Brewdiak

kodiak conversionator

Hello all, I've been working on this truck since I bought it several years ago. At the time I had started a build thread but later deleted it however I'm going to try and put one together now in case it helps anyone and (spoiler) I'll be putting it up for sale now that it's 'done' (okay, so these DIY are never really done there's always something else that can be done - solar for one  ). A classified listing will be separate with price and more details once I get that together.

). A classified listing will be separate with price and more details once I get that together.

I started with a < 20k mile truck, it's a Wheeled Coach built for a GSA customer, and based on the clean carfax it spent the working years in the northern part of Virginia. I just ran the carfax and discovered it was in and around Alexandria, VA the same time I lived there (2009-2012) which was interesting. I don't think I ever saw it, because I have always loved the Kodiak/Top Kick trucks ever since my early years in Fire/Rescue when the large city nearby bought two matching kodiaks for rescue trucks. On that note, when I got this idea in late 2017 I was on a road trip tent camping, and got to wondering if I could turn a fire truck into a camper - I bought it from a dealer without doing any real research and just jumped in with both feet and a rental garage. For anyone still thinking about doing this, make sure to do one thing first - VALUE YOUR TIME. My biggest regret looking back is that all the time I spent building this truck would have been better spent camping and exploring with my dog, neither of us is young or healthy as we were.

So here's the way the truck was when I got it

and the way it is now

it has just under 28k miles on it.

cab as purchased

and now

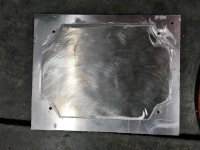

box then and now (roughly same angles)

I started with a < 20k mile truck, it's a Wheeled Coach built for a GSA customer, and based on the clean carfax it spent the working years in the northern part of Virginia. I just ran the carfax and discovered it was in and around Alexandria, VA the same time I lived there (2009-2012) which was interesting. I don't think I ever saw it, because I have always loved the Kodiak/Top Kick trucks ever since my early years in Fire/Rescue when the large city nearby bought two matching kodiaks for rescue trucks. On that note, when I got this idea in late 2017 I was on a road trip tent camping, and got to wondering if I could turn a fire truck into a camper - I bought it from a dealer without doing any real research and just jumped in with both feet and a rental garage. For anyone still thinking about doing this, make sure to do one thing first - VALUE YOUR TIME. My biggest regret looking back is that all the time I spent building this truck would have been better spent camping and exploring with my dog, neither of us is young or healthy as we were.

So here's the way the truck was when I got it

and the way it is now

it has just under 28k miles on it.

cab as purchased

and now

box then and now (roughly same angles)

Last edited: