You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1959 GMC Adventure Bus Build

- Thread starter baipin

- Start date

baipin

Active member

Thanks for the nice words about the project, guys. I appreciate it.

I haven't had much of a chance to work on the bus. Work keeps me busy. However, i did have a chance to weld up a battery fixture for the LiFePO4 cells. This will maintain some light compression on them which increases lifespan:

The top lip will help secure a piece of plexiglass over the terminals and provision BMS mounts:

Far as wheels and tires go; I may exchange my current Humvee 37's for something with a bit more load capacity. I bought them from a local business (militarytires.ca) and the owner said I could exchange them for a different set of tires if they didn't work for my build. 325/85R16's would be the ideal size I think, but they only have XML's in that size and I suspect they'd be horrible for fuel economy/tread life. I don't even know of another Canadian source for Conti MPT81's, XZLs, etc. in that size. Shipping from the US is prohibitively expensive, especially with the exchange rate.

What I am considering doing is buying a new rear end - something from a bus, Ford F700, etc. - and running 43" 11R20 XZL's. This will allow me to carry plenty of weight in the rear, easily two tons more than what I had intended, which is really nice headroom to have. I can get plenty of those for cheap, all around the country, since our military's logistic trucks run them - so there's a steady supply. at home and on the road. The one problem with this is the Dana 60 front axle. Will 35 spline stuff hold up? Are stock brakes (albeit with a Bosch Hydromax booster) okay? I'll be adding a Jantz load bolt to mitigate ring gear deflection. It's not as if I'll be rock crawling the bus, but I also don't want to overextend the axle's abilities.

If I used an aluminum 20" dually wheel on the front axle, I could get the total weight of a 43" XZL tire/wheel down to 180lbs. By comparison, my 37" Humvee tires/wheels are 150lbs. Is a 6" and 30lb difference enough to cause serious problems?

Here's a mockup with an 8" roof raise, and 37" vs 43" tires (yeah, the 43" should be XZL's, I was too lazy to photoshop those in)

43":

37":

I haven't had much of a chance to work on the bus. Work keeps me busy. However, i did have a chance to weld up a battery fixture for the LiFePO4 cells. This will maintain some light compression on them which increases lifespan:

The top lip will help secure a piece of plexiglass over the terminals and provision BMS mounts:

Far as wheels and tires go; I may exchange my current Humvee 37's for something with a bit more load capacity. I bought them from a local business (militarytires.ca) and the owner said I could exchange them for a different set of tires if they didn't work for my build. 325/85R16's would be the ideal size I think, but they only have XML's in that size and I suspect they'd be horrible for fuel economy/tread life. I don't even know of another Canadian source for Conti MPT81's, XZLs, etc. in that size. Shipping from the US is prohibitively expensive, especially with the exchange rate.

What I am considering doing is buying a new rear end - something from a bus, Ford F700, etc. - and running 43" 11R20 XZL's. This will allow me to carry plenty of weight in the rear, easily two tons more than what I had intended, which is really nice headroom to have. I can get plenty of those for cheap, all around the country, since our military's logistic trucks run them - so there's a steady supply. at home and on the road. The one problem with this is the Dana 60 front axle. Will 35 spline stuff hold up? Are stock brakes (albeit with a Bosch Hydromax booster) okay? I'll be adding a Jantz load bolt to mitigate ring gear deflection. It's not as if I'll be rock crawling the bus, but I also don't want to overextend the axle's abilities.

If I used an aluminum 20" dually wheel on the front axle, I could get the total weight of a 43" XZL tire/wheel down to 180lbs. By comparison, my 37" Humvee tires/wheels are 150lbs. Is a 6" and 30lb difference enough to cause serious problems?

Here's a mockup with an 8" roof raise, and 37" vs 43" tires (yeah, the 43" should be XZL's, I was too lazy to photoshop those in)

43":

37":

Attachments

I like the look of the larger wheels - good call on raising the roof, school busses always seem too short on the ceiling. Also, the silver engine paint looks cool - like a prototype from a machine shop! What are your thoughts for final colors/paint? If you can find 41" 335/80r20s, they might be easier to fit than the 43s. I've been watching colony tire on ebay.

baipin

Active member

I like the look of the larger wheels - good call on raising the roof, school busses always seem too short on the ceiling. Also, the silver engine paint looks cool - like a prototype from a machine shop! What are your thoughts for final colors/paint? If you can find 41" 335/80r20s, they might be easier to fit than the 43s. I've been watching colony tire on ebay.

Yeah, the larger wheels do look better, have more capacity, 43" XZL's should be fine for the D60 axle with the uprades, and they prevent me from having to regear the front axle - which is a nice bonus. Colony Tire has great stuff though I'm at the behest of whatever I can exchange with militarytires.ca's stock, or find a way to sell these tires to a third party. Unlikely. I have been chatting with the militarytires.ca guy; he confirmed I can trade in my Humvee tires for whatever I want.

Problem is; the only tires he has in the 11R20 XZL size are freakin' old - 2001 date codes. Our military does not use them anymore so the surplus market has dried up. He does have G177's which are 44" tall and with lightweight aluminum wheels come in at 190lbs.30lbs heavier than the XZL combo and 1" taller. I believe those are 2014 and 2015 date codes. Seems fine? Scared of pushing it with tire size and weight though...

Don't worry about the tires not fitting on the rear; the wheel well actually is - to my surprise - a fair bit larger than the skirt's cutout suggests. Probably because this bus body, in longer varieties, ran 9R20 and 10R20 tires back in the day.

My current options:

- 335/80R20 XL: https://militarytires.ca/product/12-5r20-michelin-xl-on-wheel/ This size would be wonderful, though I can only find them in a XL pattern. I feel like that's going to be a noisy, fuel-inefficient mess with low tread life though. But I could be wrong. Any thoughts on the XL vs G177 vs XZL vs BFG Baja for tread life and fuel efficiency? I could run these on the rear with 5 ton wheels in a 10x11.25 bolt pattern, which is cool. https://militarytires.ca/product/20x10-titan-5-ton-wheel/ Would bolt right up to any "big rig" rear axle. Problem is, I think they're MPT beads which means finding a lightweight aluminum wheel for the front axle is difficult. This would work: https://militarytires.ca/product/20x10-hutchinson-mrap/ but total weight is around 215lbs. That's probably too much for even a 35 spline Dana 60, right? Only 40" diameter, however.

- 11.00R20 G177: https://militarytires.ca/product/11-00r20-goodyear-g177/ Pushing it with weight (190lbs including aluminum wheel) and size (44") but doable, I think. Unsure if 20x8.5 beadlock will fit these, for the rear axle. He has more than listed on the website, with 2013 and 2014 date codes. If I'm swapping tires this is probably the best option.

- 325/85R16 XML: https://militarytires.ca/product/325-85r16-michelin-xml/ I don't see the advantage over what I currently have. They're like an inch taller, half an inch wider, only 540lbs more load per tire, the tread would be way worse on the road, and II only gain 1080lbs more capacity on the rear which doesn't significantly change things in my opinion, especially considering the pitfalls.

- Keep the Humvee tires: Given weight calculations on the previous page, I should be fine given my target while still retaining 10%-18% additional tire capacity. Not sure all this trouble is worth it.

Those Michelin XL's look like the Pirelli PS22.

Some threads I've looked at when considering these:

expeditionportal.com

They seem to have a narrow tread relative to other similar tires - something like 8" wide compared the expected 11-13" width at the ground. I was thinking this might be helpful for steering linkage clearances at full lock-out, and may actually help fuel economy with the smaller contact patch. Haven't found a good estimate on lifespan on these & I don't have personal experience with any of these.

expeditionportal.com

They seem to have a narrow tread relative to other similar tires - something like 8" wide compared the expected 11-13" width at the ground. I was thinking this might be helpful for steering linkage clearances at full lock-out, and may actually help fuel economy with the smaller contact patch. Haven't found a good estimate on lifespan on these & I don't have personal experience with any of these.

Some threads I've looked at when considering these:

Opinions on Pirelli Pista?

Can anyone comment on the Pirelli Pista tires? I am looking at 335/80 R20 specifically. I was weighing them against the Goodyear G275. The pirelli appears to be narrower in the tread, though without having them side by side, I have only the numbers to go on. The truck they will be installed on...

expeditionportal.com

expeditionportal.com

baipin

Active member

Those Michelin XL's look like the Pirelli PS22.

Some threads I've looked at when considering these:

They seem to have a narrow tread relative to other similar tires - something like 8" wide compared the expected 11-13" width at the ground. I was thinking this might be helpful for steering linkage clearances at full lock-out, and may actually help fuel economy with the smaller contact patch. Haven't found a good estimate on lifespan on these & I don't have personal experience with any of these.

They seem to have a narrow tread relative to other similar tires - something like 8" wide compared the expected 11-13" width at the ground. I was thinking this might be helpful for steering linkage clearances at full lock-out, and may actually help fuel economy with the smaller contact patch. Haven't found a good estimate on lifespan on these & I don't have personal experience with any of these.

Opinions on Pirelli Pista?

Can anyone comment on the Pirelli Pista tires? I am looking at 335/80 R20 specifically. I was weighing them against the Goodyear G275. The pirelli appears to be narrower in the tread, though without having them side by side, I have only the numbers to go on. The truck they will be installed on...expeditionportal.com

Thanks for this. The Pistas are interesting, just can't find them up here very often.

XL's are out. I just checked and the 12.50R20 variety actually have 170lbs less capacity per tire than my current H1's. Yet again the H1's seem to be the best well-rounded bet, all things considered. Worst case scenario with the H1's is a run them as duals; stock 16.5x6.75 dually rims with a 3" steel spacer in between is a proven setup on and off-road. BSF Towing on youtube uses this setup.

Any thoughts on running 22.5" commercial truck tires? I've received very polarizing responses on those. My main issue there is the lack of a beadlock or two-part rim options; I worry about changing a flat tire myself if I have to, with a single-piece rim/tire that large and heavy.

baipin

Active member

Been busy with the holidays, and fabricating bits and pieces for this bus. Nothing major to show yet, but here's what we have for now:

I finished up the truss on my front axle... the gussets for the inner C's were refined a bit, and a stainless strip was added a month ago, to the bottom to, act as a wear surface should it hit anything. With all the salt on our roads, I'll do what I can to reduce chances of paint getting scraped off and causing rust. It also looks nice!

I also fabbed up this massive heim/mounting bracket for a hydraulic cylinder...

So now we'll have hydraulic assist steering! The powerful 2"x8" cylinder will be driven by a relatively high GPM power steering pump that comes on the DT360.

Still not sure if I'll go a loadbolt on this axle, or swap it to Dana 70 gears... which would cost $800 or so. I'm not sure if that's the most reasonable use of money though. Having chatted with OKA owners - whose rigs use a Dana 60 kingpin like mine, and weigh about the same as my bus - maybe a touch lighter overall, but with a very close front axle weight; the Dana 60 seems sufficient even with less upgrades than what I have (truss, gussets, 35 spline outers, a load bolt at minimum, if not a load bolt + 70 gears).

I finished up the truss on my front axle... the gussets for the inner C's were refined a bit, and a stainless strip was added a month ago, to the bottom to, act as a wear surface should it hit anything. With all the salt on our roads, I'll do what I can to reduce chances of paint getting scraped off and causing rust. It also looks nice!

I also fabbed up this massive heim/mounting bracket for a hydraulic cylinder...

So now we'll have hydraulic assist steering! The powerful 2"x8" cylinder will be driven by a relatively high GPM power steering pump that comes on the DT360.

Still not sure if I'll go a loadbolt on this axle, or swap it to Dana 70 gears... which would cost $800 or so. I'm not sure if that's the most reasonable use of money though. Having chatted with OKA owners - whose rigs use a Dana 60 kingpin like mine, and weigh about the same as my bus - maybe a touch lighter overall, but with a very close front axle weight; the Dana 60 seems sufficient even with less upgrades than what I have (truss, gussets, 35 spline outers, a load bolt at minimum, if not a load bolt + 70 gears).

My mouth dropped open after getting half way through your first post! ?

That reminds me of my first school bus ride.

How'd you learn so much about these mechanical aspects at your age?

I think you'd make a great high school shop teacher!

All the best with this incredible build!

That reminds me of my first school bus ride.

How'd you learn so much about these mechanical aspects at your age?

I think you'd make a great high school shop teacher!

All the best with this incredible build!

baipin

Active member

My mouth dropped open after getting half way through your first post! ?

That reminds me of my first school bus ride.

How'd you learn so much about these mechanical aspects at your age?

I think you'd make a great high school shop teacher!

All the best with this incredible build!

Thanks man - I appreciate all of that!

Interesting story how I got started with all this, actually... My grandfather was a cobbler and fabricator in a small town in Ukraine, then moved to Alberta, then Ontario, where I grew up. He did the same job all his life - over there and over here. Spent a lot of time in his shop as a kid and loved it.

From 18 to 20, I went to an art and industrial design school. Our sculpture teacher was a retired welder, he taught me MIG, which I enjoyed - you can build anything by zapping some metal until it melts

Would be nice to become a shop teacher - it's been a goal in the back of mind for ages!

I play outside

Member

I love this build. Many builds are slow and lots of talk. Your dumping hours into this thing and showing it in like 5 pics. This thing is rad man. Love the ”im just gonna build this….” Approach. It’s clear you think things out. But you don’t get bogged in over analyzing stuff. props on the fab skills.

baipin

Active member

Awesome build. That is a ton of work! Be careful with the 335/80/20 tires and surplus 20” military wheels. Most are made for the bead of a 365 tire. I had to cut 2” off the outside diameter of my mrap wheels to get the tire bead to seat properly.View attachment 760555

Damn, a whole inch eh?! Wouldn't have thought it'd be that much. I've been following your build - I'm a fan of it! I was under the impression that all MPT wheels bead profiles were the same, regardless of if 335's or 365's were going on. Guess not eh?

Given the inability to source new date code surplus tires up here, or find new ones easily, let alone for a reasonable price... One thought did occur to me: Overseas Chinese/Taiwanese tires. I was initially leery, but they are DOT rated of course, and a massive share of the big rigs run them here. It's one of the few ways I could easily source 20" tires (e.g. Annaite 339) in Canada. Practically speaking; the alternatives are running 22.5's, running 20" surplus Michelins or Continentals with a year or two left on the date code, or just sticking with my Humvee tires and the weight restrictions inherent to running them as singles (I could hypothetically dual them - I wouldn't be the first).

@baipin - This is one ambitious project! Love what you're doing and look forward to seeing it on our Ontario roads one day.

Thank you - looking forward to seeing you around!

I love this build. Many builds are slow and lots of talk. Your dumping hours into this thing and showing it in like 5 pics. This thing is rad man. Love the ”im just gonna build this….” Approach. It’s clear you think things out. But you don’t get bogged in over analyzing stuff. props on the fab skills.

Thanks dude! It's damn laborious, but I wouldn't trade it for anything. I'm one to ge distracted easily... so the less talk, the less pics, the more "actually getting stuff done" the better haha.

---

Some other fun stuff:

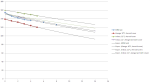

Any of you who've spent time in the catering industry or in convention centers might know what these are... Vacuum-insulated beverage and soup canisters, basically. I bought one for a hundred bucks, similar to the one in the photo. Given they're vacuum-insulated, they're about as thermally efficient as you could feasibly get in a small package - 5 gallons in my case. I've since adapted the spigot to accept NPT fittings, and the lid will be modified to accept a thermocouple, water inlet, and heating element. I ran some experiments testing the efficiency, and it did pretty damn well:

Sorry in advance for mixing units lol... Basically; the red plot is the worst-case scenario; the Aervoid was kept in a cold garage, on the concrete floor but with an insulated pad beneath it. It "kept temperature" (140°F to 120°F, 20°F drop) for 5 hours.

Aervoid's own benchmark test was for 6 hours; that's the blue plot.

Indoors, 22°C, on the same insulated pad as used before with an inferior lid made of just a bath towel and a piece of aerogel fabric (meant to simulate a moderately insulated DIY lid that isn't vacuum insulated but has provisions for a heater element, water inlet, temp probe, etc); temperature was retained for about 7 hours. This is the purple plot.

Indoors, 22°C, on the same insulated pad as used before, and with the vacuum-insulated lid; temperature dropped 20°F over 8.5 hours. This is the green plot.

The idea is that once water is heated, it can stay heated throughout the day, and I can have a small albeit constant source of hot water in the bus. More importantly; this is efficient enough that I could heat water purely off of solar if I really want to. Assuming I could retain heat for 8 hours with a custom lid that falls between the best two cases in terms of efficiency: It takes 12.35 watts to raise my 5 gallon water tank by 1 degree in 1 hour. To raise it 20°F, that's 247Wh of energy, expended every 8 hours, or 741Wh each day to keep the water warm. Assuming 800Wh for inefficiencies; that's 10% of my daily insolation assuming 8kWh are generated by a 2kWh panel array each day. Or, 6% of my total battery bank. In the winter, I'd be using a wood stove and/or diesel heater to keep warm, so insolation then is less of a concern as waste heat would be directed to the hot water tank (e.g. scavenged off of exhaust).

charlieaarons

Explorer

335/80 and 365/80 R20 both are MPTs, and use the Hutchinson 11” wheels (some 335s can use a 9” wide MPT wheel). 365/85R20 and larger are supposed to be mounted on the 10” wide wheels. I don’t know the precise difference in beads but I do know from looking at ALL the tire specs and Hutchinson’s data that they shouldn’t be mixed.

I am sure some “have gotten away with it”. Not a wise practice with heavy vehicles, especially if low pressure running offroad is contemplated.

Maybe, when jds made the penultimate post, when he said “365” he meant 365/85/R20. It seems baipin interpreted it as 365/80R20.

I am sure some “have gotten away with it”. Not a wise practice with heavy vehicles, especially if low pressure running offroad is contemplated.

Maybe, when jds made the penultimate post, when he said “365” he meant 365/85/R20. It seems baipin interpreted it as 365/80R20.

baipin

Active member

Not much to show for right now. I received some offers to teach up north, which is exciting - gives me some justification for taking the bus on the ice roads up in northwestern in Ontario - and for the R24 to R30 insulation I'm planning on.

I've completed more accurate weight calculations. This includes the heaviest interior conversion I could imagine given the space, the most spare parts and tools, and the most people I'd plan on carrying. Technically the weight capacity of these tires is 9,080lbs, but I do not wish to run them at capacity. So, with 10% overhead (8,172 lb max), I get a 700lb remaining payload weight. I can't imagine I'd ever touch that, as the current estimate accounts for people, food, clothes, water, fuel, cabinetry, insulation, floors, bicycles, spare tires, spare parts, electrical components, plumbing, solar panels, batteries, furniture, etc. with a 2,900lb weight. I suspect it'd be closer to 2,600lb.

Important to note that putting tools, straps, jacks, etc. in a box on the front bumper, would help alleviate weight over the rear. Even just 100-200lbs worth. There's a 28"x6"x8" pocket behind where the winch mounts, and in front of the radiator, that would be a great storage location provided I can find (or make) a box to fit.

What made the largest change, was moving the axle back 3.5". Better weight distribution, better departure angle to match the breakover.

Having higher capacity singles would be nice, but ones with a new enough date code are seemingly impossible to come by right now. It's either 37" Humvees, 44" XZLs, or 47" MV/T's which would be absurd on this size of bus. For the moment, I'll keep the Humvees and consider dualing them on the rear if I somehow really need the capacity.

I've completed more accurate weight calculations. This includes the heaviest interior conversion I could imagine given the space, the most spare parts and tools, and the most people I'd plan on carrying. Technically the weight capacity of these tires is 9,080lbs, but I do not wish to run them at capacity. So, with 10% overhead (8,172 lb max), I get a 700lb remaining payload weight. I can't imagine I'd ever touch that, as the current estimate accounts for people, food, clothes, water, fuel, cabinetry, insulation, floors, bicycles, spare tires, spare parts, electrical components, plumbing, solar panels, batteries, furniture, etc. with a 2,900lb weight. I suspect it'd be closer to 2,600lb.

Important to note that putting tools, straps, jacks, etc. in a box on the front bumper, would help alleviate weight over the rear. Even just 100-200lbs worth. There's a 28"x6"x8" pocket behind where the winch mounts, and in front of the radiator, that would be a great storage location provided I can find (or make) a box to fit.

What made the largest change, was moving the axle back 3.5". Better weight distribution, better departure angle to match the breakover.

Having higher capacity singles would be nice, but ones with a new enough date code are seemingly impossible to come by right now. It's either 37" Humvees, 44" XZLs, or 47" MV/T's which would be absurd on this size of bus. For the moment, I'll keep the Humvees and consider dualing them on the rear if I somehow really need the capacity.

Similar threads

- Replies

- 3

- Views

- 380

- Replies

- 1

- Views

- 773

- Replies

- 21

- Views

- 3K