rustED

Adventurer

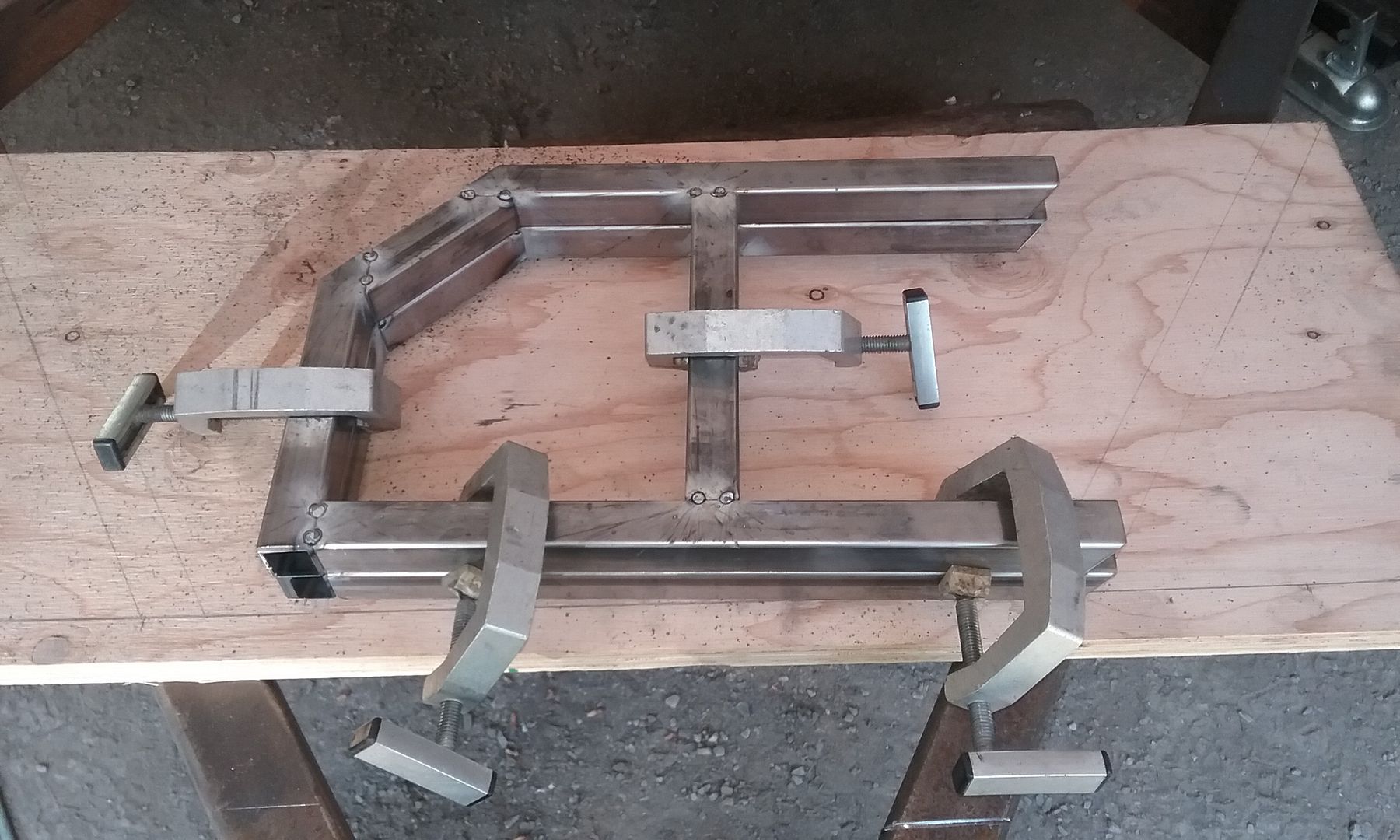

^^^I finished one side step, and got the second tacked welded together, I was pretty happy with my clamping method, the second step turned out a near perfect match...that's when I realized I needed to make it a mirror image for the opposite side so my 30° cuts where the steps meet the fenders are on the wrongs side..DOH! Luckily it's only tacked together, one of the peices I can flip over then re-weld, the other had a 45° angle cut on one end and a 30° on the other, so I'look have to recut that peice...always seems like one step forward and two steps back.

Here's a pic of the passenger step in place.

It didn't take long to burn through 80 feet of 1" square tubing, I have just enough to fix the driverside step and add some braces between the stringers on the lid to tie it all together and make it all little stronger.

Last edited: