wrenchMonkey_

Adventurer

Started mounting the bar today after work.

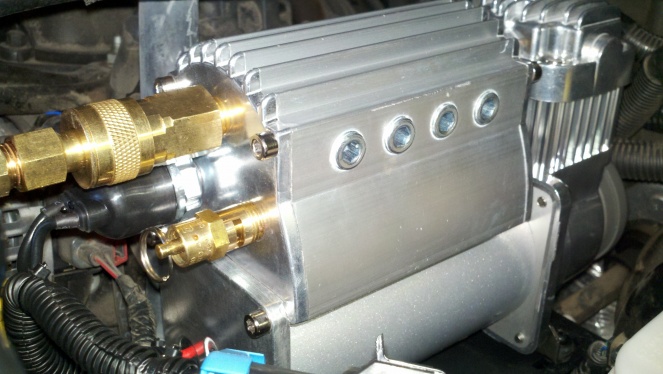

With the bumper off, first thing I noticed was that the power steering "cooler" (I use that term loosely, as its really just a loop of metal) was sitting too close and would not provide me the depth needed.

Made some brackets to relocate it about 2 inches further back. Fixed that easily enough.

Drilled and tapped the front end frame. Steel was thick enough that with a M10x1.50 bolt I was able to get 3 threads. That with some blue locktite and not overtorquing it has me with few worries. Good enough for govt work as they say. If I was doing Baha, I'd get out the MIG and weld her on.

Don't ask me why I used M10 10.9 Grade bolts, the only force this thing will have to resist is the wind at 120KMPH

After getting to this point, I stopped working on re-fitting the bumper and finished wiring up the light. The reason for this is if you notice in the above picture, and as noted before, I am putting nearly a 2 inch bar in a 1.5 inch wide space. As seen in the above picture, the top of the opening is sitting over the top of the bar and coving up a bit of the light. There is plenty of room for play on the bumper, top mounts all in OEM spots, I can rotate the bottom out about a inch out and that opens up the top of the light to be shown and covers up the bottom. Aesthetically to the eye, this looks better to me from a ground level head on view, but tonight I wanna take it out and see what throws more light. Not much data online about this brand LED ( such as a Rigid, with beam patterns and LUX readings and such) so I am not to sure I'll have to see what actually throws the most light.

While I was working on drilling and tapping all the brackets and the wiring I had the bar hooked up to a spare battery, sitting on my work bench, 1 inch away from a plastic bin. 20 minutes later, not even that hot to the touch. I am not worried about melting plastic with such low wattage/amperage on a LED compared to a Halogen/HID. Also, I'll probably be moving while using this unless setting up camp in the dark, so I account for some wind to help cool it down.

When I sort that out, I'll adjust the bottom bumper mounts ( or not ) and finish it all up.

Still have not ordered my switch, but with the exchange rate, at $40 CAD to my door for a switch.... I just cant justify that. I've got plenty of good switches around, they just don't light up and say LED LIGHT BAR on em.

With the bumper off, first thing I noticed was that the power steering "cooler" (I use that term loosely, as its really just a loop of metal) was sitting too close and would not provide me the depth needed.

Made some brackets to relocate it about 2 inches further back. Fixed that easily enough.

Drilled and tapped the front end frame. Steel was thick enough that with a M10x1.50 bolt I was able to get 3 threads. That with some blue locktite and not overtorquing it has me with few worries. Good enough for govt work as they say. If I was doing Baha, I'd get out the MIG and weld her on.

Don't ask me why I used M10 10.9 Grade bolts, the only force this thing will have to resist is the wind at 120KMPH

After getting to this point, I stopped working on re-fitting the bumper and finished wiring up the light. The reason for this is if you notice in the above picture, and as noted before, I am putting nearly a 2 inch bar in a 1.5 inch wide space. As seen in the above picture, the top of the opening is sitting over the top of the bar and coving up a bit of the light. There is plenty of room for play on the bumper, top mounts all in OEM spots, I can rotate the bottom out about a inch out and that opens up the top of the light to be shown and covers up the bottom. Aesthetically to the eye, this looks better to me from a ground level head on view, but tonight I wanna take it out and see what throws more light. Not much data online about this brand LED ( such as a Rigid, with beam patterns and LUX readings and such) so I am not to sure I'll have to see what actually throws the most light.

While I was working on drilling and tapping all the brackets and the wiring I had the bar hooked up to a spare battery, sitting on my work bench, 1 inch away from a plastic bin. 20 minutes later, not even that hot to the touch. I am not worried about melting plastic with such low wattage/amperage on a LED compared to a Halogen/HID. Also, I'll probably be moving while using this unless setting up camp in the dark, so I account for some wind to help cool it down.

When I sort that out, I'll adjust the bottom bumper mounts ( or not ) and finish it all up.

Still have not ordered my switch, but with the exchange rate, at $40 CAD to my door for a switch.... I just cant justify that. I've got plenty of good switches around, they just don't light up and say LED LIGHT BAR on em.

Last edited: