You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2005 Chevy Colorado Build Up

- Thread starter Northern Explorer

- Start date

Northern Explorer

Explorer

More Pictures

Bed pulled out in sleeping position

I'm not one to leave well enough alone. There are a few small things that I will be tweeking on the camper. I'll save that for another post in the camper section. Overall I am very pleased with the quality of the camper and I can't wait to spend my first night in it. One thing that I need to do tomorrow is put more air in my back tires. I will start out with 10 extra psi and see how that looks. I will also be putting my sway bar back on. It was great not having it without the camper but with the camper there is just too much lean around the corners. I wish I could have an electronic swaybar disconnect like the Earthroamer Jeep.

Bed pulled out in sleeping position

I'm not one to leave well enough alone. There are a few small things that I will be tweeking on the camper. I'll save that for another post in the camper section. Overall I am very pleased with the quality of the camper and I can't wait to spend my first night in it. One thing that I need to do tomorrow is put more air in my back tires. I will start out with 10 extra psi and see how that looks. I will also be putting my sway bar back on. It was great not having it without the camper but with the camper there is just too much lean around the corners. I wish I could have an electronic swaybar disconnect like the Earthroamer Jeep.

Last edited:

Northern Explorer

Explorer

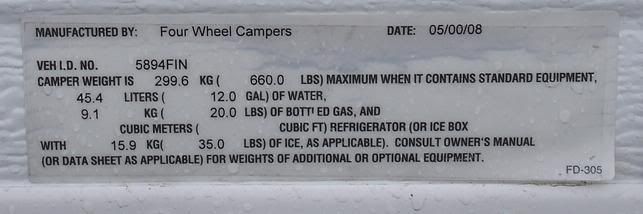

BCJC said:very nice! what comfort. any specs on the weight of the camper?

opie said:NE..that looks nice! Do you know what it weighs?

I think the 660 pounds is dry weight. The 75 amp hour AGM battery, 12 gallons of water, 20 pounds of propane, and 35 pounds of ice are all extra.

At this time I am looking into getting some air bags. The add a leafs helped but the weight of the camper (dry) sunk the back end down about two inches. I'm still glad that I put the add a leafs on because even without the camper my truck is several hundred pounds heavier then stock (rock sliders 80#, 3 skid plates ??#, truck topper ??#).

Last edited:

TheRoadie

Explorer

You made me look into this a bit. The unit is an AAM Smartbar, an option on the JK Rubicon and the Dodge Power Wagon. Big bucks option.Northern Explorer said:...I wish I could have an electronic swaybar disconnect like the Earthroamer Jeep.

But there's one for sale looks like cheap for the Jeep on Ebay: http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&item=110260708148

Didn't sell for %500 minimum bid or $550 Buyitnow, so he relisted it at $350 minimum. The bar might not fit, but somebody should buy this got the gadget value, and make it work for them.

Northern Explorer

Explorer

TheRoadie said:You made me look into this a bit. The unit is an AAM Smartbar, an option on the JK Rubicon and the Dodge Power Wagon. Big bucks option.

But there's one for sale looks like cheap for the Jeep on Ebay: http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&item=110260708148

Didn't sell for %500 minimum bid or $550 Buyitnow, so he relisted it at $350 minimum. The bar might not fit, but somebody should buy this got the gadget value, and make it work for them.

So that's how it works. Looks like it would only fit a rig with a solid front axle. At very least my skid plate would get in the way.

View attachment 19735

I'm guessing someone likes budweiser.

Northern Explorer

Explorer

On the to do list

Firestone Ride-Rite air bags

Along with the Lock-N-Lift 2 inch universal spacer kit made by Air Lift

It looks like it will be fairly easy to install.:Mechanic:

Firestone Ride-Rite air bags

Along with the Lock-N-Lift 2 inch universal spacer kit made by Air Lift

It looks like it will be fairly easy to install.:Mechanic:

Northern Explorer

Explorer

opie said:Are you skipping the AAL or adding this to it?

The add-a-leaf will stay on. It just wasn't enough for the weight of the camper The center of gravity sits about a foot behind the rear axle. But it was great with the extra weight of my topper, rock sliders, skid plates and other cargo that I had when the camper was off. This way I can just pump up the air bags (psi yet to be determined) when the camper is on and then deflate them (minimum recommended psi is 5) when I pull the camper off. Some of the people you see on here have upgraded to super heavy-duty spring in order to support the load that they carry. That's probably the way to go if you are going to have your truck loaded all the time. My camper will be off my truck 8 months of the year. A selectable suspension setup fit the bill for me.

I think the air bags will also increase stability enough that I will be able to leave my anti sway bar off. And that's a good thing.

Last edited:

Northern Explorer said:The add-a-leaf will stay on. It just wasn't enough for the weight of the camper The center of gravity sits about a foot behind the rear axle. But it was great with the extra weight of my topper, rock sliders, skid plates and other cargo that I had when the camper was off. This way I can just pump up the air bags (psi yet to be determined) when the camper is on and then deflate them (minimum recommended psi is 5) when I pull the camper off. Some of the people you see on here have upgraded to super heavy-duty spring in order to support the load that they carry. That's probably the way to go if you are going to have your truck loaded all the time. My camper will be off my truck 8 months of the year. A selectable suspension setup fit the bill for me.

I think the air bags will also increase stability enough that I will be able to leave my anti sway bar off. And that's a good thing.

I forget youve got the crew cab and most of the bed sits behind the rear axle!

Be interesting so see what your truck weighs with all your additions.

kcowyo

ExPo Original

Northern Explorer said:A selectable suspension setup fit the bill for me.

My feelings exactly. I think you'll be happy with riding on air.

FWIW, with the Airlift airbags, I run with @ 50PSI on the pavement, and up to 85PSI on the trail. When I take the camper off, I still run about 20PSI in the bags. They help keep my empty bed from bouncing around too much.

The camper looks great. I love the new interior colors over the old blues. Congrats on getting one step closer to where you're going, wherever that may be.

:beer:

Northern Explorer

Explorer

Air bags are in

I decided on the Firestone air bags over the Airlift air bags because I like how the firestone air bags sit centered on the leaf pack (and centered on the axle). The Airlift brand places the airbags a couple of inches behind the center of the leaf pack. My one concern with the Firestone airbag placement is that the jounce stops are completely removed. Hopefully they are tough enough in the event that bottoming out occurs. I’m sure that there are thousands of both style of airbags on the market and my concerns are unwarranted.

Took 5 hours. Yes, I’m the slowest mechanic on earth.

The first thing that needed to be done was to remove the “locating tabs” on the flat side of the Lock-N-Lift spacers. One set (one set = two spacers) of Lock-N-Lift spacers adds 2 inches to the length of the air bag system for vehicles with 2 inches of lift over stock. The tabs that need to be removed are only used if 2 or 3 kits are put together for vehicles with 4 or 6 inches of lift. The instructions say to use a hammer to knock off the tabs but I felt that a small saw would give me a smother finish.

with tabs

tabs removed

Showing the inside surface that gets locked to the inside surface of a second spacer.

I did need to make one run to the hardware store. A new longer bolt was required to attach the air bag to the lower bracket. The bolt that came with the air bag kit wasn’t long enough to fit through the thickness of the Lock-N-Lift spacer and the bolt that came with the Lock-N-Lift spacer didn’t have the right shaped head to be used with the lower bracket of the air bag kit. The closest thing I could find to what I needed is called a plow bolt. 3/8 inch x 1 ¼ inch did the trick.

Left: Bolt that came with air bag kit

Middle: Bolt that came with spacer kit

Right: Plow bolt

Showing how new bolt sits in bottom bracket

Showing how it looked stock. The jounce bumper needs to be removed.

Assembly completed

Now all I needed to do was run the air lines. I positioned the Schrader valves in the location of the license plate bolt holes.

30 psi raised the back end up 1 ½ inches to get it back to the height is was at before the camper was put on. I used my mountain bike shock pump to fill up the air bags. 350 pumps each to get to 30 psi. I will probably use my compressor next time.

The stability has improved significantly. Enough so that I will be able to leave the anti sway bar off.

Thanks to kcowyo for his insight on this project.

I decided on the Firestone air bags over the Airlift air bags because I like how the firestone air bags sit centered on the leaf pack (and centered on the axle). The Airlift brand places the airbags a couple of inches behind the center of the leaf pack. My one concern with the Firestone airbag placement is that the jounce stops are completely removed. Hopefully they are tough enough in the event that bottoming out occurs. I’m sure that there are thousands of both style of airbags on the market and my concerns are unwarranted.

Took 5 hours. Yes, I’m the slowest mechanic on earth.

The first thing that needed to be done was to remove the “locating tabs” on the flat side of the Lock-N-Lift spacers. One set (one set = two spacers) of Lock-N-Lift spacers adds 2 inches to the length of the air bag system for vehicles with 2 inches of lift over stock. The tabs that need to be removed are only used if 2 or 3 kits are put together for vehicles with 4 or 6 inches of lift. The instructions say to use a hammer to knock off the tabs but I felt that a small saw would give me a smother finish.

with tabs

tabs removed

Showing the inside surface that gets locked to the inside surface of a second spacer.

I did need to make one run to the hardware store. A new longer bolt was required to attach the air bag to the lower bracket. The bolt that came with the air bag kit wasn’t long enough to fit through the thickness of the Lock-N-Lift spacer and the bolt that came with the Lock-N-Lift spacer didn’t have the right shaped head to be used with the lower bracket of the air bag kit. The closest thing I could find to what I needed is called a plow bolt. 3/8 inch x 1 ¼ inch did the trick.

Left: Bolt that came with air bag kit

Middle: Bolt that came with spacer kit

Right: Plow bolt

Showing how new bolt sits in bottom bracket

Showing how it looked stock. The jounce bumper needs to be removed.

Assembly completed

Now all I needed to do was run the air lines. I positioned the Schrader valves in the location of the license plate bolt holes.

30 psi raised the back end up 1 ½ inches to get it back to the height is was at before the camper was put on. I used my mountain bike shock pump to fill up the air bags. 350 pumps each to get to 30 psi. I will probably use my compressor next time.

The stability has improved significantly. Enough so that I will be able to leave the anti sway bar off.

Thanks to kcowyo for his insight on this project.

Last edited:

kcowyo

ExPo Original

Northern Explorer said:I used my mountain bike shock pump to fill up the air bags. 350 pumps each to get to 30 psi. I will probably use my compressor next time.

Wow, what a masochist. I'd have given up at 300 pumps.

Nicely detailed install. Enjoy the ride -

:campfire:

Similar threads

- Replies

- 19

- Views

- 4K

- Replies

- 0

- Views

- 322