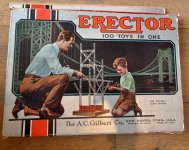

After much hate. Just think a trailer that will last 100s of years. Don't even need to own a tape . Easyer to build with just a marking stick . .Don't even need to cut a straight line, can be up to a 1/2'' to short on the exterior skeleton. As the hand laid fiberglass with woven / foam . can be cut up to 11/4 '' to short . The panel floats in the hand laid fiberglass with woven exterior skeleton.. Can you believe some of the not planning ahead are low lifes that want your trailer to fall apart in 10 years or so, using aluminum angle. Because of differences in expansion rates. Goes together like a Erector set like you may have built when you were younger.

The hold up on posting was father-in-law trying an even easier way to build . . done a few posts on FB. got hate .

Can you answer me this ? Why would anyone build a trailer that can fall apart in 10 years? the main thing I see at the shops is older people get these crap trailers that fall apart . The older you get, the more it hurts to maintain are fix . The glue and go style of trailers. You go to Walmart to get what you need to fix, and no $250 book rate per hour at a shop.The person who builds these for us is 70 with one good arm . The last picture is so easy to build cap with no mold . Just 3 layers of 2'' straps of fiberglass . That you sand to look good . You start with 3 layers of clear packing tape on the pod so you can remove and have space for sealing

Can you find the sidecar for two in the picture?

www.youtube.com

www.youtube.com