8sixFabrication

Active member

Dec 19, 2021 at 7:32 PM

Well, there seems to be a common theme anymore with how often I can find time to work on the Tacoma. That's life I suppose. Anyhow, I managed to get some time here and there over the last week to put in some time on it.

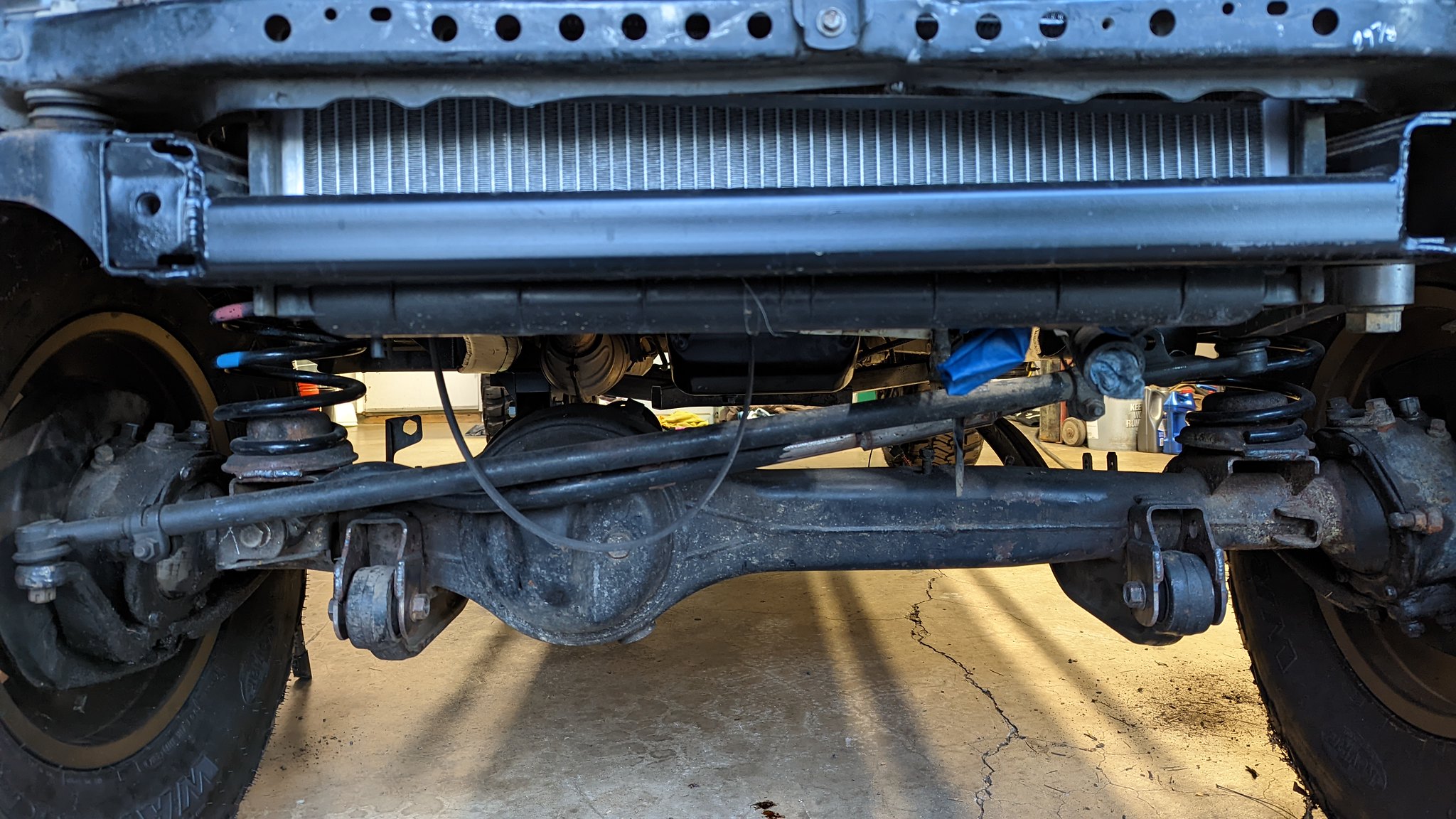

First thing I wanted to do, was make sure the wheel base was close(+/- 1/16") so I could be confident in the placement of the coil mounts both upper and lower. I made this fixture that picks up the center machine mark on the rear axle shafts, and the center machine mark on the trunion bearing cap. Somehow, out of dumb luck...... I was exactly on.

Somehow during this process, I discovered the axle was off side to side, by 3/16". I believe this mistake happened because I measured from the center holes of the lower coil mounts, and now I assume those aren't reliable.

So to confirm my findings, I took a piece of leftover delrin, and machined a little indicator that allows me to place it in the center machine marks of the trunion bearing caps and get a good side to side measurement. This confirmed my findings, and allowed me to fine tune it into within 1/32" of centered.

Luckily my lathe is in a position that helped pulling the axle over with a strap haha.

After that was done, and I re-welded the temp panhard(which I cut apart). I was worried that a bunch of other stuff was off. So I dropped the radius arms to see if they were off, and they were fine. This was good news, because I thought I might have to cut the radius arm mounts off again, and adjust them.

I verified some other measurements, and made some adjustments to the upper coil mounts.

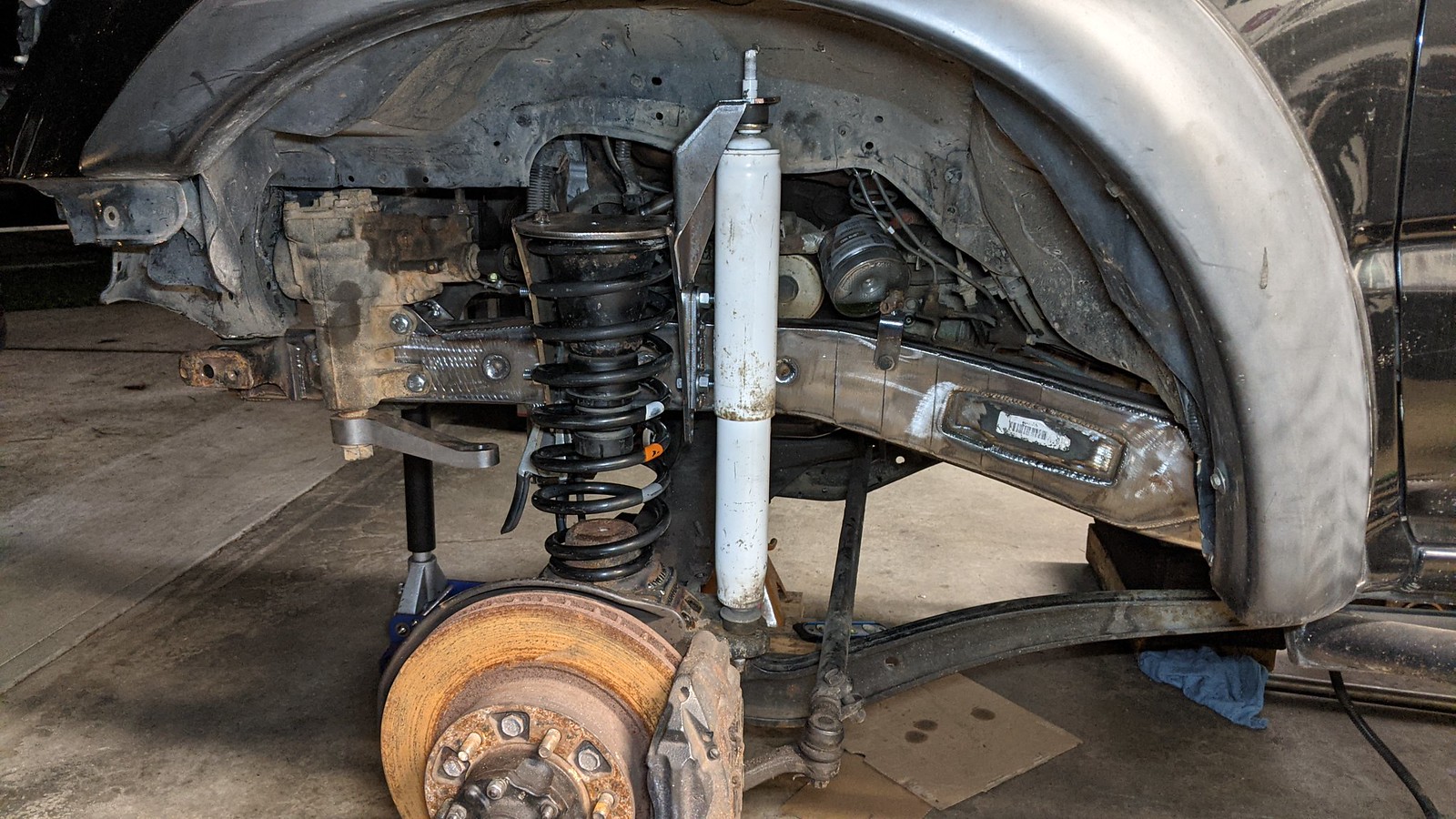

From there, I cut the tacks on the lower mounts, and dropped the upper mounts as low as they could go. This allowed me to better line up and tack in the lower mounts, so the coils now mount straight when its sitting on its own weight.

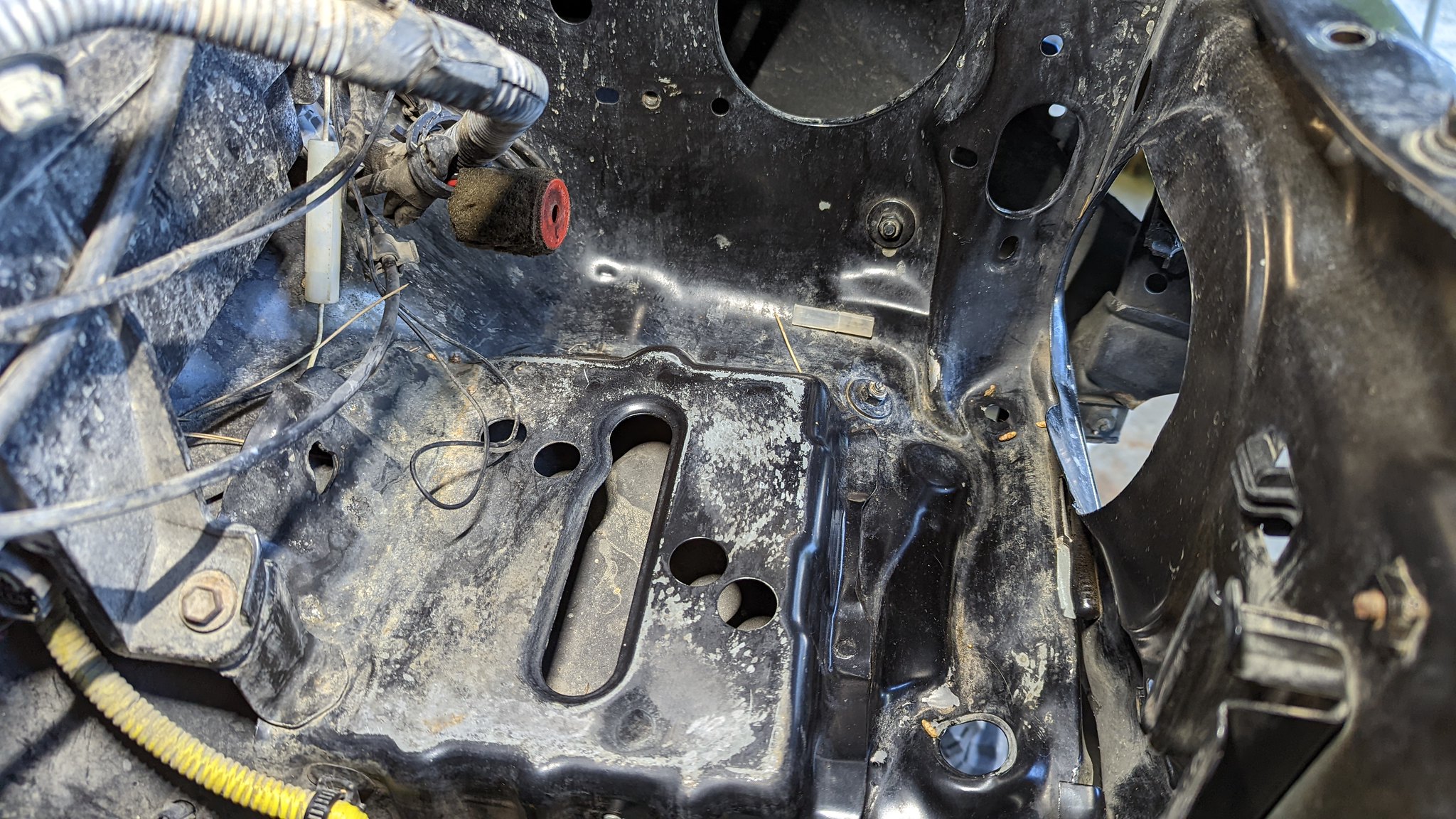

With all that taken care of, I was confident in beginning the process of welding everything up. I welded some Friday evening and a little this evening until I ran completely out of argon. I was able to get the frame plates completely welded up, and the upper coil mounts. After, I cleaned them up and wire-wheeled everything.

I'm now trying to work towards a checkpoint and have all the fab work complete on the frame and paint it all. Since its winter here in the PNW, I don't want to put it outside and have the frame rust. However, I want to have the ability to put it outside so I can bop around onto other projects like our Land Cruiser or my 85. So this is the little fire under my butt that I need to keep working on it.

This week I will get another bottle of argon so I can keep welding. From there, I will need to make mounts for the sway bar, upper shock mounts, and some other small detail work before I can begin prepping and painting the frame. More to come(hopefully)

Well, there seems to be a common theme anymore with how often I can find time to work on the Tacoma. That's life I suppose. Anyhow, I managed to get some time here and there over the last week to put in some time on it.

First thing I wanted to do, was make sure the wheel base was close(+/- 1/16") so I could be confident in the placement of the coil mounts both upper and lower. I made this fixture that picks up the center machine mark on the rear axle shafts, and the center machine mark on the trunion bearing cap. Somehow, out of dumb luck...... I was exactly on.

Somehow during this process, I discovered the axle was off side to side, by 3/16". I believe this mistake happened because I measured from the center holes of the lower coil mounts, and now I assume those aren't reliable.

So to confirm my findings, I took a piece of leftover delrin, and machined a little indicator that allows me to place it in the center machine marks of the trunion bearing caps and get a good side to side measurement. This confirmed my findings, and allowed me to fine tune it into within 1/32" of centered.

Luckily my lathe is in a position that helped pulling the axle over with a strap haha.

After that was done, and I re-welded the temp panhard(which I cut apart). I was worried that a bunch of other stuff was off. So I dropped the radius arms to see if they were off, and they were fine. This was good news, because I thought I might have to cut the radius arm mounts off again, and adjust them.

I verified some other measurements, and made some adjustments to the upper coil mounts.

From there, I cut the tacks on the lower mounts, and dropped the upper mounts as low as they could go. This allowed me to better line up and tack in the lower mounts, so the coils now mount straight when its sitting on its own weight.

With all that taken care of, I was confident in beginning the process of welding everything up. I welded some Friday evening and a little this evening until I ran completely out of argon. I was able to get the frame plates completely welded up, and the upper coil mounts. After, I cleaned them up and wire-wheeled everything.

I'm now trying to work towards a checkpoint and have all the fab work complete on the frame and paint it all. Since its winter here in the PNW, I don't want to put it outside and have the frame rust. However, I want to have the ability to put it outside so I can bop around onto other projects like our Land Cruiser or my 85. So this is the little fire under my butt that I need to keep working on it.

This week I will get another bottle of argon so I can keep welding. From there, I will need to make mounts for the sway bar, upper shock mounts, and some other small detail work before I can begin prepping and painting the frame. More to come(hopefully)