor tries to spin but can't, it will pull enough amps trying to start to melt the wires. I had a trolling motor on my duck kayak, once when I shoved it up into weeds on bank, the rotating handle on switch got turned on, and the prop was blocked from spinning. I didn't have it fused, it was an 80 lb kayak... all the wires caught fire and the lead battery terminals melted. I turned around from throwing a decoy like 1 min later to flaming wires and bushes and molten lead running into my plastic boat! Ended ok, but convinced me that 12v dc motors that may not turn, absolutely need a fuse. Later found fine print on trolling motor directed that, though its wires didn't come with one...

Truthfully, I actually run all circuits through my dc fuseblock, and then power that with one 10awg 30A 12v cable from my Pecron 1536Wh power station. So I can depower everything by just pulling 1 connector, an xt60 plug. Which I do. This basically solves most of my issues for stuff accidentally running while driving.

Last edited:

If you are running into layout / placement / wire routing issues, there are a few things you might do to help yourself…. Use with caution if you are uncertain or uncomfortable calculating loads:

Either power or ground busses can save a lot of back and forth wire routing, although the end up being very large in comparison to the other wires that would be needed.

You can also put the switches near the appliance or in the ground side where that makes sense.

For instance, I have an LED circuit with multiple switched grounds so I can turn it on in different places.

Either power or ground busses can save a lot of back and forth wire routing, although the end up being very large in comparison to the other wires that would be needed.

You can also put the switches near the appliance or in the ground side where that makes sense.

For instance, I have an LED circuit with multiple switched grounds so I can turn it on in different places.

DaveInDenver

Middle Income Semi-Redneck

There are reasons and even advantages (in the case of electronic switches it's basically mandatory to do low side practically) to switching the returns (negative) on loads but be aware that there is a safety aspect.

When you break the return side of a circuit what is left is a hot side just waiting to be shorted and you've surrounded it with a lot of chassis and body that is that path.

If you put the switch on that side don't also move the fuse or breaker to the return, either deliberately or unintentionally.

When you break the return side of a circuit what is left is a hot side just waiting to be shorted and you've surrounded it with a lot of chassis and body that is that path.

If you put the switch on that side don't also move the fuse or breaker to the return, either deliberately or unintentionally.

Yea I did, I got the ANKER solid 767, but I’ve also decided to go with lithium battery’s , kinda of a classic 400 watt solar set up and use the ANKER for a truck pop up camper and /or for a back up in the cargo conversion trailerI don’t remember but did you finalize/buy your power source?

Can you or someone elaborate maybe with a schematic … maybe,lol, no really, at this point hears where I’m about to be at,There are reasons and even advantages (in the case of electronic switches it's basically mandatory to do low side practically) to switching the returns (negative) on loads but be aware that there is a safety aspect.

When you break the return side of a circuit what is left is a hot side just waiting to be shorted and you've surrounded it with a lot of chassis and body that is that path.

If you put the switch on that side don't also move the fuse or breaker to the return, either deliberately or unintentionally.

1) I have wire running from appliances to two bluesea fuse boxes , one on each side of trailer ( wire is correctly sized):

2) for switches I’m using the nilight 6 gang on/off rocker type switches , cutting into the wire run to switch ( using wago connectors)

3) will this work

Dave in AZ

Active member

1. Appliances... BlueSea fusebox is just for DC, 30A max each circuit, so I hope those are all dc appliances. Dont know what they would be. For me that is:Can you or someone elaborate maybe with a schematic … maybe,lol, no really, at this point hears where I’m about to be at,

1) I have wire running from appliances to two bluesea fuse boxes , one on each side of trailer ( wire is correctly sized):

2) for switches I’m using the nilight 6 gang on/off rocker type switches , cutting into the wire run to switch ( using wago connectors)

3) will this work

Led lights, 75w 6A

Maxxair fan, 36w 3A

Diesel heater, 110w 10A

Usb and cigar dc ports 120w 10A

All this is fed with an xt60 30A plug on 10AWG wire from my Pecron power station. Mine is 12 circuits, not sure why you need 2 BlueSea boxes, maybe 6 circuits?

2. Switches, that nilight 6 works fine. All my devices have their own on off switches, and I just pull the power station feed xt60 plug for master off.

3. Your setup sounds fine.

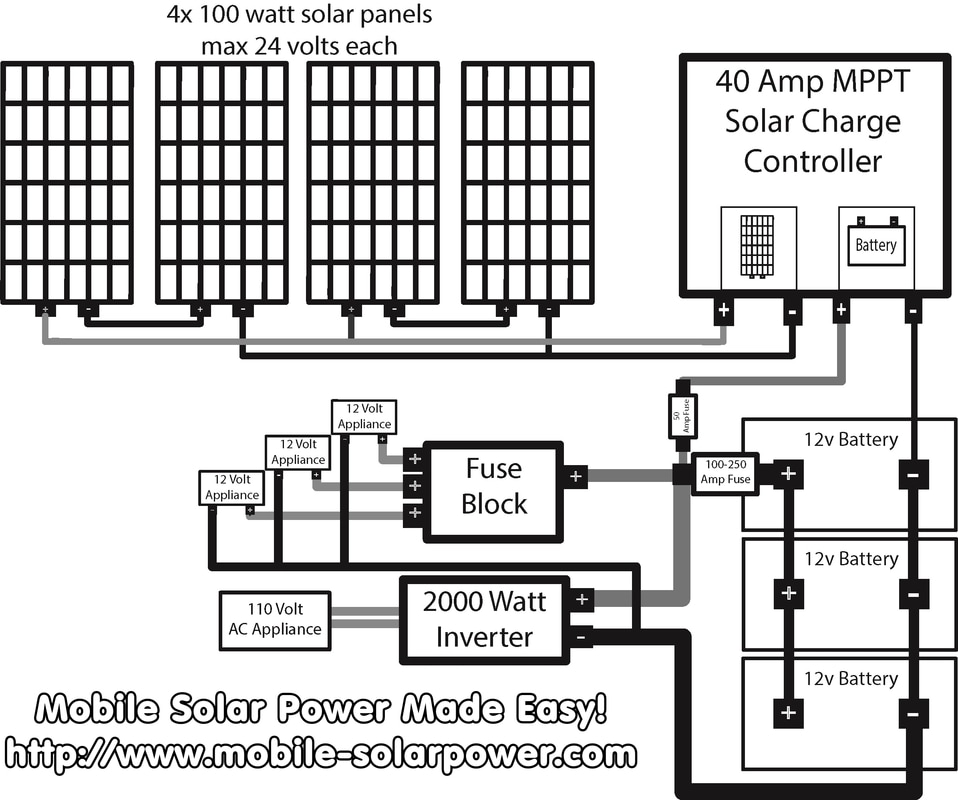

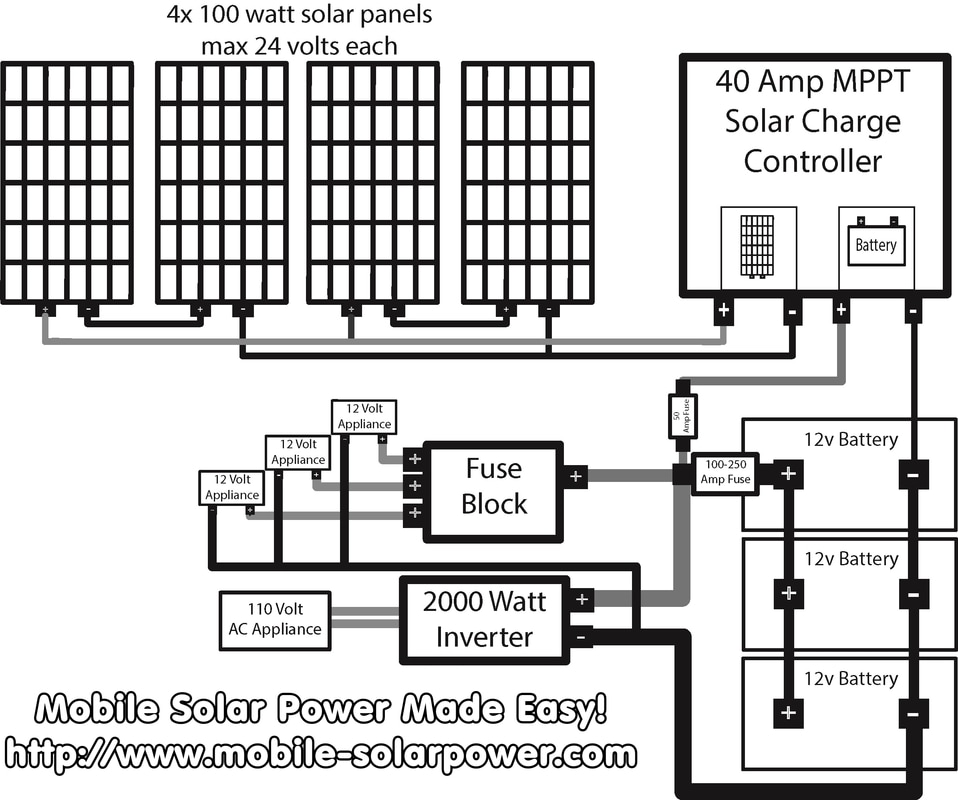

If you are using the lithium batteries, then review this setup for proper fusing on a battery system:

RV Solar Power Blue Prints

Building a vehicle mounted solar power system? Let me help.

www.mobile-solarpower.com

Yes all DC ,pretty much the same ,maxxair,5 kw diesel heater,LED puc lights, 12v. Valves on grey water tanks,usb , outside strip lights,refer cooler ect, two 6 circuit bluesea boxes , thanks again Dave in AZ1. Appliances... BlueSea fusebox is just for DC, 30A max each circuit, so I hope those are all dc appliances. Dont know what they would be. For me that is:

Led lights, 75w 6A

Maxxair fan, 36w 3A

Diesel heater, 110w 10A

Usb and cigar dc ports 120w 10A

All this is fed with an xt60 30A plug on 10AWG wire from my Pecron power station. Mine is 12 circuits, not sure why you need 2 BlueSea boxes, maybe 6 circuits?

2. Switches, that nilight 6 works fine. All my devices have their own on off switches, and I just pull the power station feed xt60 plug for master off.

3. Your setup sounds fine.

If you are using the lithium batteries, then review this setup for proper fusing on a battery system:

RV Solar Power Blue Prints

Building a vehicle mounted solar power system? Let me help.www.mobile-solarpower.com

Hey DaveinDenver, if you care to ,could you simplify even further ( haha) on your comments ,kinda scared meThere are reasons and even advantages (in the case of electronic switches it's basically mandatory to do low side practically) to switching the returns (negative) on loads but be aware that there is a safety aspect.

When you break the return side of a circuit what is left is a hot side just waiting to be shorted and you've surrounded it with a lot of chassis and body that is that path.

If you put the switch on that side don't also move the fuse or breaker to the return, either deliberately or unintentionally.

Dave in AZ

Active member

Nothing to worry about there. He was just pointing out that you can out a switch on a circuit anywhere on the wire to break the circuit--either before the load, on the positive or hot wire, or after the load on the return ground wire. Either spot breaks circuit.Hey DaveinDenver, if you care to ,could you simplify even further ( haha) on your comments ,kinda scared me

The point he was making is that if you run a bunch of lights in a row on the same circuit, if you switch the 1st light completely off on the positive then electricity doesnt flow to the other lights to be controlled separately. The answer is to not run them in SERIES, where the negative from one feeds into next positive, but in parallel. Better for correct voltages to LEDs anyways. Then your main feed wire goes around the camper, and you just split off some power from it to each light unit, and switch it separately. It's kind of a basic idea.

The other point someone made is that if you switch the negative side of a load then there is still power being applied to the positive wire and load, just not flowing. This gives more opportunity for a broken wire insulation or short circuit in a load to then pull power again. In general it is best to switch the positive side of circuit, and do it near power source if convenient, to depower wires. This is good practice in things that move and rub and could wear on wire insulation like a camper. But in this specific example, just wore the LEDs in parallel and switch each one if desired--mine all come with their own switch button.

I have a Chinese 5kw heater and need to run a 15 amp fuse for it. Finding a cheap 15 amp/DC switch is tough. I ended up using a Harbor Freight battery disconnect as a low cost solution. There is a primitive key that is used to operate the switch that will make you stop and think (hopefully) about if the heater is cooled down and safely to shut off the power.

Not sure about original posters design intent, but here is the schematic to my battery box. I have no charging ability on board the vehicle. My battery is big enough, and loads small enough, that I don't need to charge while mobile. No onboard charging is also good protection against charging at LiFePo4 at too low a temperature.

Note that the Columb counter is on its own switch and fuse so that the master switch to the loads can but shut off but the charging connecter and leads are still connected.

SW1 in the schematic is the second Harbor Freight Battery disconnect. One is the master switch for the battery box, the other is attached to the vehicle and is the heater disconnect.

The battery box has the electrical components integrated. I also used one of those Harbor Freight disconnects for the master battery shutoff as shown below

Note the spare 'disconnect key', screwed inside the bottom of the box, just in case the primary key goes missing.

Used Chinese Anderson Connectors on flying leads to connect heater and Ham radio. Third set of leads is for charger connection. I thought the panel mounted Anderson connectors were too pricey, and was concerned about the connectors taking a hit and getting smashed when rigidly conected to the battery box.

Not sure about original posters design intent, but here is the schematic to my battery box. I have no charging ability on board the vehicle. My battery is big enough, and loads small enough, that I don't need to charge while mobile. No onboard charging is also good protection against charging at LiFePo4 at too low a temperature.

Note that the Columb counter is on its own switch and fuse so that the master switch to the loads can but shut off but the charging connecter and leads are still connected.

SW1 in the schematic is the second Harbor Freight Battery disconnect. One is the master switch for the battery box, the other is attached to the vehicle and is the heater disconnect.

The battery box has the electrical components integrated. I also used one of those Harbor Freight disconnects for the master battery shutoff as shown below

Note the spare 'disconnect key', screwed inside the bottom of the box, just in case the primary key goes missing.

Used Chinese Anderson Connectors on flying leads to connect heater and Ham radio. Third set of leads is for charger connection. I thought the panel mounted Anderson connectors were too pricey, and was concerned about the connectors taking a hit and getting smashed when rigidly conected to the battery box.

Nothing to worry about there. He was just pointing out that you can out a switch on a circuit anywhere on the wire to break the circuit--either before the load, on the positive or hot wire, or after the load on the return ground wire. Either spot breaks circuit.

The point he was making is that if you run a bunch of lights in a row on the same circuit, if you switch the 1st light completely off on the positive then electricity doesnt flow to the other lights to be controlled separately. The answer is to not run them in SERIES, where the negative from one feeds into next positive, but in parallel. Better for correct voltages to LEDs anyways. Then your main feed wire goes around the camper, and you just split off some power from it to each light unit, and switch it separately. It's kind of a basic idea.

The other point someone made is that if you switch the negative side of a load then there is still power being applied to the positive wire and load, just not flowing. This gives more opportunity for a broken wire insulation or short circuit in a load to then pull power again. In general it is best to switch the positive side of circuit, and do it near power source if convenient, to depower wires. This is good practice in things that move and rub and could wear on wire insulation like a camper. But in this specific example, just wore the LEDs in parallel and switch each one if desired--mine all come with their own switch button.

Yea researching solar I got the series and parallel concept down , I have a couple clusters of LED pucks that will be on separate switches and parallel , I just did a bunch of reading on switching and loads now that’s making sense what Dave in Denver was saying, thanks for clarifying an getting me on the right track

Forum statistics

Members online

- RJWB

- TheBestCow

- KelliT

- mark5280

- Drewdaman

- Flashbangg

- ITTOG

- COrider

- Boulder Cruiser

- Ozarker

- 1979ford

- ErWinB

- 1RagingApe

- Mtaco3

- sancap

- Korey H

- asafk

- Profsmallpine

- Walker Evans

- Thestraycat

- Kingsize24

- Zeep

- Rockymountainhunter

- Velobrew

- jeepers29

- Mojavejohn

- jgaz

- Burley

- Avihay

- cpancho

- frank84

- apinajus

- tractor_to_trail

- jarekben

- Spencer for Hire

- Doslocos

- en480c4

- DarioCarrera

- Mickey Bitsko

- Gravity

- Starfire

- bigsam

- zip

- Danchi007

- jmt82331

- Robbus

- CoryQuackenbush

- bstock1

- Savagenut

- Broshaker

Total: 911 (members: 54, guests: 857)