You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1986 GMC S-15

- Thread starter Andrew_S

- Start date

Andrew_S

Observer

You're thread updates are literally the one thing I always look forward to on this forum. If I could accomplish half of what you do id be happy....and your adventures always look like you are living your best life....really makes me hate Edmonton!

Yeah Edmonton is a tough spot, bit of a drive to get anywhere. Some pretty awesome fishing not to far away though!

Some of those were truly monsters. I kept telling the wife I wouldn't want to go picking mushrooms again after being spoiled like that.If my dad (In northern Michigan) saw mushrooms that big, he'd faint. Nice haul!!!

Got a bit more done yesterday.

First thing up was wiring up a 250 volt plug in the garage. This is one of those things once you do it, you're like why did I wait so long to do this?

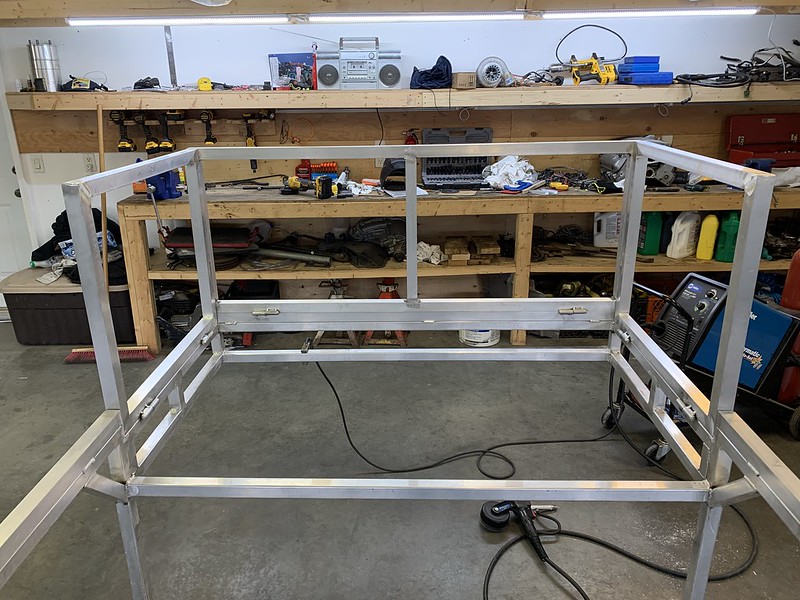

Tacked the other 2 flip up walls into place.

Folded down

Clearanced both side walls for the front hinges. This is the stuff that takes forever, cutting out and reboxing back in these two notches is an easy hour.

These took far to long to track down

2 point, locking flush mount flap handles/assemblies.

I spoke to about 6 different companies before I found one that would ship to me. Then I just about choked when they wanted $650 for two sets...

I ended up calling the manufacturer and had these drop shipped from them for $180. They showed up less then 24 hours after ordering. Unreal service. Stoked on these, quality stainless steel and skookum parts.

Inspired by the handles I got started on the 1st rear door,

A little red green inspiration for hinges.

After that I started working on the bed platform

Bed measures 6'4" and 5' wide

I'm guessing another solid 5-6 days and I can start skinning the outside walls.

Last edited:

Andrew_S

Observer

Got out yesterday and sighted in the 6.5. What a lovely gun to shoot. Got it dialed in at 200 yards and we were getting nice groupings so easily.

Pushed through a road that hadn't been driven yet this spring. Had to drag a couple of trees off the road and helped a guy get his dodge out of a deeper section of snow.

We ended up seeing 4 rabbits, a grouse, a juvenile moose, 8 white tail and a few mulies on our way through the road. Lots of fresh poop but no black bears. We also found a patch of false morels (poisionous)

Got a bit more done on the camper today. Despite the miter saw trying to take a couple of my digits. I was just being an idiot and trying to hold a short chunk of 1x1 while cutting a 45*. Sure enough the blade picked it up and it was like a gun shot going off. The piece somehow smashed my thumb and my index finger and then proceeded to do some more damage.

Super close call. I even had the forethought to use a clamp and just ignored that thought. You can see it stripped the teeth off at 1 & 6 o clock.

Damaged my buddies saw a bit too...

Started to finalized the 1st rear door,

All done and ready for a hinge. Stumbled around most of the day and didn't get to much done. Figured out today I'm 8 days into this now.

Pushed through a road that hadn't been driven yet this spring. Had to drag a couple of trees off the road and helped a guy get his dodge out of a deeper section of snow.

We ended up seeing 4 rabbits, a grouse, a juvenile moose, 8 white tail and a few mulies on our way through the road. Lots of fresh poop but no black bears. We also found a patch of false morels (poisionous)

Got a bit more done on the camper today. Despite the miter saw trying to take a couple of my digits. I was just being an idiot and trying to hold a short chunk of 1x1 while cutting a 45*. Sure enough the blade picked it up and it was like a gun shot going off. The piece somehow smashed my thumb and my index finger and then proceeded to do some more damage.

Super close call. I even had the forethought to use a clamp and just ignored that thought. You can see it stripped the teeth off at 1 & 6 o clock.

Damaged my buddies saw a bit too...

Started to finalized the 1st rear door,

All done and ready for a hinge. Stumbled around most of the day and didn't get to much done. Figured out today I'm 8 days into this now.

Andrew that looks like a real gem of a truck. I haven't seen one that nice since about 1990.

I REALLY hope that things go well with your 60-degree 2.8 V6. Back in the mid-'90s, I used to make a pretty decent living replacing those after they failed. The mechanism of failure was always the same- the coolant didn't get changed every two years, and the resulting pH shift would result in electrolysis eating away the intake manifold until the gaskets failed, dumping the coolant into the crankcase. Most engines suffered a catastrophic lower end failure right after that, as coolant is not a very good lubricant. That's probably why we don't see many 2.8-powered vehicles on the road anymore...

I REALLY hope that things go well with your 60-degree 2.8 V6. Back in the mid-'90s, I used to make a pretty decent living replacing those after they failed. The mechanism of failure was always the same- the coolant didn't get changed every two years, and the resulting pH shift would result in electrolysis eating away the intake manifold until the gaskets failed, dumping the coolant into the crankcase. Most engines suffered a catastrophic lower end failure right after that, as coolant is not a very good lubricant. That's probably why we don't see many 2.8-powered vehicles on the road anymore...

TwinDuro

Well-known member

The camper is lookin’ amazing @Andrew_S! Keep up the great work; I’m digging all the little touches in the aluminum Fab. As they say, the Devil’s in the details.

Close call on the saw!!! I’ve been there and done that (usually with hardwood) and it’s a wake up call for sure! Be safe and watch those digits!

As @MTVR said, that exact issue reared it’s ugly head on my ‘85 Celebrity. Thankfully, the intake and gaskets degraded in a way that only allowed oil into the coolant but not coolant into the oil, which I was thankful for.

Close call on the saw!!! I’ve been there and done that (usually with hardwood) and it’s a wake up call for sure! Be safe and watch those digits!

As @MTVR said, that exact issue reared it’s ugly head on my ‘85 Celebrity. Thankfully, the intake and gaskets degraded in a way that only allowed oil into the coolant but not coolant into the oil, which I was thankful for.

Andrew_S

Observer

Wait, you’re borrowing a saw to cut aluminum and you aren’t even using a non-ferrous cutting blade? Common man, you know better! I do love following along though!

I've got to be honest, I didn't know any better. Right at the beginning I did buy that dewalt 60 tooth carbide blade and honestly it worked like a hot damn. The first store I called about a new one showed me the error in my ways. Glad I didn't loose you. You'll be happy to see this.

Andrew that looks like a real gem of a truck. I haven't seen one that nice since about 1990.

I REALLY hope that things go well with your 60-degree 2.8 V6. Back in the mid-'90s, I used to make a pretty decent living replacing those after they failed. The mechanism of failure was always the same- the coolant didn't get changed every two years, and the resulting pH shift would result in electrolysis eating away the intake manifold until the gaskets failed, dumping the coolant into the crankcase. Most engines suffered a catastrophic lower end failure right after that, as coolant is not a very good lubricant. That's probably why we don't see many 2.8-powered vehicles on the road anymore...

That's interesting about the coolant. My understanding about the intake manifold gasket failures is that is was due to the iron heads/block and aluminum intake manifold. The intake would expand/contract at a different rate and over time cause the gasket to fail. Good to know.

The camper is lookin’ amazing @Andrew_S! Keep up the great work; I’m digging all the little touches in the aluminum Fab. As they say, the Devil’s in the details.

Close call on the saw!!! I’ve been there and done that (usually with hardwood) and it’s a wake up call for sure! Be safe and watch those digits!

As @MTVR said, that exact issue reared it’s ugly head on my ‘85 Celebrity. Thankfully, the intake and gaskets degraded in a way that only allowed oil into the coolant but not coolant into the oil, which I was thankful for.

Thanks!

Yeah it was an easy lesson learned. That's interesting it let oil into the coolant and not vice versa.

If you guys look back toward the beginning, you'll see that this truck is a 3.4l now.

I see the thread also just got move to Midsize... A bit of a stretch, perhaps...

When I originally rebuilt the 3.4 I didn't retorque my intake bolts after a couple of heat soaks and sure enough I started getting coolant in my oil. Fortunately I caught it immediately before I wiped out the lower end.

Yeah I requested the move. Maybe better suited for a smallsize category in the future lol.

Got a bit more done today. Nicole trying out the bed for size.

The goal today was to support the side windows properly. Found a position we could both agree on. Basically centered on the bed.

All tacked together

It's so nice to be able to flip this thing all over the place for welding

after burning through a 1lb spool, the top box is now fully welded

Nicole spent a good hour wire brushing all the welds

Now for a trial run

Fully popped up in the final position. Getting there.

In order to maximize the useable space the bed will be able to pivot up to the ceiling out of the way. Bed down.

Bed up. Tips up to almost 80* and triples the useable floor space.

I have a bad habit of starting new projects before I finish the previous ones. So keeping things on par with that. I picked this up last week.

I was walking through the junkyard with nicole looking for another canopy window and spotted this gem. '92 laredo.

I jokingly said to her that's the front axle I want to put under the truck one day and she said "well are you going to buy it?" - Did not expect that response at all. It's a high pinion dana 30 with the solid passenger side axle, no CAD.

I swapped out the knuckles for some off another WJ in the yard for the high steer. This thing will get a full overhaul, locker, regear etc.

It's going to sit for a bit but one day soon this truck is going to see a sas.

Lastly, the previous owner left a parting message on the dash of their jeep. Hit me right in the heart strings.

That's it for now. Maybe get some more stuff knocked out tomorrow.

Andrew_S

Observer

Slow day today but got a bite more done.

Added a couple cross bars in the cab over bed. Also discovered I inadvertently built the bed tray to slide forward as well.

Started on the big gate,

Checking to make sure both gates will work in unison.

Figuring this all out with gasketing, struts and locks/handles was probably one of the bigger tasks on this whole build.

Ran out of 1" tubing to finish the big door. Also had to step away and pull the trans on the '84 again.

3rd gear has been grinding since the rebuild. Taking it back to the shop tomorrow. On the brighter side check out the time stamps.

Hopefully I don't get another chance to beat that time in the near future.

Added a couple cross bars in the cab over bed. Also discovered I inadvertently built the bed tray to slide forward as well.

Started on the big gate,

Checking to make sure both gates will work in unison.

Figuring this all out with gasketing, struts and locks/handles was probably one of the bigger tasks on this whole build.

Ran out of 1" tubing to finish the big door. Also had to step away and pull the trans on the '84 again.

3rd gear has been grinding since the rebuild. Taking it back to the shop tomorrow. On the brighter side check out the time stamps.

Hopefully I don't get another chance to beat that time in the near future.

Andrew_S

Observer

Haven't got a cance to do anything yet this week besides pick up material.

A buddy of mine came over so we did test fit it on the truck again to make sure I didn't severely mess anything up or miss anything.

First good luck at how everything works.

Very cool to stand up inside of it on the truck and get a real feel for the size. Getting pretty excited to try it out for real.

A buddy of mine came over so we did test fit it on the truck again to make sure I didn't severely mess anything up or miss anything.

First good luck at how everything works.

Very cool to stand up inside of it on the truck and get a real feel for the size. Getting pretty excited to try it out for real.

BlueLantern

New member

Looking great!

Andrew_S

Observer

^Thanks guys. Twin Duro, yeah I'm not going to lie it surprised me how tall it looks on the truck popped up.

Getting down to some of the nitty gritty stuff.

Found the back window on friday. Got it and the back gate all put together yesterday.

Pulled this out of a raider canopy. The only thing better then the price ($40) is the fit. It is the absolute perfect size.

The rest of the day I spent finish welding and touching up spots.

The front of the camper is going to have a plate for the front struts and I think we may mount the lights up there as well.

After that we did a little scouting for the upcoming season.

Bumped a few nice white tails and mulies.

Then we got out for a quick paddle at a high elevation lake.

Puffballs are starting to pop up.

Puffball, onion and duck fry up.

Getting down to some of the nitty gritty stuff.

Found the back window on friday. Got it and the back gate all put together yesterday.

Pulled this out of a raider canopy. The only thing better then the price ($40) is the fit. It is the absolute perfect size.

The rest of the day I spent finish welding and touching up spots.

The front of the camper is going to have a plate for the front struts and I think we may mount the lights up there as well.

After that we did a little scouting for the upcoming season.

Bumped a few nice white tails and mulies.

Then we got out for a quick paddle at a high elevation lake.

Puffballs are starting to pop up.

Puffball, onion and duck fry up.

Last edited:

Andrew_S

Observer

Just ordered 10 sheets of aluminum!!!

We went for a little boot around on Sunday.

This is why we love having a smaller truck.

More puffballs

Then something a little out of the ordinary for mid June.

This was a day my laziness actually helped. So glad I never pulled the chains out of the truck.

It wasn't super deep snow but due to the melt/freeze/melt/freeze, it was nothing but ice underneath.

Hopefully some more camper updates here shortly.

We went for a little boot around on Sunday.

This is why we love having a smaller truck.

More puffballs

Then something a little out of the ordinary for mid June.

This was a day my laziness actually helped. So glad I never pulled the chains out of the truck.

It wasn't super deep snow but due to the melt/freeze/melt/freeze, it was nothing but ice underneath.

Hopefully some more camper updates here shortly.

Similar threads

- Replies

- 2

- Views

- 246