Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2003 Montero Limited - Lawrence of Arizona

- Thread starter SONICMASD

- Start date

SONICMASD

Adventurer

Good work, Chinese parts have their place and cheap manifolds is one for sure. Does it run better now?

I actually am not done with the repair yet, stay tuned!

SONICMASD

Adventurer

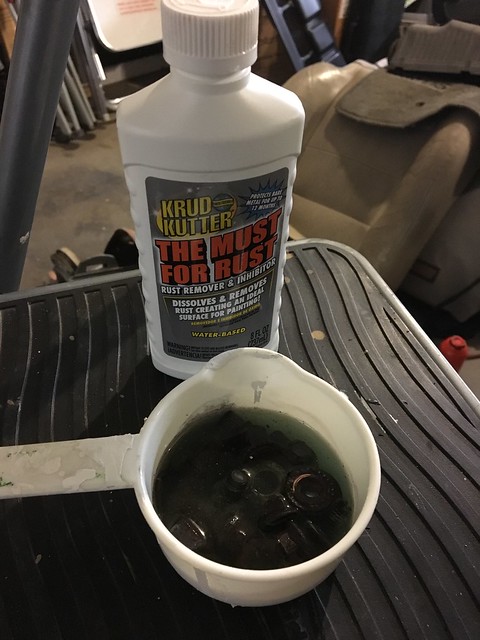

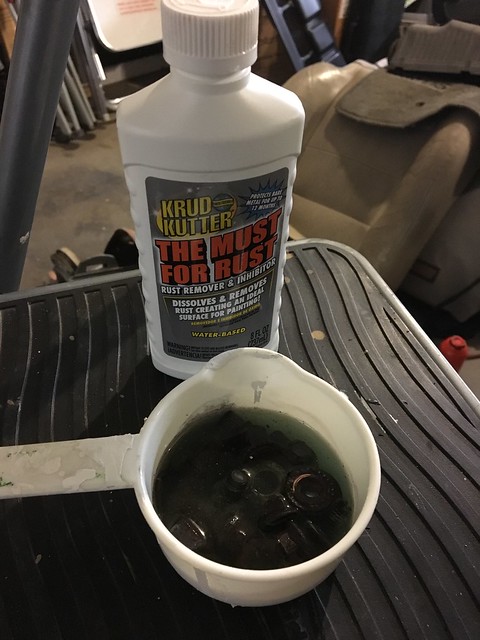

11/7/18: While waiting for the Chinese Manifolds to show up I gave the exhaust hardware a bath in Krud Kutter and wow what a difference. I bought it over a lot of other rust removing products because of a youtube video by Project Farm that compared a bunch of different brands and this one won. I was really impressed as it completely removed all rust after letting the hardware soak for about 6 hours. It did an amazing job, completley removing all rust. The red tint on some of the nuts in the final photo is actually part of the metal's color, like copper or something, and not rust.

IMG_2892

IMG_2892

IMG_2895

IMG_2895

The antenna was also in need of sprucing up so I applied several coats of Krud Kutter to it with a paint brush over the course of several hours and it made a big difference as well. Not nearly as easy or effective as soaking it, but good enough.

IMG_2902

IMG_2902

IMG_2994

IMG_2994

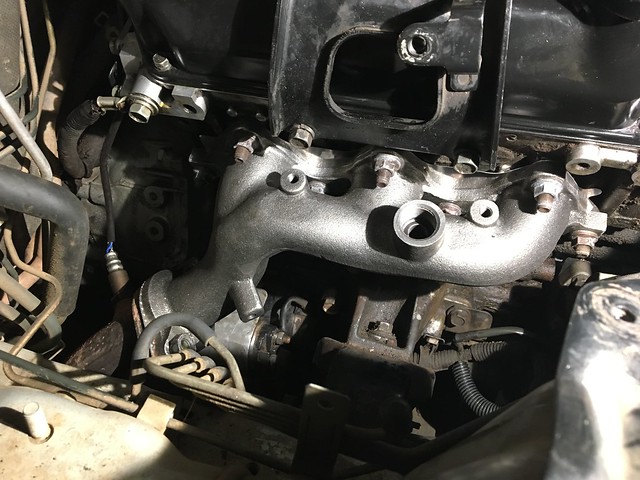

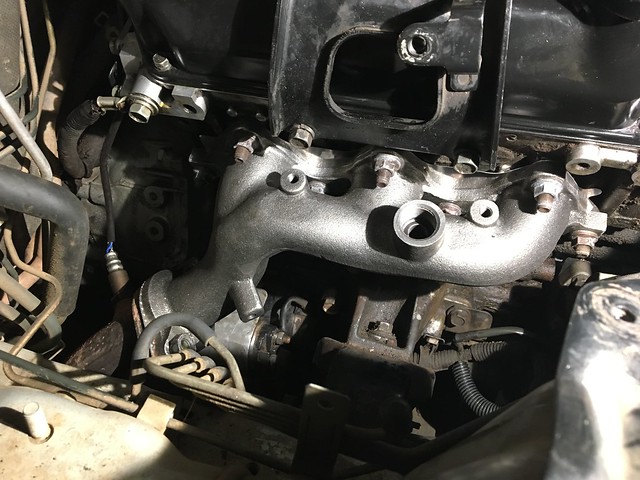

11/9/18: The manifolds arrived and they are what you would expect. Not amazing quality but they look serviceable. Some units have some casting imperfections, they have tool and grinding marks, and the holes for the heat shield are not centered on their mounts but that didn't effect the heat shield from bolting up so no harm, no foul there.

723560734791182928

723560734791182928

IMG_2912

IMG_2912

IMG_2907

IMG_2907

I got to work and set about installing the included exhaust studs on the pipe flange end of the manifold. This proved to be much more difficult than the studs that are in your cylinder head because these must go through a lot of metal. The part of the stud that has no threads must be pushed through like 1/4" of metal so that takes a lot of force.

I strapped the manifold down to my work bench (small wooden table from a fancy furniture store my parents bought like 20 years ago) using ratchet straps, no way your body weight is going to keep this thing in place when cranking on it.

IMG_2916

IMG_2916

As you can see in the above pic, you need to use 2 nuts that touch each other in opposite directions to drive the stud into place. I used a 28" breaker bar and sometimes an impact gun but found the breaker bar to be more gentle and didn't mar the nuts as bad. On the second stud, I messed up. I completely stripped its threads somehow. So I repeated the process with another stud but found that I think I also damaged the inside threads of the manifold a bit. Not a lot, but I think I removed some material there which caused the stud to go in slightly skew. I think the problem stemmed from not having the inner most nut all the way up against the shoulder of the non-threaded portion of the stud. In all the youtube videos no one does this, they just spin the 2 nuts onto the stud a bit and then crank away. But the force needed to drive these things into the manifld this deep is so much greater than when going a tiny bit into an aluminum cylinder head. So you can't have all that force just on the threads of the stud, the shoulder needs to take most of the force.

I ended up with this:

IMG_2917

IMG_2917

IMG_2918

IMG_2918

Gasket Talk

For that main manifold gasket I got the OEM one no problem from my local dealer. It is the type of gasket that is 2 really thin pieces of steel stamped together. MD303148

But for the manifold flange to exhaust pipe gasket it was a lot more work. What was in the car originally from Mitsu was a composite type gasket, you know the kind that is a lot thicker and looks kinda like a metal waffer? Well, it seems Mitsu doesn't make it that way anymore, they switched to the thin sheet metal kind I was told by my dealer. Normally that would probably be fine. But with this Chinese manifold with the one skew stud, it didn't sit as flush as the original manifold on the exhaust pipe. Not wanting to take any chances, I had to hunt down a thicker composite gasket which I figured would make up for any slight imperfections in the mating surface.

I tracked down a Mitsu dealer that had the old composite style gasket in stock and drove 60 miles from Tempe to Avondale to get it.

Ready to rock:

IMG_2952

IMG_2952

Done for the night.

IMG_2892

IMG_2892  IMG_2895

IMG_2895 The antenna was also in need of sprucing up so I applied several coats of Krud Kutter to it with a paint brush over the course of several hours and it made a big difference as well. Not nearly as easy or effective as soaking it, but good enough.

IMG_2902

IMG_2902  IMG_2994

IMG_299411/9/18: The manifolds arrived and they are what you would expect. Not amazing quality but they look serviceable. Some units have some casting imperfections, they have tool and grinding marks, and the holes for the heat shield are not centered on their mounts but that didn't effect the heat shield from bolting up so no harm, no foul there.

723560734791182928

723560734791182928 IMG_2912

IMG_2912 IMG_2907

IMG_2907 I got to work and set about installing the included exhaust studs on the pipe flange end of the manifold. This proved to be much more difficult than the studs that are in your cylinder head because these must go through a lot of metal. The part of the stud that has no threads must be pushed through like 1/4" of metal so that takes a lot of force.

I strapped the manifold down to my work bench (small wooden table from a fancy furniture store my parents bought like 20 years ago) using ratchet straps, no way your body weight is going to keep this thing in place when cranking on it.

IMG_2916

IMG_2916 As you can see in the above pic, you need to use 2 nuts that touch each other in opposite directions to drive the stud into place. I used a 28" breaker bar and sometimes an impact gun but found the breaker bar to be more gentle and didn't mar the nuts as bad. On the second stud, I messed up. I completely stripped its threads somehow. So I repeated the process with another stud but found that I think I also damaged the inside threads of the manifold a bit. Not a lot, but I think I removed some material there which caused the stud to go in slightly skew. I think the problem stemmed from not having the inner most nut all the way up against the shoulder of the non-threaded portion of the stud. In all the youtube videos no one does this, they just spin the 2 nuts onto the stud a bit and then crank away. But the force needed to drive these things into the manifld this deep is so much greater than when going a tiny bit into an aluminum cylinder head. So you can't have all that force just on the threads of the stud, the shoulder needs to take most of the force.

I ended up with this:

IMG_2917

IMG_2917 IMG_2918

IMG_2918 Gasket Talk

For that main manifold gasket I got the OEM one no problem from my local dealer. It is the type of gasket that is 2 really thin pieces of steel stamped together. MD303148

But for the manifold flange to exhaust pipe gasket it was a lot more work. What was in the car originally from Mitsu was a composite type gasket, you know the kind that is a lot thicker and looks kinda like a metal waffer? Well, it seems Mitsu doesn't make it that way anymore, they switched to the thin sheet metal kind I was told by my dealer. Normally that would probably be fine. But with this Chinese manifold with the one skew stud, it didn't sit as flush as the original manifold on the exhaust pipe. Not wanting to take any chances, I had to hunt down a thicker composite gasket which I figured would make up for any slight imperfections in the mating surface.

I tracked down a Mitsu dealer that had the old composite style gasket in stock and drove 60 miles from Tempe to Avondale to get it.

Ready to rock:

IMG_2952

IMG_2952 Done for the night.

SONICMASD

Adventurer

11/14/18: I was itching to get Lawrence back together and ready for a weekend trip to Flagstaff so I decided to go into the garage and wrench at like 10pm. I figured I could get the manifold installed and everything buttoned up in about 1-2 hours. Boy, was I wrong.

It didn't take long for things to go awry. First step: Bolt the exhaust pipe to the manifold. Problem was, when I tried to get the necessary 44 ft lbs onto the nut the skew stud would start spinning out of the manifold!

So not wanting to throw this manifold out and grab another one (I bought 10), I decided to just add a nut on the back side of the stud that I could keep a wrench on to keep it from spinning while torquing the other side. Also, just to be super safe, I added a light coat of copper gasket paste to the manifold as another precaution against leaks.

IMG_2976

IMG_2976

IMG_2977

IMG_2977

So after an hour or so of wrestling with that problem the manifold and pipe were bolted together and ready for install. Again, to be super safe and not waste my time, I decided to do a smoke test on the unit now while it was still out of the car so that I didn't go through all the trouble of installing it only to find it still leaking and have to remove everything.

I covered up all the holes in the manifold and ran the test and to my joy, it passed, no leaks.

IMG_2978

IMG_2978

Ok, so now it was about midnight and I bolted up the manifold with new gasket to the cylinder head. I torqued the nuts starting from the center outwards and took them all finger tight, then to 20 ft lbs, then to the torque spec of 33 ft lbs.

IMG_2982

IMG_2982

Then, I crawled underneath to bolt up the exhaust pipe to the y-pipe and realized my first ************** mistake. I never set the connection in place before bolting up the manifold and now it was not wanting to go into place. There was a visible gap between the pipes and I couldn't pop the pipes into place by hand.

IMG_2987

IMG_2987

So then I tried taking off a few y-pipe bolts and seeing if that would allow the two pieces to move a little and slide into place - nope. So then I tried prying on the pipe with a bar, nope. Then my most ************** idea yet - use a floor jack to try moving them into place! Luckily I stopped that stupid idea after like one pump and before putting too much pressure on this expensive 1 year old cat/y-pipe assembly. Finally I decide, just bolt it together and maybe the bolts will snug everything up into place. I do that and the connection looks ok from the outside to my naked eye but you can't really see the connection surface once it is bolted together so there is no good way to know.

I debate doing a smoke test or bolting up the manifold to the head, putting everything back together and just rolling the dice that way. I go with the later and bolt everything up, manifold, egr pipe (real PITA to get those bolts in because of lack of visibility cuz of the throttle body), heat shield, airbox, O2 sensor, connect battery, turn on car, look underneath and see a massive amount of exhaust gases coming out of the pipe connection. Back to square one.

Ugh, time to face the music. Clearly, I needed to fit the exhaust pipes together first, and then bolt the manifold to the head. So now, it's like 1am and I decide to undo everything.

I do that, fit the exhaust pipes into place but then the manifold won't fit onto the studs coming out of the head. Like the only way I can make the manifold fit is if the exhaust pipe below has the gap! So after fiddling with it some more and looking stuff up and swearing a lot it's now like 2 am. I'm thinking my options are:

1. The Chinese manifolds must be different dimensions and don't fit. I need to buy an OEM one.

2. Have a pro takeover from here which means have Ernest come over, or drive with the exhaust leak to a muffler shop and give them a crack at it.

3. Sell all my Monteros and take up a less frustrating hobby.

I have another idea - I know, the problem is that I attached the exhaust pipe to the manifold outside of the vehicle! If I attach the pipe to the y-pipe loosely it will still swivel in its mount, allowing me to then connect the manifold to the cylinder head and it. My wife wakes up as I'm having this epiphany and realizes I'm not in bed so she calls me and tells me to stop for the night and go to sleep. I tell her ok, but looking at the rig, I just can't leave it unfinished tonight for some reason.

Crack a fresh beer and take it all apart. Thank goodness I decided to only use the copper gasket paste on one side of the composite gasket or that would have added another problem to deal with.

So now we're back to where I was a week ago: The manifold is now separated from the pipe, the smoke test I did earlier worthless, the nuts on the back side of the bolts are now removed, and the last 4 and half hours a total waste. Ok, I attach the pipe to the y-pipe and low and behold, even thought it was not super easy because of the crooked exhaust stud, I got the manifold onto the head and pipe flange!

Then the hard part, getting the nuts onto the backside of the manifold, holding them in place with box wrenches while torquing the nuts on the other side of stud from below using a 12" extension. That took forever but I managed. If someone else had been with me it would have shaved 90% of the time off because I lost count of how many times I had to crawl out and then back under the truck as wrenches fell off the other side and had to be re-positioned, etc. Alright, let's button it up: heat shield, EGR pipe, airbox, O2 sensor, battery.

I fire it up, crawl underneath, and see tons of exhuast smoke coming out of the dreaded pipe to y-pipe connection and even worse from the other side of the first catalytic converter! Also, I notice that the speedo, tach, and odometer are blank - nothing on them. It's like 4am and the vehicle is way worse than when I started on this project weeks ago so I throw in the towel for the night and go to bed sore and pissed off.

It didn't take long for things to go awry. First step: Bolt the exhaust pipe to the manifold. Problem was, when I tried to get the necessary 44 ft lbs onto the nut the skew stud would start spinning out of the manifold!

So not wanting to throw this manifold out and grab another one (I bought 10), I decided to just add a nut on the back side of the stud that I could keep a wrench on to keep it from spinning while torquing the other side. Also, just to be super safe, I added a light coat of copper gasket paste to the manifold as another precaution against leaks.

IMG_2976

IMG_2976  IMG_2977

IMG_2977 So after an hour or so of wrestling with that problem the manifold and pipe were bolted together and ready for install. Again, to be super safe and not waste my time, I decided to do a smoke test on the unit now while it was still out of the car so that I didn't go through all the trouble of installing it only to find it still leaking and have to remove everything.

I covered up all the holes in the manifold and ran the test and to my joy, it passed, no leaks.

IMG_2978

IMG_2978 Ok, so now it was about midnight and I bolted up the manifold with new gasket to the cylinder head. I torqued the nuts starting from the center outwards and took them all finger tight, then to 20 ft lbs, then to the torque spec of 33 ft lbs.

IMG_2982

IMG_2982 Then, I crawled underneath to bolt up the exhaust pipe to the y-pipe and realized my first ************** mistake. I never set the connection in place before bolting up the manifold and now it was not wanting to go into place. There was a visible gap between the pipes and I couldn't pop the pipes into place by hand.

IMG_2987

IMG_2987 So then I tried taking off a few y-pipe bolts and seeing if that would allow the two pieces to move a little and slide into place - nope. So then I tried prying on the pipe with a bar, nope. Then my most ************** idea yet - use a floor jack to try moving them into place! Luckily I stopped that stupid idea after like one pump and before putting too much pressure on this expensive 1 year old cat/y-pipe assembly. Finally I decide, just bolt it together and maybe the bolts will snug everything up into place. I do that and the connection looks ok from the outside to my naked eye but you can't really see the connection surface once it is bolted together so there is no good way to know.

I debate doing a smoke test or bolting up the manifold to the head, putting everything back together and just rolling the dice that way. I go with the later and bolt everything up, manifold, egr pipe (real PITA to get those bolts in because of lack of visibility cuz of the throttle body), heat shield, airbox, O2 sensor, connect battery, turn on car, look underneath and see a massive amount of exhaust gases coming out of the pipe connection. Back to square one.

Ugh, time to face the music. Clearly, I needed to fit the exhaust pipes together first, and then bolt the manifold to the head. So now, it's like 1am and I decide to undo everything.

I do that, fit the exhaust pipes into place but then the manifold won't fit onto the studs coming out of the head. Like the only way I can make the manifold fit is if the exhaust pipe below has the gap! So after fiddling with it some more and looking stuff up and swearing a lot it's now like 2 am. I'm thinking my options are:

1. The Chinese manifolds must be different dimensions and don't fit. I need to buy an OEM one.

2. Have a pro takeover from here which means have Ernest come over, or drive with the exhaust leak to a muffler shop and give them a crack at it.

3. Sell all my Monteros and take up a less frustrating hobby.

I have another idea - I know, the problem is that I attached the exhaust pipe to the manifold outside of the vehicle! If I attach the pipe to the y-pipe loosely it will still swivel in its mount, allowing me to then connect the manifold to the cylinder head and it. My wife wakes up as I'm having this epiphany and realizes I'm not in bed so she calls me and tells me to stop for the night and go to sleep. I tell her ok, but looking at the rig, I just can't leave it unfinished tonight for some reason.

Crack a fresh beer and take it all apart. Thank goodness I decided to only use the copper gasket paste on one side of the composite gasket or that would have added another problem to deal with.

So now we're back to where I was a week ago: The manifold is now separated from the pipe, the smoke test I did earlier worthless, the nuts on the back side of the bolts are now removed, and the last 4 and half hours a total waste. Ok, I attach the pipe to the y-pipe and low and behold, even thought it was not super easy because of the crooked exhaust stud, I got the manifold onto the head and pipe flange!

Then the hard part, getting the nuts onto the backside of the manifold, holding them in place with box wrenches while torquing the nuts on the other side of stud from below using a 12" extension. That took forever but I managed. If someone else had been with me it would have shaved 90% of the time off because I lost count of how many times I had to crawl out and then back under the truck as wrenches fell off the other side and had to be re-positioned, etc. Alright, let's button it up: heat shield, EGR pipe, airbox, O2 sensor, battery.

I fire it up, crawl underneath, and see tons of exhuast smoke coming out of the dreaded pipe to y-pipe connection and even worse from the other side of the first catalytic converter! Also, I notice that the speedo, tach, and odometer are blank - nothing on them. It's like 4am and the vehicle is way worse than when I started on this project weeks ago so I throw in the towel for the night and go to bed sore and pissed off.

SONICMASD

Adventurer

11/15/18: The next day I had a similar feeling all day and as mad as I was, I couldn't repress the urge to fight again and win this battle. I don't think there is anything I can do with the exhaust leaks so I focus on the instrument cluster problem. I know about the R10 resistor solder issues on Gen3s but from what I understand that affects the fuel gauge and temp gauge mostly.

I've had issues with this cluster before in the past. Once, it displayed weird parts of the digits:

IMG_2593

IMG_2593

I had fixed that by simply undoing the negative battery cable, removing the cluster, looking the outside over and finding nothing, reinstalling it, reconnecting power and it was back to normal. I figured that it was because of the negative battery cable which was worthless. The bolt had chewed up the tightening part of the metal and no matter how tight you turned the bolt the cable could slip right off the terminal.

So today, I decided to fix that. I had a spare terminal already so I changed that out and flipped the battery box around cuz it was actually facing the wrong way and its neat little U channel for the negative cable wasn't being utilized as a result.

IMG_2992

IMG_2992

Unfortunately, it didn't fix the problem. This surprised me but I had to quit as I was out of time that day.

11/17/18: Up and at em bright and early, off to the junk yard, and I snag a cluster out of another 2003 just in case I need some parts. I posted on the facebook group and got some good info there about opening up the cluster and making some adjustments to the speedo and tach ribbons and that's what I was planning on doing but first it's good to always try the easiest thing. So I took my cluster out and laid it next to the new donor cluster and compared the ribbons and connections. Everything looked fine to me.

Donor on the left, Lawrence on the right.

IMG_3146

IMG_3146

So not seeing anything alarming on the outside ribbon I decided to try one more thing. I sprayed a bit of DeoxIt Red onto the 3 ribbons that plug the cluster into the car. I reconnected it while the DeoxIt was still wet so that it would also clean the terminals in the car. Connected the battery and turned it on and it was fixed, we're back baby! I've had numerous wins with DeoxIt, it's expensive but an amazing product that I can't recommend enough.

11/18/18: I had been replaying the 6 hour night wrenching fiasco in my head for the last 4 days and I just couldn't get my head around it. Why didn't the pipe/y-pipe connection seal properly when I set that in place first and torqued everything to spec? How did I manage to hurt the y-pipe enough to start leaking out of the other side that I didn't even touch, I didn't pry on it thaaaat hard right?

I figured I was beat but decided to figure out just how badly and pray for a miracle. Do you ever break something and then hope it fixes itself and like go out and check on it, hoping it's not actually broken and that you were just wrong? I do that sometimes.

So I hooked up the smoke machine (highly recommend, as this is now my 3rd time using it and it's already paid for itself 3x over) to the tailpipe and smoked the entire exhaust system. And to my great joy the pipes and manifold were fine! No smoke at all. Some smoke was leaking out of the muffler but I already knew that had some pin hole leaks but nothing was coming out near the passenger cat or manifold gaskets. I ran the smoke machine for way longer than normal just to be sure and stunk up the garage and neighborhood with the smell of burnt mineral oil.

How did it fix itself? It didn't. I was just too tired to think straight when I thought it was leaking. There was a lot of oil all over everything under the engine from the passenger side valve cover leak. So with the manifold off, I had been spraying degreaser all over, then gasket remover on the head/manifold area, I cleaned the grease off the starter, and off the top of the passenger side cat and all of that oil and degreaser was burning off and I mistook that for a visible exhaust leak. Now, I'm referring to the last time that I put everything back together and looked underneath at like 4am. I do think the best course of action is to not install the exhaust pipe to the manifold outside of the vehicle, but to do it first, and then the manifold. If you don't have a skew stud like I did, it shouldn't be nearly as hard to torque the 2 pipe to manifold bolts together from underneath.

And even better news, I was too overjoyed and happy to feel stupid for having overlooked this before! haha

Since then, I've put 20 miles on Lawrence with no CEL lights on and the engine sounds and runs great. I think the great exhaust manifold war of 2018 might finally be over.

Tomorrow will be the real test, My dad has gone offroading with me a few times but has never driven a 4x4, so for his birthday I gifted him the driver's seat and choice of any trail. We're gonna put at least 4-5 hours on this vehicle tomorrow so I'll be able to make a more definitive statement soon!

I've had issues with this cluster before in the past. Once, it displayed weird parts of the digits:

IMG_2593

IMG_2593I had fixed that by simply undoing the negative battery cable, removing the cluster, looking the outside over and finding nothing, reinstalling it, reconnecting power and it was back to normal. I figured that it was because of the negative battery cable which was worthless. The bolt had chewed up the tightening part of the metal and no matter how tight you turned the bolt the cable could slip right off the terminal.

So today, I decided to fix that. I had a spare terminal already so I changed that out and flipped the battery box around cuz it was actually facing the wrong way and its neat little U channel for the negative cable wasn't being utilized as a result.

IMG_2992

IMG_2992Unfortunately, it didn't fix the problem. This surprised me but I had to quit as I was out of time that day.

11/17/18: Up and at em bright and early, off to the junk yard, and I snag a cluster out of another 2003 just in case I need some parts. I posted on the facebook group and got some good info there about opening up the cluster and making some adjustments to the speedo and tach ribbons and that's what I was planning on doing but first it's good to always try the easiest thing. So I took my cluster out and laid it next to the new donor cluster and compared the ribbons and connections. Everything looked fine to me.

Donor on the left, Lawrence on the right.

IMG_3146

IMG_3146So not seeing anything alarming on the outside ribbon I decided to try one more thing. I sprayed a bit of DeoxIt Red onto the 3 ribbons that plug the cluster into the car. I reconnected it while the DeoxIt was still wet so that it would also clean the terminals in the car. Connected the battery and turned it on and it was fixed, we're back baby! I've had numerous wins with DeoxIt, it's expensive but an amazing product that I can't recommend enough.

11/18/18: I had been replaying the 6 hour night wrenching fiasco in my head for the last 4 days and I just couldn't get my head around it. Why didn't the pipe/y-pipe connection seal properly when I set that in place first and torqued everything to spec? How did I manage to hurt the y-pipe enough to start leaking out of the other side that I didn't even touch, I didn't pry on it thaaaat hard right?

I figured I was beat but decided to figure out just how badly and pray for a miracle. Do you ever break something and then hope it fixes itself and like go out and check on it, hoping it's not actually broken and that you were just wrong? I do that sometimes.

So I hooked up the smoke machine (highly recommend, as this is now my 3rd time using it and it's already paid for itself 3x over) to the tailpipe and smoked the entire exhaust system. And to my great joy the pipes and manifold were fine! No smoke at all. Some smoke was leaking out of the muffler but I already knew that had some pin hole leaks but nothing was coming out near the passenger cat or manifold gaskets. I ran the smoke machine for way longer than normal just to be sure and stunk up the garage and neighborhood with the smell of burnt mineral oil.

How did it fix itself? It didn't. I was just too tired to think straight when I thought it was leaking. There was a lot of oil all over everything under the engine from the passenger side valve cover leak. So with the manifold off, I had been spraying degreaser all over, then gasket remover on the head/manifold area, I cleaned the grease off the starter, and off the top of the passenger side cat and all of that oil and degreaser was burning off and I mistook that for a visible exhaust leak. Now, I'm referring to the last time that I put everything back together and looked underneath at like 4am. I do think the best course of action is to not install the exhaust pipe to the manifold outside of the vehicle, but to do it first, and then the manifold. If you don't have a skew stud like I did, it shouldn't be nearly as hard to torque the 2 pipe to manifold bolts together from underneath.

And even better news, I was too overjoyed and happy to feel stupid for having overlooked this before! haha

Since then, I've put 20 miles on Lawrence with no CEL lights on and the engine sounds and runs great. I think the great exhaust manifold war of 2018 might finally be over.

Tomorrow will be the real test, My dad has gone offroading with me a few times but has never driven a 4x4, so for his birthday I gifted him the driver's seat and choice of any trail. We're gonna put at least 4-5 hours on this vehicle tomorrow so I'll be able to make a more definitive statement soon!

Last edited:

SONICMASD

Adventurer

Excellent post. Thanks for the intel. I seriously hope to never (please let it be never) have to change out exhaust manifolds on my gen 3.......but just in case got me some 411.

Passenger side is actually really easy other than the Exhaust Manifold stud install. Driver side = pay a pro to do it.

SONICMASD

Adventurer

11/24/18: Test Day #4 - Gifted my dad the left seat for his bday and he looked through my AZ 4x4 Trails Book and picked the China Dam / Tule Creek Homestead trail which is rated as Moderate.

Within 5 miles of leaving my house and getting on the highway the CEL popped back on. Ugh, I guess the saga continues.

The good news is I pulled the codes and now there is only one. No more, lean condition reported. Now, only the code that says No O2 sensor activity detected so I think that pretty much means I need a new O2 sensor.

The desert is beautiful this time of year and it was great being out there. My dad drove for a bit but found it too intimidating when we would get to an obstacle because he literally has zero 4x4 experience. He was scared he was going to break my vehicle or roll it or get stuck and was too stressed out so he asked me to take over. So as I drove I explained to him what I was doing and the different strategies for tackling different obstacle types.

He enjoyed the right seat way more and was totally content with the views and navigating.

The trail to China Dam was easy, the final 100 yards had a washed out area that needed some attention but nothing a stock Gen3 couldn't do. The next portion of the trail to the homestead was harder and there was one good hill climb to best but again, a stock Gen3 could do it. And then there was one rocky outcropping/steps that needed to be climbed and I'm not so sure a stock rig could do it for clearance issues but Lawrence had zero problems.

My dad commented several times about how much smoother and more comfortable of a ride Lawrence was than Betty.

Test Findings - Reinforced the prior trials, nothing new learned today

1. Capability Offroad - Again, more than enough for 99% of what people do. This was a Moderate trail with a few obstacles but any SUV with at least 31s could probably do it. The trail was full of shiny Rubicons with 35s - total overkill and yet I never see them on the hard trails, only the ones rated Easy & Moderate.

2. Comfort (both interior, handling, and ride quality) - Gen3 > Gen2

3. Engineering Flaw - CEL knocks out your Traction Control. I had to reset my CEL codes twice on the trail to keep my traction control active - not a deal breaker but a stupid and unnecessary PITA.

4. Wheeling Style - I'm getting accustomed to Gen3 wheeling and giving obstacles more gas and letting the TC do its job. I was worried I wouldn't be able to get used to this but it's becoming second nature now.

5. Angles - I've yet to rub any part of the undercarriage on Lawrence on anything while wheeling. 33s with a 2" suspension lift are sufficient. I've rubbed my other Gen3 which is not lifted and on 31.5" tires on lots of things so it's fully ADD armored up. Also, the terrible departure angle everyone talk about has yet to be a factor. I've thought I was gonna ********** my hitch coming down off several obstacles on various trails and have yet to.

6. 3 Wheeling - I've yet to really get Lawrence to do it that much and even when it does, it's only for a brief second and only a few inches high. With as little articulation as the Gen3 has, it just goes to show how important the right line is in minimizing 3 wheeling. Next Test Day, I'm going to try finding a trail that has a lot of ruts so I can try to get it to 3-wheel a lot.

So in conclusion, nothing but good stuff from this Testing Day other than the CEL issues.

China Dam:

IMG_3225

IMG_3225

IMG_3228

IMG_3228

IMG_3229

IMG_3229

Tule Creek Homestead:

IMG_3235

IMG_3235

IMG_3232

IMG_3232

IMG_3231

IMG_3231

IMG_3234

IMG_3234

IMG_3239

IMG_3239

My favorite Sonoran Wild Edible - Pin Cushion Cactus Fruit

IMG_3241

IMG_3241

IMG_3242

IMG_3242

The rear table came in handy for lunch prep:

IMG_3240

IMG_3240

Within 5 miles of leaving my house and getting on the highway the CEL popped back on. Ugh, I guess the saga continues.

The good news is I pulled the codes and now there is only one. No more, lean condition reported. Now, only the code that says No O2 sensor activity detected so I think that pretty much means I need a new O2 sensor.

The desert is beautiful this time of year and it was great being out there. My dad drove for a bit but found it too intimidating when we would get to an obstacle because he literally has zero 4x4 experience. He was scared he was going to break my vehicle or roll it or get stuck and was too stressed out so he asked me to take over. So as I drove I explained to him what I was doing and the different strategies for tackling different obstacle types.

He enjoyed the right seat way more and was totally content with the views and navigating.

The trail to China Dam was easy, the final 100 yards had a washed out area that needed some attention but nothing a stock Gen3 couldn't do. The next portion of the trail to the homestead was harder and there was one good hill climb to best but again, a stock Gen3 could do it. And then there was one rocky outcropping/steps that needed to be climbed and I'm not so sure a stock rig could do it for clearance issues but Lawrence had zero problems.

My dad commented several times about how much smoother and more comfortable of a ride Lawrence was than Betty.

Test Findings - Reinforced the prior trials, nothing new learned today

1. Capability Offroad - Again, more than enough for 99% of what people do. This was a Moderate trail with a few obstacles but any SUV with at least 31s could probably do it. The trail was full of shiny Rubicons with 35s - total overkill and yet I never see them on the hard trails, only the ones rated Easy & Moderate.

2. Comfort (both interior, handling, and ride quality) - Gen3 > Gen2

3. Engineering Flaw - CEL knocks out your Traction Control. I had to reset my CEL codes twice on the trail to keep my traction control active - not a deal breaker but a stupid and unnecessary PITA.

4. Wheeling Style - I'm getting accustomed to Gen3 wheeling and giving obstacles more gas and letting the TC do its job. I was worried I wouldn't be able to get used to this but it's becoming second nature now.

5. Angles - I've yet to rub any part of the undercarriage on Lawrence on anything while wheeling. 33s with a 2" suspension lift are sufficient. I've rubbed my other Gen3 which is not lifted and on 31.5" tires on lots of things so it's fully ADD armored up. Also, the terrible departure angle everyone talk about has yet to be a factor. I've thought I was gonna ********** my hitch coming down off several obstacles on various trails and have yet to.

6. 3 Wheeling - I've yet to really get Lawrence to do it that much and even when it does, it's only for a brief second and only a few inches high. With as little articulation as the Gen3 has, it just goes to show how important the right line is in minimizing 3 wheeling. Next Test Day, I'm going to try finding a trail that has a lot of ruts so I can try to get it to 3-wheel a lot.

So in conclusion, nothing but good stuff from this Testing Day other than the CEL issues.

China Dam:

IMG_3225

IMG_3225 IMG_3228

IMG_3228 IMG_3229

IMG_3229Tule Creek Homestead:

IMG_3235

IMG_3235 IMG_3232

IMG_3232 IMG_3231

IMG_3231 IMG_3234

IMG_3234 IMG_3239

IMG_3239My favorite Sonoran Wild Edible - Pin Cushion Cactus Fruit

IMG_3241

IMG_3241 IMG_3242

IMG_3242The rear table came in handy for lunch prep:

IMG_3240

IMG_3240

Last edited:

SONICMASD

Adventurer

11/28/18: I got a new Denso O2 Sensor from Amazon to hopefully fix this pesky CEL. It's almost the last piece of the puzzle since I've already done everything that I know of that could cause this code other than start testing / messing with the fuel system.

I go out to the truck with a few minutes to spare in my day figuring this will take like 5 minutes - nope! It's my luck, I've removed and installed this oxygen sensor like 4 times in the last month and it's never been a problem. But it clearly sensed that it was about to go in the trash and tried to fight for its life. I have no idea what happened in the last 5 days since I installed it but it decided to like weld itself to the bung. It took a lot of effort to get it out so what was a 5 minute endeavor the last 4 times was like at least an hour this time. I got it out by cutting the wires and slipping a regular box wrench over it, then using another wrench to double the leverage and not just turn it left but then back to the right, then to the left, then to the right, little by little that would free it up.

Like this but without the heat because I don't have a torch:

To hopefully avoid this problem in the future I cleaned out the bung threads and then added a good amount of the supplied copper anti-seize that came with O2 sensor to its threads. I also added Dielectric Grease to the connector.

Old vs New:

IMG_3263

IMG_3263

It was surprising that the O2 sensor needed to be replaced because it was a Denso unit and was only like 2 years old. If O2 sensors are anything like catalytic converters, they can be damaged by mixtures that are too rich as was the case here. So that could be what ruined this O2 sensor and if this cracked exhaust manifold had been around for awhile, could have been the reason Marutuk had to get a new Y-pipe cats 2 years ago as well.

So I finish up, reconnect the battery, turn on the vehicle and notice that the instrument cluster is now back to it's game of phantom gauges - No tach, no speedo, no odo. It's like every time the battery gets disconnected this happens and I have no idea why. I tried uninstalling and reinstalling the cluster several times and it won't come back to life this time. So I'm gonna try doing the R10 solder fix to see if that fixes it. At the very least it should fix the inaccurate fuel gauge that the cluster had even when the rest of the cluster worked and that will allow me to swap the small box on the back of the cluster that contains the odometer info onto the new donor cluster I got out of the junkyard last week - but that's worst case scenario.

Anyways - after those 2 annoying set backs I'm happy to report that I have about 100 miles on Lawrence now with no CEL.

I go out to the truck with a few minutes to spare in my day figuring this will take like 5 minutes - nope! It's my luck, I've removed and installed this oxygen sensor like 4 times in the last month and it's never been a problem. But it clearly sensed that it was about to go in the trash and tried to fight for its life. I have no idea what happened in the last 5 days since I installed it but it decided to like weld itself to the bung. It took a lot of effort to get it out so what was a 5 minute endeavor the last 4 times was like at least an hour this time. I got it out by cutting the wires and slipping a regular box wrench over it, then using another wrench to double the leverage and not just turn it left but then back to the right, then to the left, then to the right, little by little that would free it up.

Like this but without the heat because I don't have a torch:

To hopefully avoid this problem in the future I cleaned out the bung threads and then added a good amount of the supplied copper anti-seize that came with O2 sensor to its threads. I also added Dielectric Grease to the connector.

Old vs New:

IMG_3263

IMG_3263 It was surprising that the O2 sensor needed to be replaced because it was a Denso unit and was only like 2 years old. If O2 sensors are anything like catalytic converters, they can be damaged by mixtures that are too rich as was the case here. So that could be what ruined this O2 sensor and if this cracked exhaust manifold had been around for awhile, could have been the reason Marutuk had to get a new Y-pipe cats 2 years ago as well.

So I finish up, reconnect the battery, turn on the vehicle and notice that the instrument cluster is now back to it's game of phantom gauges - No tach, no speedo, no odo. It's like every time the battery gets disconnected this happens and I have no idea why. I tried uninstalling and reinstalling the cluster several times and it won't come back to life this time. So I'm gonna try doing the R10 solder fix to see if that fixes it. At the very least it should fix the inaccurate fuel gauge that the cluster had even when the rest of the cluster worked and that will allow me to swap the small box on the back of the cluster that contains the odometer info onto the new donor cluster I got out of the junkyard last week - but that's worst case scenario.

Anyways - after those 2 annoying set backs I'm happy to report that I have about 100 miles on Lawrence now with no CEL.

SONICMASD

Adventurer

12/23/18: I've been working on this for awhile off and on and finished it up today.

After installing the 5th Gen 4runner wheels I kind of forgot about the center caps but after a few months, I finally got around to working on them.

As you can see, the wheel looks kind of unfinished and lets dirt get into the hub-centric ring and lugnut area easier:

IMG_2898

IMG_2898

Step 1 - remove the Toyota badges and tape over these holes on the back side.

IMG_2828

IMG_2828

Step 2 - Fill holes from the front. I used some leftover construction adhesive I had with my thinking that I wanted something waterproof. This stuff was much harder to work with and sand and in retrospect I should have just used body filler and then painted over both the front and back sides of it to seal it from moisture.

IMG_2829

IMG_2829

IMG_2830

IMG_2830

Step 3 - Sand filler smooth and paint. I used Rustoleum bedliner spray + 2 coats of Rustoleum Semi Gloss Black to match my wheels:

IMG_2901

IMG_2901

Finished product:

IMG_2899

IMG_2899

It looked better but still not right. I had thought about putting a mitsu logo in the center where the toyota one used to be but I thought it would look to blingy. Then coincidentally, someone posted on the Montero USA Facebook page about domed Mitsu decals they got on ebay for this exact purpose and looking at their pics I decided that it looked much better than my blank center caps.

So I ordered some black and silver decals on eBay from a seller in Thailand and they only took about 2 weeks to arrive. So then I sanded the center area smooth again because I didn't think they would stick very well to the bedliner texture, and re-painted again before applying the decals.

Much better:

IMG_3353

IMG_3353

IMG_3620

IMG_3620

IMG_3622

IMG_3622

After installing the 5th Gen 4runner wheels I kind of forgot about the center caps but after a few months, I finally got around to working on them.

As you can see, the wheel looks kind of unfinished and lets dirt get into the hub-centric ring and lugnut area easier:

IMG_2898

IMG_2898Step 1 - remove the Toyota badges and tape over these holes on the back side.

IMG_2828

IMG_2828Step 2 - Fill holes from the front. I used some leftover construction adhesive I had with my thinking that I wanted something waterproof. This stuff was much harder to work with and sand and in retrospect I should have just used body filler and then painted over both the front and back sides of it to seal it from moisture.

IMG_2829

IMG_2829 IMG_2830

IMG_2830Step 3 - Sand filler smooth and paint. I used Rustoleum bedliner spray + 2 coats of Rustoleum Semi Gloss Black to match my wheels:

IMG_2901

IMG_2901Finished product:

IMG_2899

IMG_2899It looked better but still not right. I had thought about putting a mitsu logo in the center where the toyota one used to be but I thought it would look to blingy. Then coincidentally, someone posted on the Montero USA Facebook page about domed Mitsu decals they got on ebay for this exact purpose and looking at their pics I decided that it looked much better than my blank center caps.

So I ordered some black and silver decals on eBay from a seller in Thailand and they only took about 2 weeks to arrive. So then I sanded the center area smooth again because I didn't think they would stick very well to the bedliner texture, and re-painted again before applying the decals.

Much better:

IMG_3353

IMG_3353 IMG_3620

IMG_3620 IMG_3622

IMG_3622

Last edited:

SONICMASD

Adventurer

12/23/18 Test Day #5: After installing my fresh new center caps it was time to break them in with some more Gen 2 vs Gen 3 testing! I had a bunch of family in town for the holidays and they wanted to go offroading so we hoped in Lawrence and headed over to Butcher Jones Cover at Saguaro Lake. I chose this spot because one of the few remaining questions I have in the Gen 2 vs 3 debate is can I get used to / handle the Gen3's even worse articulation? Ernest told me there was a lot of obstacles behind Butcher Jones that I could test this out on and boy was he right.

Shortly after you get on the trail from the start of the Butcher Jones parking lot you come up to the first big hill and there are 3 routes you can take to get over it: Easy, Medium, and Hard. I decided to go up Easy and then back down the same way via Medium to get my family and myself more broken in. Then I went up the Hard way and it was gnarly. The hill is a staircase of huge divots, probably about 4 of them, that you must traverse with speed (on account of the G3 traction control needing some wheel spin). We were looking straight up at the sky several times as the vehicle see-sawed back and forth, up and down on 3 wheels.

I don't have pictures of me going up the hill (I'm terrible about getting pics and vids when offroading, too busy having fun!) but (again coincidentally on Monteros USA Facebook) the hill at Cleghorn Trail in CA looks pretty damn similar:

48403909_10212610832938204_2472701294662385664_n

48403909_10212610832938204_2472701294662385664_n

48987533_10212615737460814_6662763133989289984_n

48987533_10212615737460814_6662763133989289984_n

Lawrence climbed his way up in one take, and when coming down from 3 wheels and onto 4, I was able to modulate my throttle and set it down pretty smoothly so as not to destroy the shocks/bump stops, etc. I went up and down dozens of other hills, ran though a tight river gully, and then headed over to Sycamore Creek and went up Widow Maker again. The Gen3 did it all, no issues.

Sitting proudly at the top of one of the many hills during this day of testing:

IMG_3624

IMG_3624

Testing Day Conclusions:

1. Again, the Gen3 is waaaay more capable than most people think and I don't think I've gotten near its limits yet.

2. Having the extra power and lower gearing is really nice. Not only for going up steep hills but also coming down them. In 4Lo, 1st gear, with 4.90s Lawrence crawls down steep hills at a perfect pace with no need to touch the brakes. In Betty, who has 4.90s as well, you do still need to use the brakes because of the higher 1st gear ratio.

3. I'm getting good at Gen3 wheeling. I was scared it would be something that I wouldn't be able to get used to because it is so different than almost any other 4x4 but it's becoming second nature. More speed, more wheels spin, don't mind lifting a wheel - just plan where it will happen and where you'll put it back down. I think it would still be terrifying to 3 wheels and tilt on a cliff edge even if you knew it was gonna happen but other than that, I don't think it's a big deal. Everyone, especially Jeep guys, are always talking about articulation and after all this wheeling I don't really get it. I guess if you're rock crawling it is way more important but that's like 1% of the people that actually wheel. My point is - yes, it's unusual at first but then I was thinking about it and the most fun I've ever had when offroading in my Gen2.5 was on big obstacles that cause me to 3 wheel. Well, now I get that fun factor more often but on a more balanced vehicle with less roll over risk.

4. As I ended with above - the Gen3 is so well balanced. The slightly wider and longer footprint is perfect and it is definitely more stable in off camber situations. I've yet to lift a rear tire in an unbalanced way, unlike with Gen2s which I have lifted a rear tire up on a few occasions when going down a hill, giving you the sensation you're about to topple head over heels.

5. Not having a locker doesn't seem to matter much. I thought this would be a much bigger con but the TC is really impressive. It has it's drawbacks as I've discussed several times before but overall it is an amazing must have. For this reason alone, 03-06 are the Gen3s of choice for me. If I decide that a Gen3 is the winner of this head to head battle then don't get me wrong, I still want a rear locker, I'm just saying it's not nearly as important as I originally thought. I think it's main benefit other than being able to take obstacles slower, would be in wet/muddy terrain where you want to 100% know you're turning your wheels evenly and not wasting any power so you get through that mud hole.

6. The smoothness on road is surprising every time. My Gen2.5 is already really nice in this department but even still, I can't help but remark every time I pull back out on tarmac after a day of offroading: "Can you believe this? We just did all that and now we're going 75mph on the highway in total comfort and smoothness in the same vehicle with nothing more than adding some air to the tires." It really does drive like a regular modern SUV on the road which blows your mind since it drives like a tank offroad.

7. The added ground clearance of the Gen3 is no joke and a really nice bonus. It is so rare that something hits the undercarriage with 13" of minimum clearance. I've gotten used to this new clearance and am just driving over the top of rocks that previously I would have had to go around or put tires on top of.

8. This was Lawrence's first trip outside of normal city driving since getting the CEL sorted out a few weeks ago. I'm happy to report that there were no CELs on this trip and all appears to be sorted out with the exhaust system.

9. Departure Angle - Continues to not be an issue. I hit my hitch today coming down a hill for the first time ever in this vehicle. For normal overlanding the slightly worse departure angle is a non-factor. More testing on steeper drop offs is needed.

So what's left to test? Not much.

1. I think need to go back to that same initial hill by Butcher Jones with Betty and see how she handles those big ruts for a direct comparison.

2. I need to do some rock wheeling. I've offroaded all over Sedona and Moab with Betty so I'm very familiar with how the Gen2 is in that terrain. Hitting Broken Arrow and Devil's Kitchen with Lawrence should answer any questions I have about how the Gen3 handles that stuff.

Stay tuned.

Shortly after you get on the trail from the start of the Butcher Jones parking lot you come up to the first big hill and there are 3 routes you can take to get over it: Easy, Medium, and Hard. I decided to go up Easy and then back down the same way via Medium to get my family and myself more broken in. Then I went up the Hard way and it was gnarly. The hill is a staircase of huge divots, probably about 4 of them, that you must traverse with speed (on account of the G3 traction control needing some wheel spin). We were looking straight up at the sky several times as the vehicle see-sawed back and forth, up and down on 3 wheels.

I don't have pictures of me going up the hill (I'm terrible about getting pics and vids when offroading, too busy having fun!) but (again coincidentally on Monteros USA Facebook) the hill at Cleghorn Trail in CA looks pretty damn similar:

48403909_10212610832938204_2472701294662385664_n

48403909_10212610832938204_2472701294662385664_n 48987533_10212615737460814_6662763133989289984_n

48987533_10212615737460814_6662763133989289984_nLawrence climbed his way up in one take, and when coming down from 3 wheels and onto 4, I was able to modulate my throttle and set it down pretty smoothly so as not to destroy the shocks/bump stops, etc. I went up and down dozens of other hills, ran though a tight river gully, and then headed over to Sycamore Creek and went up Widow Maker again. The Gen3 did it all, no issues.

Sitting proudly at the top of one of the many hills during this day of testing:

IMG_3624

IMG_3624Testing Day Conclusions:

1. Again, the Gen3 is waaaay more capable than most people think and I don't think I've gotten near its limits yet.

2. Having the extra power and lower gearing is really nice. Not only for going up steep hills but also coming down them. In 4Lo, 1st gear, with 4.90s Lawrence crawls down steep hills at a perfect pace with no need to touch the brakes. In Betty, who has 4.90s as well, you do still need to use the brakes because of the higher 1st gear ratio.

3. I'm getting good at Gen3 wheeling. I was scared it would be something that I wouldn't be able to get used to because it is so different than almost any other 4x4 but it's becoming second nature. More speed, more wheels spin, don't mind lifting a wheel - just plan where it will happen and where you'll put it back down. I think it would still be terrifying to 3 wheels and tilt on a cliff edge even if you knew it was gonna happen but other than that, I don't think it's a big deal. Everyone, especially Jeep guys, are always talking about articulation and after all this wheeling I don't really get it. I guess if you're rock crawling it is way more important but that's like 1% of the people that actually wheel. My point is - yes, it's unusual at first but then I was thinking about it and the most fun I've ever had when offroading in my Gen2.5 was on big obstacles that cause me to 3 wheel. Well, now I get that fun factor more often but on a more balanced vehicle with less roll over risk.

4. As I ended with above - the Gen3 is so well balanced. The slightly wider and longer footprint is perfect and it is definitely more stable in off camber situations. I've yet to lift a rear tire in an unbalanced way, unlike with Gen2s which I have lifted a rear tire up on a few occasions when going down a hill, giving you the sensation you're about to topple head over heels.

5. Not having a locker doesn't seem to matter much. I thought this would be a much bigger con but the TC is really impressive. It has it's drawbacks as I've discussed several times before but overall it is an amazing must have. For this reason alone, 03-06 are the Gen3s of choice for me. If I decide that a Gen3 is the winner of this head to head battle then don't get me wrong, I still want a rear locker, I'm just saying it's not nearly as important as I originally thought. I think it's main benefit other than being able to take obstacles slower, would be in wet/muddy terrain where you want to 100% know you're turning your wheels evenly and not wasting any power so you get through that mud hole.

6. The smoothness on road is surprising every time. My Gen2.5 is already really nice in this department but even still, I can't help but remark every time I pull back out on tarmac after a day of offroading: "Can you believe this? We just did all that and now we're going 75mph on the highway in total comfort and smoothness in the same vehicle with nothing more than adding some air to the tires." It really does drive like a regular modern SUV on the road which blows your mind since it drives like a tank offroad.

7. The added ground clearance of the Gen3 is no joke and a really nice bonus. It is so rare that something hits the undercarriage with 13" of minimum clearance. I've gotten used to this new clearance and am just driving over the top of rocks that previously I would have had to go around or put tires on top of.

8. This was Lawrence's first trip outside of normal city driving since getting the CEL sorted out a few weeks ago. I'm happy to report that there were no CELs on this trip and all appears to be sorted out with the exhaust system.

9. Departure Angle - Continues to not be an issue. I hit my hitch today coming down a hill for the first time ever in this vehicle. For normal overlanding the slightly worse departure angle is a non-factor. More testing on steeper drop offs is needed.

So what's left to test? Not much.

1. I think need to go back to that same initial hill by Butcher Jones with Betty and see how she handles those big ruts for a direct comparison.

2. I need to do some rock wheeling. I've offroaded all over Sedona and Moab with Betty so I'm very familiar with how the Gen2 is in that terrain. Hitting Broken Arrow and Devil's Kitchen with Lawrence should answer any questions I have about how the Gen3 handles that stuff.

Stay tuned.

offthepath

Adventurer

Great thread and a fun read, thanks.

Throw some lockers in that Gen 3 and see what you think . I'm absolutely amazed at how well my Gen 3 with arbs and 33s has been working.

. I'm absolutely amazed at how well my Gen 3 with arbs and 33s has been working.

Your right, being able to wheel all day and then drive 80 all the way home is nice.

Throw some lockers in that Gen 3 and see what you think

Your right, being able to wheel all day and then drive 80 all the way home is nice.

SONICMASD

Adventurer

I'm absolutely amazed at how well my Gen 3 with arbs and 33s has been working.

Plural? You got front and rear ARBs?! That’s a spendy mod!

I’m casualy working on the logistics of getting a factory rear locker for the Gen3. Junkyard parts would need to be imported but that’s easy. The main thing I have to confirm is exactly which parts are needed because various sources say different things. The only advantages being 1. Lower pressure, less likely to spring a leak.

But the big one being 2. Cost. I’m hoping it’ll be half the price of an ARB.

offthepath

Adventurer

Ehhh. I can be all in with lockers, winch, lifts, etc and even crawler gears for the price of a stock 100 series LC with 50k more miles.

I want a rig that works well and is capable. Its a small price to pay for performance. Also, I question what will happen to the OEM ABS pump if you over use the traction control in heavy wheeling. I've had mine shut down several times after prolonged use, generally at the crux of a climb. Now I never have to worry about that.

If you can fit an OEM locker post up the parts needed, that woukd be awesome.

BTW, harrop also makes elockers for Gen 3 monteros as another option.

I want a rig that works well and is capable. Its a small price to pay for performance. Also, I question what will happen to the OEM ABS pump if you over use the traction control in heavy wheeling. I've had mine shut down several times after prolonged use, generally at the crux of a climb. Now I never have to worry about that.

If you can fit an OEM locker post up the parts needed, that woukd be awesome.

BTW, harrop also makes elockers for Gen 3 monteros as another option.

SONICMASD

Adventurer

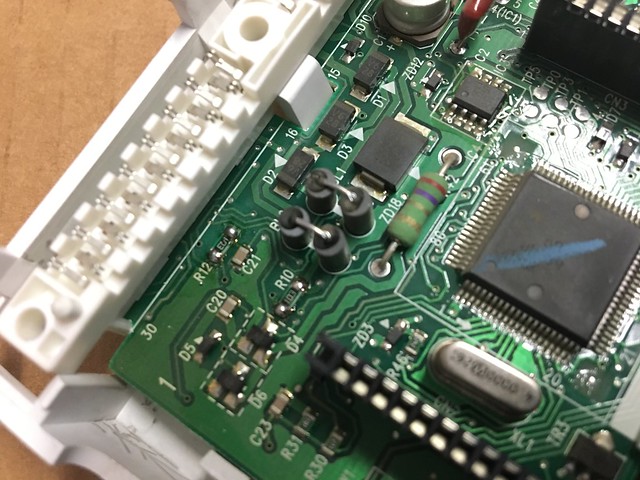

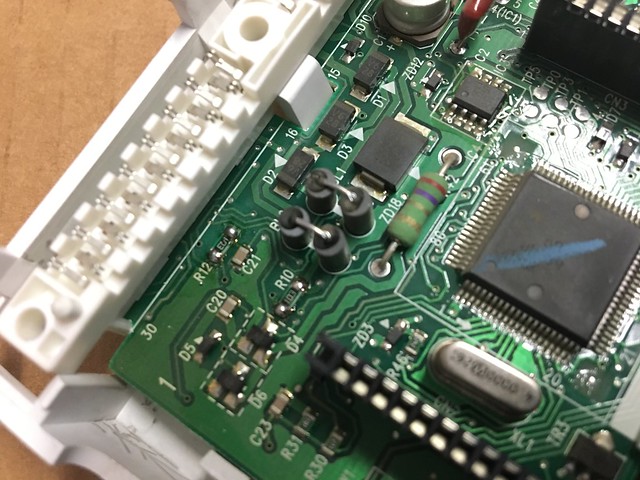

12/18/18: Instrument Cluster issues contd.

Lawrence has had a finicky fuel gauge ever since I acquired the vehicle and with the recent issue of the odo/speedo/tach not displaying I decided to try having the R10 resistor fix done to see if that solves everything. I've never soldered before so I called around and found the owner of a tv repair shop that said he'd be happy to do it and was obviously very used to soldering on tiny resistors. I had him solder up R10 as well as R12 since it looks identical and you'd think it too would suffer from the same bad soldering connection over time.

Here's the finished product:

IMG_3579

IMG_3579

So I popped this box back into the cluster, plugged it in and nope, still no tach/odo/speedo - but at least the fuel gauge came alive.

So that left me with no choice, I popped the detachable white box off again that contains the circuit board and swapped it onto the donor cluster that I got out of a 2003 Limited in the junk yard a few weeks ago. Plugged this new cluster into Lawrence and we're back!

IMG_3587

IMG_3587

This means that the original cluster must have an issue someplace else other than the main circuit board, oh well, glad I got that sorted. I can't count this as a total victory though because now the temp gauge is off. I never had a problem with the temp gauge before but now the normal operating temp is reading much lower, about 1/4 up from Cold instead of in the middle. I'm thinking either R10 needs to be resoldered or maybe it's a mechanical problem from when I was putting the cluster back together and maybe that one needle is not pressed down all the way and can't move up high enough as a result. Either way, I'll open up the cluster again one day to investigate this but for now I'm happy because I got my fuel gauge back (though it does take about 30 seconds after starting the car to come alive), odo, speedo, and tach. And also, I plan on getting a digital monitor that always displays coolant and tranny temp and has an audible alarm if things get too hot so this gauge won't really be needed anyways.

Lawrence has had a finicky fuel gauge ever since I acquired the vehicle and with the recent issue of the odo/speedo/tach not displaying I decided to try having the R10 resistor fix done to see if that solves everything. I've never soldered before so I called around and found the owner of a tv repair shop that said he'd be happy to do it and was obviously very used to soldering on tiny resistors. I had him solder up R10 as well as R12 since it looks identical and you'd think it too would suffer from the same bad soldering connection over time.

Here's the finished product:

IMG_3579

IMG_3579So I popped this box back into the cluster, plugged it in and nope, still no tach/odo/speedo - but at least the fuel gauge came alive.

So that left me with no choice, I popped the detachable white box off again that contains the circuit board and swapped it onto the donor cluster that I got out of a 2003 Limited in the junk yard a few weeks ago. Plugged this new cluster into Lawrence and we're back!

IMG_3587

IMG_3587 This means that the original cluster must have an issue someplace else other than the main circuit board, oh well, glad I got that sorted. I can't count this as a total victory though because now the temp gauge is off. I never had a problem with the temp gauge before but now the normal operating temp is reading much lower, about 1/4 up from Cold instead of in the middle. I'm thinking either R10 needs to be resoldered or maybe it's a mechanical problem from when I was putting the cluster back together and maybe that one needle is not pressed down all the way and can't move up high enough as a result. Either way, I'll open up the cluster again one day to investigate this but for now I'm happy because I got my fuel gauge back (though it does take about 30 seconds after starting the car to come alive), odo, speedo, and tach. And also, I plan on getting a digital monitor that always displays coolant and tranny temp and has an audible alarm if things get too hot so this gauge won't really be needed anyways.

Similar threads

- Replies

- 2

- Views

- 757

- Replies

- 2

- Views

- 554

- Replies

- 4

- Views

- 1K