Okay, so long overdue, here's how it all got wired. Be forewarned, this wiring job is definitely not the cleanest, and it's not entirely permanent. Due to the amount of electrical accessories being put on the truck, I will be adding a completely separate fuse box to make wiring cleaner and easier. That will probably go in the cab, under a seat or something. Still looking into possible solutions.

So! The install!

I hadn't planned on doing this all at once and by myself, but that's how it ended up. I started by bolting on the relays and running the ground and power wires. The relays I have have four terminals, marked 30, 85, 86, and 87. I attached ground wires roughly 8" long to the 85 terminal at one end and to a sheet metal screw in the engine bay at the other. I made power wires, complete with inline fuses, and ran them from the 30 terminal to the positive terminal on the battery.

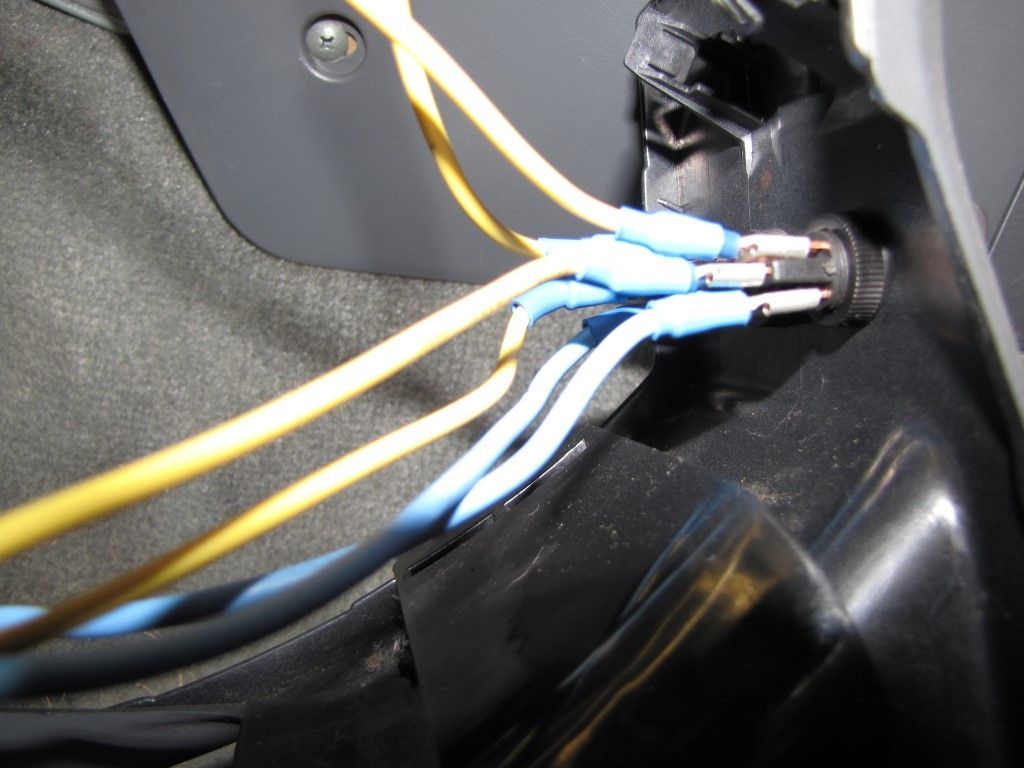

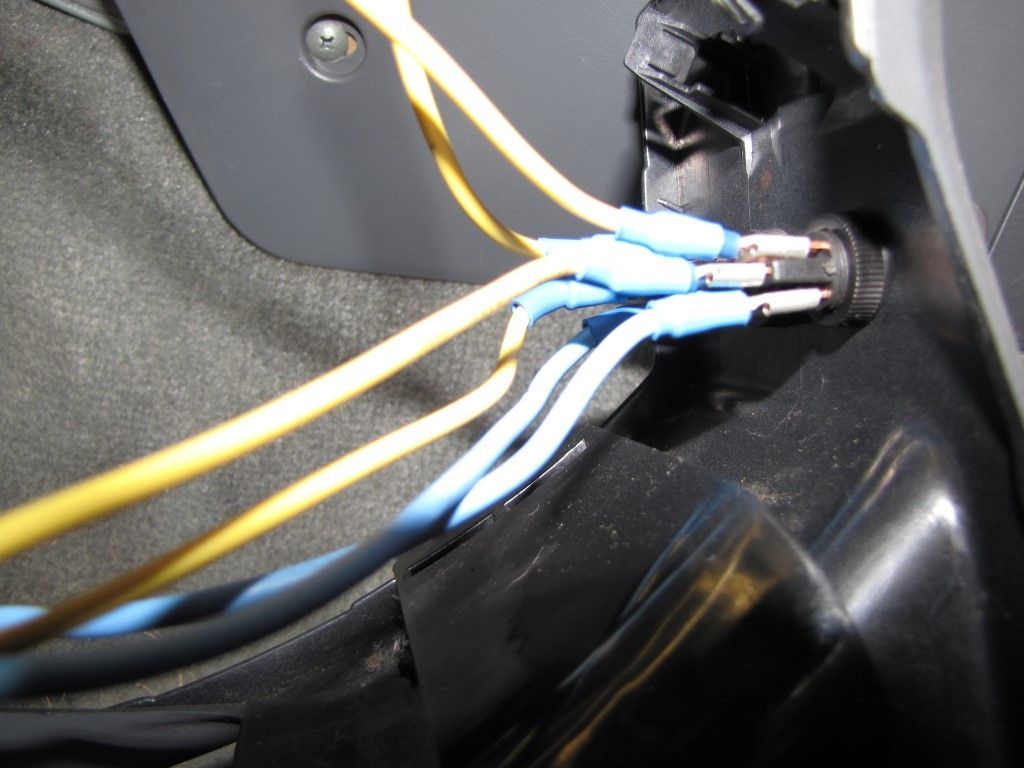

At this point, I figured I had gotten this far, so I might as well build wires for the switches. I measured out the amount I'd need by running it from the 86 terminal to the switch via whatever path I wanted. I decided to simplify for now by not running them through a grommet in the firewall, but by going through the door jam. I know this isn't the cleanest or the best way to do it, but as I said, this is only temporary. It will all get cleaned up once I put the accessory fuse box in place.

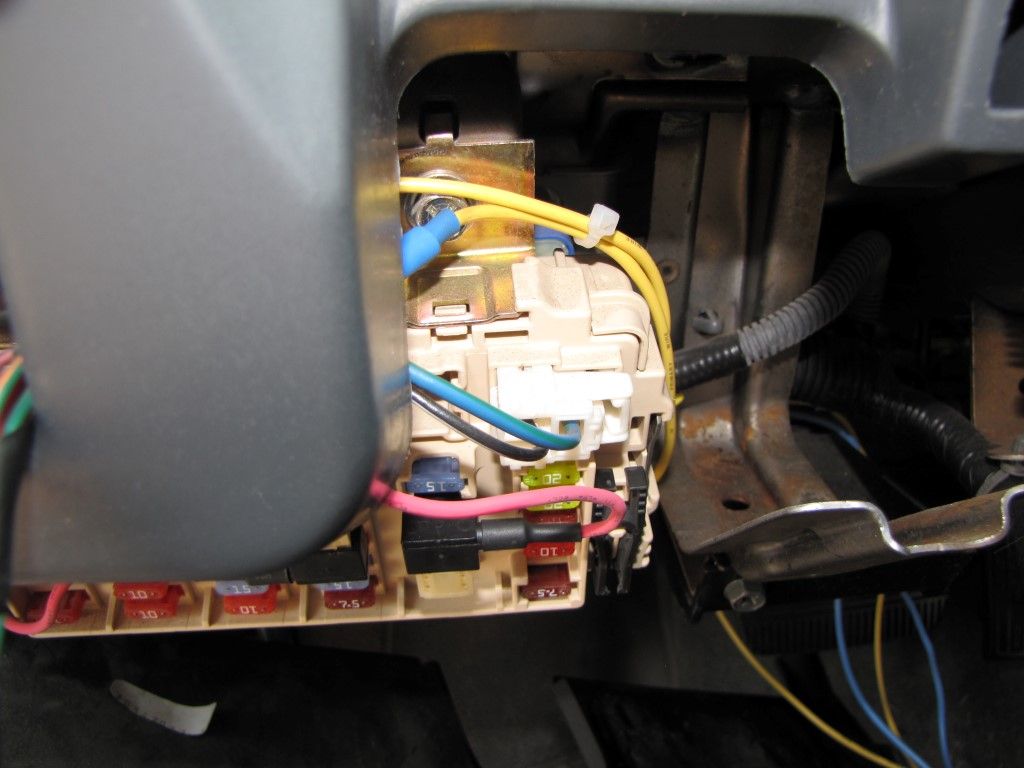

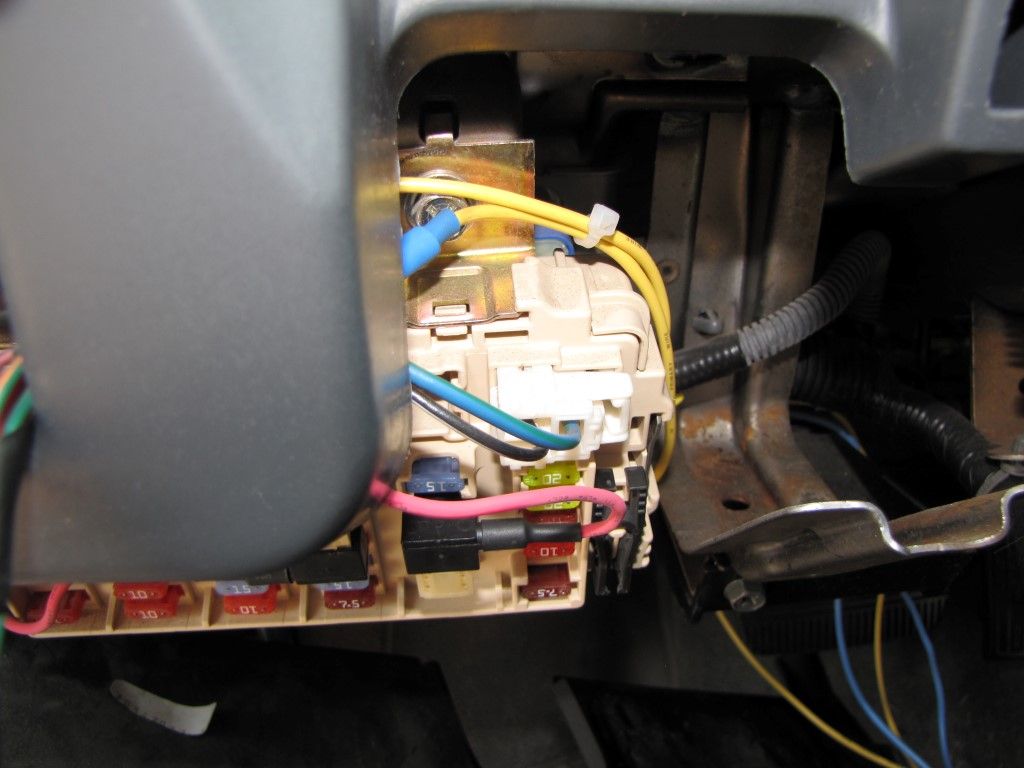

I was now far enough along that I figured I might as well buy and wire in the switches. After a $25 trip to O'Reilly, I drilled the holes into the dash where I wanted the switches to go (and two where I couldn't put them. Oops!) After installing them, I hooked up the wires from the relays to the switches. I had come this far, so I thought I might as well wire them up the rest of the way. I ran fuse taps from each switch to the fuse box, and then I grounded each switch to a bracket behind the dash panel.

After that, I was nearly done! I had enough wire left over to build wires that would run to the lights, so all I had to do was wait for the Xoskel bar to show up.

After getting it and having to mess with it, I have some mixed feelings about the Xoskel light bar. Looking at it, you know it is a very well made product, with all the fit and finish. Good welds, nice coating, all that. But the design is a bit strange. The first problem I ran into was that the mounting holes for the lights were a bit small, so I had to drill them out. The bar mounts to the factory crew cab roof rack via the forwardmost factory bolt holes. There are only two bolts holding the whole thing in place, which strikes me as a bit underbuilt. Also, I don't know if there are variances here, but the light bar I got had holes that were 1/4" closer together than the factory mounting holes, which means I had to loosely screw one side in, then pull on the bar while I wrestled the other bolt into place. The idea of the light bar is to sit low to the roofline and be low profile, but this does present some problems. Primarily, the bar sits so close to the roof that the mounting bolts on your lights, whatever they may be, will likely be too long and actually hit the roof of the truck. So, the bolts must be either cut or replaced with ones that are short enough. The other issue with the low profile design, as well as the fact that it is only mounted with two bolts, is that once you add the lights, and therefore, weight, to the bar, it sags and comes into contact with the roof. I was able to fix this with narrow foam rubber tape between the bar and the roof. Once I got these little hiccups worked out, I was able to get to the wiring.

Wiring the lights got a bit fiddly. The idea was to eliminate the need for a ground wire by grounding the lights to the bar and then using the bolts to ground the bar to the truck. Turns out it doesn't work that way, though I'm not entirely sure why. What I ended up doing was soldering the ground wire of each light to a washer that I would put on each light's mounting bolt. This made the wiring look pretty clean. For the power wires, I ran a wire up from the 87 terminal of each relay, through the engine bay, and up through the door seal to the back of the light bar. Again, not the cleanest, but this particular method suits me just fine. Then each wire splits into two power wires, one for each light. Once I was here, I stopped, disassembled everything, and covered most of it with electrical tape to make it cleaner.

Once I had everything back together and in place, I tried the lights. They didn't work. I decided it was probably a bad ground, and so I made a jumper wire to test it. I connected one end to a body panel bolt, and the other to the light bar bolt. Worked like a charm. So, to fix the problem, I built a 10 gauge ground wire and ran one end to a body panel bolt, and the other one to the light bar bolt. I taped everything up, and I was done! All I had to do was aim the lights.

So there it is! I'm very happy with the way everything turned out. I think the end result looks great. The lights work really well too, the only downside is glare you get from the hood and windshield. While this is prevalent, the visibility is still better with the lights on than off.