Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1986 GMC S-15

- Thread starter Andrew_S

- Start date

My heart skipped a beat when you talked about hitting the deer. Obviously I'm glad your ok. In the moment I was thinking... NOOO not the end to the truck and this thread!!!! Glad your going to fix it. Going to try and get it all painted to match or just run patchwork style? Hope it doesn't take you to much work and you can get it back on the road soon and get back to adventuring!

1stDeuce

Explorer

Glad you're all OK! Too bad ARB doesn't make a bull bar for that truck. Perhaps one for an XJ or ZJ could be made to fit.

Tons of rust free parts down here in SW CO for that that thing. I spent an hour at my favorite yard Monday looking for a complete 2.8L 5-speed that I can pull the FI stuff off for the Comanche... Two there, but both missing the engine. I got a line on a '88 Blazer that has everything I need but the ECM, and I can get that from the yard no problem.

Have fun fixing it, and if we're voting, I vote you keep the classic look if you can find the parts.

Tons of rust free parts down here in SW CO for that that thing. I spent an hour at my favorite yard Monday looking for a complete 2.8L 5-speed that I can pull the FI stuff off for the Comanche... Two there, but both missing the engine. I got a line on a '88 Blazer that has everything I need but the ECM, and I can get that from the yard no problem.

Have fun fixing it, and if we're voting, I vote you keep the classic look if you can find the parts.

Last edited:

Bojak

Adventurer

Just damn. That's why I stack as many of them in the freezer as I can every season. I feel in this modern era with fewer hunters every year and too many hunters focused on trophies bucks that I am doing a Civic duty by harvesting a full limit. It's a big responsibility but I do it for all of us....lol

Sent from my Pixel 2 XL using Tapatalk

Sent from my Pixel 2 XL using Tapatalk

Andrew_S

Observer

No dice, i love the old three piece grills. Just wouldn't be the same truck with the one piece.The doe wants you to convert to a 91-94 grille ?

Wow! What a story. Sucks about hitting the deer, but you guys are fine as you said, and everything looks easily fixable. Might be time for a grill guard/brush bumper however.

Beautiful pictures aside from the smashed up truck. Could have been much worse, as you said. Agreed with the above post about perhaps adding a bumper.

Thanks guys, The ARB mj/xj bumper is something I've definitely been eyeing up lately.

Damn, bum luck with the doe! The important thing is you guys were not hurt, I've seen those puppies do some real damage. Any chance of a few upgrades while you have it apart? Just saying....

Just going to be making it a little more reliable if I can. Hoping to have it back on the road for hunting season (1 month away)

My heart skipped a beat when you talked about hitting the deer. Obviously I'm glad your ok. In the moment I was thinking... NOOO not the end to the truck and this thread!!!! Glad your going to fix it. Going to try and get it all painted to match or just run patchwork style? Hope it doesn't take you to much work and you can get it back on the road soon and get back to adventuring!

Hoping to get it all painted and basically returned to the way it was. Thanks for the encouragement!

Glad you're all OK! Too bad ARB doesn't make a bull bar for that truck. Perhaps one for an XJ or ZJ could be made to fit.

Tons of rust free parts down here in SW CO for that that thing. I spent an hour at my favorite yard Monday looking for a complete 2.8L 5-speed that I can pull the FI stuff off for the Comanche... Two there, but both missing the engine. I got a lone on a '88 Blazer that has everything I need but the ECM, and I can get that from the yard no problem.

Have fun fixing it, and if we're voting, I vote you keep the classic look if you can find the parts.

You read my mind. I've been looking at the MJ/XJ front bumper but I'm undecided at the moment. Definitely keeping the classic 3 piece grill. Good luck on the Fuel injection conversion!

Just damn. That's why I stack as many of them in the freezer as I can every season. I feel in this modern era with fewer hunters every year and too many hunters focused on trophies bucks that I am doing a Civic duty by harvesting a full limit. It's a big responsibility but I do it for all of us....lol

Sent from my Pixel 2 XL using Tapatalk

haha no kidding eh, hoping I can put one in the bed of the truck in a month!

Alright well motivation has been really low but here's an update.

Had to do a bit of work to the wife's car so I rigged this up to get the truck in and out of the garage haha,

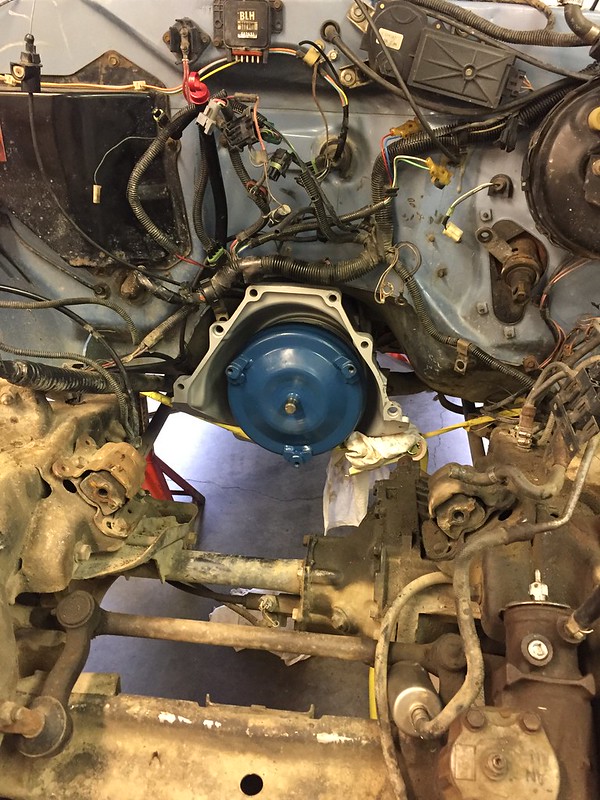

Finished pulling off the front clip and immediately realized how I should have done this in the first place when I was swapping the motor. Would have spent 2 hours pulling the front end off and probably saved 8 hours with the swap. That's the thing about hindsight I guess.

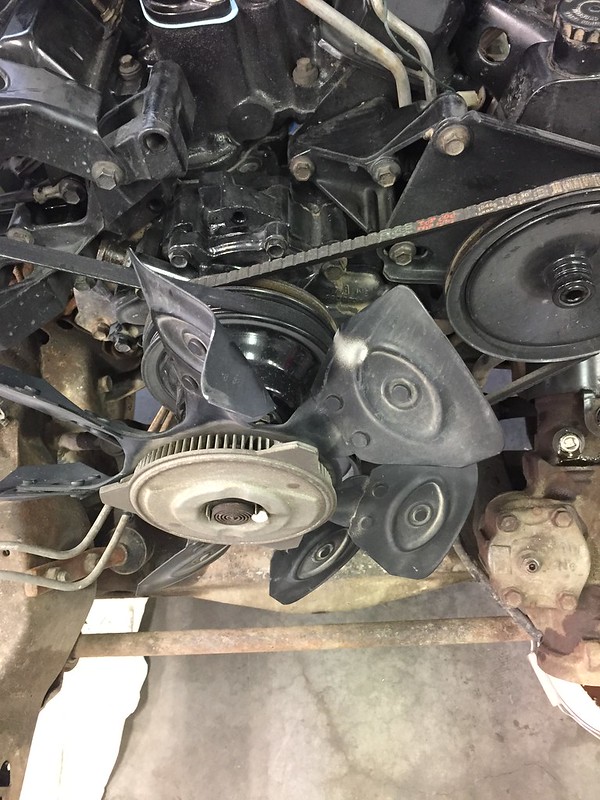

Pulled the rad off and quickly realized how lucky we were to able to drive home that night. Another km or two faster and the clutch fan would have severed these fins for sure.

One of these blades is not like the other. Can't believe it didn't puncture the rad.

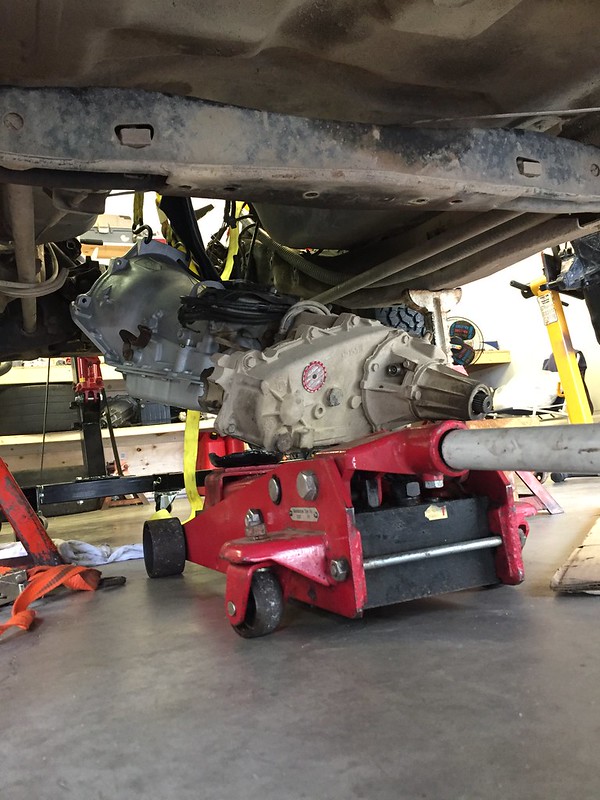

We were having a pretty noticeable rattle coming from the trans the last few trips. It would only occur when the torque converter locked out (4th gear) and under low rpm, lugging conditions. After doing some googling it seemed pretty apparent it was the torque converter starting to come apart. Since I currently had no leads on rust free body panels I decided to yank the trans and deal with it now.

A couple hours wrenching after work it was ready to come out.

Everything I had read prior to doing the swap initially suggested pulling the motor/trans/transfercase as an entire assembly and I've got to say this was way more of a pain then yanking them separately. You pretty much have to get the engine vertical to clear the front differential.

Then use a come-along or ratchet strap to get the t-case to tip up. Doing this solo was incredibly tricky haha.

Breaking it all down when it's apart was nice and easy however.

Found another rad at the local yard in brand new shape with the sticker on it,

Dropped the trans pan. The magnetic pick up looked pretty good for never being touched in 30 years.

I drained the oil from the motor to find this nightmare. Yup, that's coolant in the oil. Albeit a very small amount but still a very bad thing. I'm guessing intake gasket or maybe timing cover gasket. It can't be a head gasket as there is absolutely no oil in the cooling system. I've done 2 previous oil changes and have seen nothing but clean oil previously, so this is definitely a new issue in the last 500km's since the previous oil change. Potentially triggered by the collision?

So how it sits currently. I've been checking the yard on a biweekly basis and also the local classifieds for a passenger fender, hood and core support.

The current to do list

- confirm torque converter is failing and not the trans,

- tear apart bottom of end of motor and ensure the bearings haven't been damaged by the coolant

- secure body panels & paint them

- reassemble

Coyotesight

New member

Great thread, I had an old s15 as my first truck. Good luck, with the build, and the fishing!

Andrew_S

Observer

Thanks for the good words guys. Been waiting on parts to come in the mail and have also been super busy at work.

After doing some internet transmission diagnosing I had it stuck in my head the torque converter was on it's way out.

I spotted this 700r4 w/ t-case and torque converter for $150 in the classifieds and decided I would try and go this route and swap out my Torque converter for this one.

It seemed like a good idea at the time as a new torque converter was around $300 after tax.

I decided to tear down the trans just to see how involved a rebuild would be and establish the state of this "good" transmission as the previous owner stated.

Holy cow, there's a fair bit going on in these 700's. After the tear down I realized two things; 1 - the trans was in really bad shape, clutches were destroyed, plate was broken, on and on, 2 - there was no way I was going to learn how to rebuild this trans in a timely manner and have confidence in the final product.

I decided to play it safe and take the trans to a local rebuilder and toss the idea of just swapping out the torque converter.

I was able to make use of the rear plate that adapts the 700r4 to the np207, as I had stripped out on the bolts that mounts to the cross member.

Couldn't be happier with the shop I brought the trans to. Dropped it off and a couple hours later they had a diagnosis for me. The input sprag was starting to come apart and literally fell into pieces on the bench once removed, the cause of the rattling. 3-4 clutches were showing a bit of wear as well. After talking it over, to reseal and just do a point fix/reassemble was only going to be about $250 cheaper then a full rebuild so I opted to just get it completely done and hopefully (knocks on wood) not have to worry about it again anytime soon.

It has a new "beast" sunshell, heavy duty 3-4 clutches, rebuilt torque converter, and a complete overhaul kit.

Yesterday I got it mated back up to the TC and hopefully get it back in the truck this afternoon.

After a lot of thinking I narrowed the coolant in the oil down to the intake gasket.

So I pulled the intake and sure enough the back passenger corner had lost it's contact with the gasket.

I've learned this now but apparently an aluminium intake on cast iron heads needs to be re-torqued after it's been heat soaked a few times.

I did not do this...

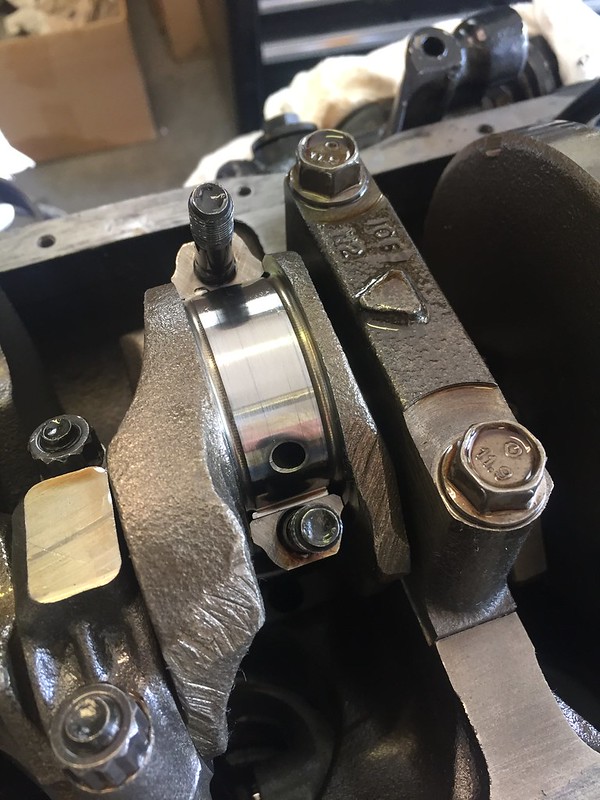

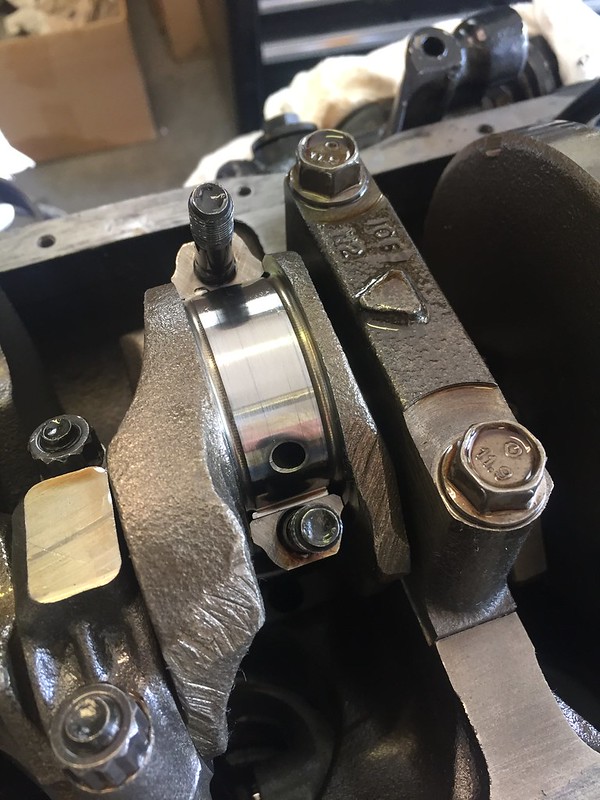

You can see in this pic great contact area on the gasket,

and on this one, not so much. The nuts on the studs on this back corner of the intake had also loosened up significantly.

A pretty good indicator I should have checked them periodically during the break in.

So hitting the doe was almost a god send because if i had kept running the engine with the contaminated oil it would have not been a good ending.

I pulled all the rod and main bearings and everything looked great.

I also gave the cam a flashlight inspection and couldn't see any glaring damage there either.

I got a little excited one afternoon when this popped up on pick n pulls inventory in Seattle. After getting some better pics, it turned out to be not worth the drive.

I've also been trying to salvage what I can from the collision, before/after

We've been improvising and getting out when we can in-spite of being truckless.

Found this guy crawling into the garage one afternoon, such a neat insect.

and how it all currently sits, '84 just got a new battery and waiting on a new intake set up for it, and the '86 is crying for some body panels and intake gaskets.

After doing some internet transmission diagnosing I had it stuck in my head the torque converter was on it's way out.

I spotted this 700r4 w/ t-case and torque converter for $150 in the classifieds and decided I would try and go this route and swap out my Torque converter for this one.

It seemed like a good idea at the time as a new torque converter was around $300 after tax.

I decided to tear down the trans just to see how involved a rebuild would be and establish the state of this "good" transmission as the previous owner stated.

Holy cow, there's a fair bit going on in these 700's. After the tear down I realized two things; 1 - the trans was in really bad shape, clutches were destroyed, plate was broken, on and on, 2 - there was no way I was going to learn how to rebuild this trans in a timely manner and have confidence in the final product.

I decided to play it safe and take the trans to a local rebuilder and toss the idea of just swapping out the torque converter.

I was able to make use of the rear plate that adapts the 700r4 to the np207, as I had stripped out on the bolts that mounts to the cross member.

Couldn't be happier with the shop I brought the trans to. Dropped it off and a couple hours later they had a diagnosis for me. The input sprag was starting to come apart and literally fell into pieces on the bench once removed, the cause of the rattling. 3-4 clutches were showing a bit of wear as well. After talking it over, to reseal and just do a point fix/reassemble was only going to be about $250 cheaper then a full rebuild so I opted to just get it completely done and hopefully (knocks on wood) not have to worry about it again anytime soon.

It has a new "beast" sunshell, heavy duty 3-4 clutches, rebuilt torque converter, and a complete overhaul kit.

Yesterday I got it mated back up to the TC and hopefully get it back in the truck this afternoon.

After a lot of thinking I narrowed the coolant in the oil down to the intake gasket.

So I pulled the intake and sure enough the back passenger corner had lost it's contact with the gasket.

I've learned this now but apparently an aluminium intake on cast iron heads needs to be re-torqued after it's been heat soaked a few times.

I did not do this...

You can see in this pic great contact area on the gasket,

and on this one, not so much. The nuts on the studs on this back corner of the intake had also loosened up significantly.

A pretty good indicator I should have checked them periodically during the break in.

So hitting the doe was almost a god send because if i had kept running the engine with the contaminated oil it would have not been a good ending.

I pulled all the rod and main bearings and everything looked great.

I also gave the cam a flashlight inspection and couldn't see any glaring damage there either.

I got a little excited one afternoon when this popped up on pick n pulls inventory in Seattle. After getting some better pics, it turned out to be not worth the drive.

I've also been trying to salvage what I can from the collision, before/after

We've been improvising and getting out when we can in-spite of being truckless.

Found this guy crawling into the garage one afternoon, such a neat insect.

and how it all currently sits, '84 just got a new battery and waiting on a new intake set up for it, and the '86 is crying for some body panels and intake gaskets.

chilliwak

Expedition Leader

Like everyone else I am sorry to see the damage to your truck Andrew. I hope you can find some parts to make her good again. I have heard about new aftermarket parts that are available for a good price. Perhaps that might be the route to take? After all it looks like you will be keeping this truck for a while. I hope all works out well. Cheers, Chilli...

Saw this on the local craigslist....

https://wichita.craigslist.org/cto/d/1985-chevy-s10/6698391872.html

https://wichita.craigslist.org/cto/d/1985-chevy-s10/6698391872.html

Andrew_S

Observer

Like everyone else I am sorry to see the damage to your truck Andrew. I hope you can find some parts to make her good again. I have heard about new aftermarket parts that are available for a good price. Perhaps that might be the route to take? After all it looks like you will be keeping this truck for a while. I hope all works out well. Cheers, Chilli...

Thanks for the suggestion Chilli, I've got a line on a few body panels at the moment.

haha I wish this was a few thousand km's closer, I would definitely be interested.Saw this on the local craigslist....

https://wichita.craigslist.org/cto/d/1985-chevy-s10/6698391872.html

My motivation to get this back together seems to come and go in waves. This weekend was like a tidal wave.

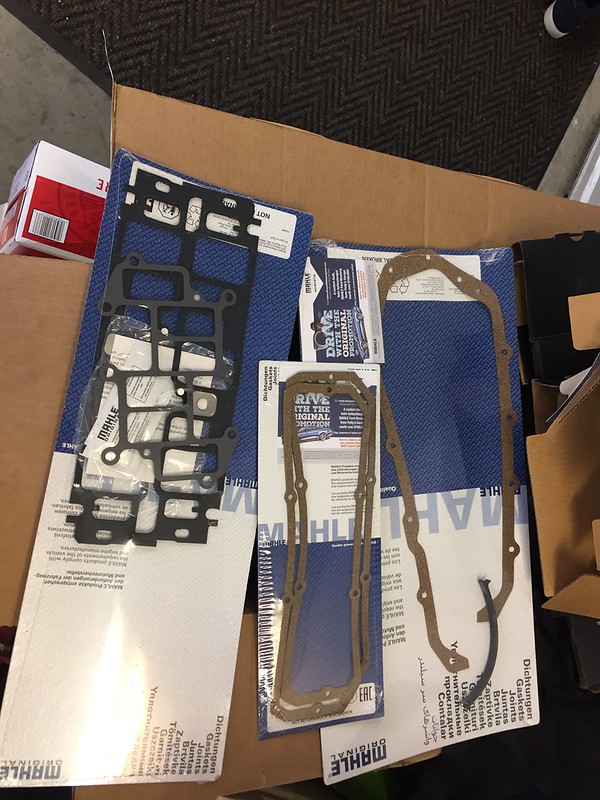

The intake and oil pan gasket set came in last week. I have to say this mahle stuff puts the previous fel-pro gaskets to shame.

Pulled the rockers and pushrods to do the intake gasket,

Setting valve lash,

All back together, hopefully for the last time in a while. (knocks on wood)

Flipped it over and did the oil pan,

I really wasn't a fan of pulling the engine/trans/t-case all together as one unit. I definitely didn't want to put them back in that way.

I used my skateboard to wheel the trans/t-case under the truck.

Then used the cherry picked to pick up the trans and jack to lift the t-case. This was another job I could have used someone else around.

After a lot of screwing around, up on the cross member with a strap supporting the front.

Dropped the 3.4 in next,

Getting pretty good at this,

I decided to flush the trans cooler lines and new rad trans cooler with some break clean and a blast of compressed air, glad I did

New muffler came in as well,

Managed to salvage the tailpipe and midpipe from the cat,

Set it all in place under the truck, tacked it and then welded it up on the bench. Prior to this the exhaust was an absolute nightmare to take apart due to the hanger configuration, it involved dropping the trans cross member, unbolting and sliding off the cat and a number of other steps. Now it takes 2 - 13mm bolts and it slides right out.

Just need to get some rod and fab up a couple more hangers,

Getting there, trans shop suggested I run dex 6, they said it's a really great fluid.

Just about ready to fire it up. A small handful of things left to finish up.

As I previously mentioned I've got a line on a fender and core support and just need to find a hood now.

Andrew_S

Observer

A side post off topic,

I went and looked at this corolla last week for the wife. It was absolutely perfect on paper, one owner with the entire service record history receipts and everything. It had 240k km's on it, not bad for an '89. It was fwd with an awd function. Small lift and new tires, interior was mint and only $2500.

Once I got there and started giving it a once over there was a quite a bit of work to be done. It needed both front CV's, rear brake cylinders, rear diff was leaking, front diff was leaking, had a bad oil leak, needed a fuel sending unit, and it had a bad head gasket. Great car, but not for $2500. Owner wouldn't even budge on their price.

A buddy from work came over last week and we did the heater core on his '79 camaro. What a ********** of a job.

He just got a new 383 built for it with some nice aluminium heads.

It was his dads car and he grew up in it, now his dad has passed it onto to him.

Getting a new intake pieced together for the '84 currently. Just need another coupler and a length of 4" aluminium pipe.

The wife did the berg lake hike this weekend which is known for being the most beautiful hike in Canada.

When she got back she sent me these photos.

Pretty jealous I didn't get to go with her.

I went and looked at this corolla last week for the wife. It was absolutely perfect on paper, one owner with the entire service record history receipts and everything. It had 240k km's on it, not bad for an '89. It was fwd with an awd function. Small lift and new tires, interior was mint and only $2500.

Once I got there and started giving it a once over there was a quite a bit of work to be done. It needed both front CV's, rear brake cylinders, rear diff was leaking, front diff was leaking, had a bad oil leak, needed a fuel sending unit, and it had a bad head gasket. Great car, but not for $2500. Owner wouldn't even budge on their price.

A buddy from work came over last week and we did the heater core on his '79 camaro. What a ********** of a job.

He just got a new 383 built for it with some nice aluminium heads.

It was his dads car and he grew up in it, now his dad has passed it onto to him.

Getting a new intake pieced together for the '84 currently. Just need another coupler and a length of 4" aluminium pipe.

The wife did the berg lake hike this weekend which is known for being the most beautiful hike in Canada.

When she got back she sent me these photos.

Pretty jealous I didn't get to go with her.

chilliwak

Expedition Leader

Beautiful pics from the hike. Also, I am glad tosee your truck coming back together Andrew. I am curious why you are running a cat and that thin pipe exhaust? Dual exhaust and even some headers would not only give you way more power but your truck would sound cool too. In the summer I am around Kelowna so if you want a hand I can send you my tlf. nummber if you need help. Who knows maybe we could go fishing. Thanks for keeping us updated with your build. Cheers, Chilli...

Similar threads

- Replies

- 2

- Views

- 261