Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2022 Ford F550 - DIY - Adventure Expedition Vehicle Build Thread

- Thread starter Vance Vanz

- Start date

Vance Vanz

Well-known member

Vance Vanz

Well-known member

Tail Light Cages - For Bumper & Camper

I'm sure Erin and I will back into something at some point (hopefully not ). If so, a little protection around the tail lights will be nice.

). If so, a little protection around the tail lights will be nice.

The lower cage in the picture (x 4) is for the bumper and the upper cage (x 2) is for the camper. I will have a set of stop/turn/tail lights up high on the camper as well, to increase visibility on the highway/open road.

Bumper Cages

Camper Cages

The nice thing about these tail lights is the color of them (when they are on) match all of the other red marker lights on the back of the camper. All of my interior and exterior lighting on the camper match/are the same shade of color. I can't stand it when the stop/turn lights don't match the marker lights on the back of a rig. Shmearth Shmoamer has this issue.

I'm sure Erin and I will back into something at some point (hopefully not

The lower cage in the picture (x 4) is for the bumper and the upper cage (x 2) is for the camper. I will have a set of stop/turn/tail lights up high on the camper as well, to increase visibility on the highway/open road.

Bumper Cages

Camper Cages

The nice thing about these tail lights is the color of them (when they are on) match all of the other red marker lights on the back of the camper. All of my interior and exterior lighting on the camper match/are the same shade of color. I can't stand it when the stop/turn lights don't match the marker lights on the back of a rig. Shmearth Shmoamer has this issue.

Vance Vanz

Well-known member

ITTOG

Well-known member

The inside, just as much work as the outside but many more systems. I plan to do the inside of my home build this summer. But it is more of a functional don't care if I damage it build.Lighting (Interior & Exterior) & Misc. Items

Testing out lights and dimmers for the build. The interior will have recessed track lighting.

View attachment 907963

View attachment 907962

The exterior will have combo white and amber lights on a dimmer.

View attachment 907965View attachment 907964

Along with all of the interior/exterior lighting, all of the 120V AC/12V DC push button (on/off/open/close) switches were purchased, as well as all of the combo 120V electrical/USB/C outlets. It took a bit of time to find decent dimmer switches.

Bamboo arrived

View attachment 907966View attachment 907967

Plumbing

View attachment 907970

I finished designing and sizing everything left on the plumbing system(s) and ordered all of the remaining parts . It took a bit of time, but I think every single plumbing item on the fresh water side is not only potable water rated, but also NSF 61 Certified. Trust me, this was a process to ensure every single fitting, hose, gasket, part, etc. was NSF 61 Certified. I will be using PEX A on the hot/cold water.

More expensive composite materials. This is the no joking around super duty epoxy adhesive/hardener for setting/bonding threaded inserts in the composite walls. This applies mostly to inserts needed for mounting L-Track

View attachment 907969

Interior Shower Walls

View attachment 907968

I needed to build out the shower walls about 5/8", to overlap the shower pan. I had some 3/4" Divinycell Core Foam left over, so I decided to have it plained down to 5/8" (Upper left in the above pic). Pretty expensive material to use for building out a shower wall, but it was cheaper to plain down what I had vs. buying some other material. In addition, it will be super light weight, add to the R value in the bathroom (exterior walls) and it's a marine grade material where you need it most.

I'm also going to use left over 1/2" CF composite panels for the floor in the gear locker. I need to build the floor up because I will have recessed L-Track in it. Another opportunity to keep things light and use marine grade material anywhere I can.

Can you post a link to the outdoor white/amber light? I might look at it for my build.

Look forward to seeing you use the super duty epoxy for inserts. Since I am using foam insulation, curious if this is something I can use to build anchor points.

Vance Vanz

Well-known member

Just saw this ITTOG, didn't get an email when you posted your question  .

.

Here is the link for the light

Was going to go with Baja or Rigids for the exterior, but when I found these, they solved the problem of not needing two separate light fixtures to get a white and amber light. I will also use a dimmer on each light within the single fixture.

Almost forgot. The only thing that sucks related to these lights is they don't come with a foamed-backed gasket. I bought some foam gasket sheet material and will be making my own.

related to these lights is they don't come with a foamed-backed gasket. I bought some foam gasket sheet material and will be making my own.

Not sure how much load you will have on each of your anchor points. For my application (threaded insert for mounting L-Track), I will handle it the same way the boating/yachting world does. After drilling a hole in the composite skin (hole size needed for the associated threaded insert), I will ream out the core foam about a 1/2"-5/8" larger in diameter than the drilled hole (using an allen wrench in the end of a drill). Clean out the reamed hole, squirt some toughened epoxy in, thread the insert in, clean up excess pooky and let it cure.

I'm also going to use this same toughened epoxy for bonding a few of my vertical bamboo cabinet pieces to the carbon fiber floor/walls of the camper.

Here is the link for the light

Was going to go with Baja or Rigids for the exterior, but when I found these, they solved the problem of not needing two separate light fixtures to get a white and amber light. I will also use a dimmer on each light within the single fixture.

Almost forgot. The only thing that sucks

Not sure how much load you will have on each of your anchor points. For my application (threaded insert for mounting L-Track), I will handle it the same way the boating/yachting world does. After drilling a hole in the composite skin (hole size needed for the associated threaded insert), I will ream out the core foam about a 1/2"-5/8" larger in diameter than the drilled hole (using an allen wrench in the end of a drill). Clean out the reamed hole, squirt some toughened epoxy in, thread the insert in, clean up excess pooky and let it cure.

I'm also going to use this same toughened epoxy for bonding a few of my vertical bamboo cabinet pieces to the carbon fiber floor/walls of the camper.

Vance Vanz

Well-known member

Slide Out Solar Panel Rack/Arrays - Fabrication & Construction

I had a little lag in the Rear Bumper/Camper Assembly, so I decided to move onto the sliding solar panel arrays to fill in the gap. I knew finishing the fabrication for them and getting them built, for the first time, was going to be a process. Not to mention a great opportunity to test my patience !

!

Getting my head on straight again related to the design. It had been awhile since I originally designed everything. Erin is also getting her hands dirty on the project....... . Gotta Love It!

. Gotta Love It!

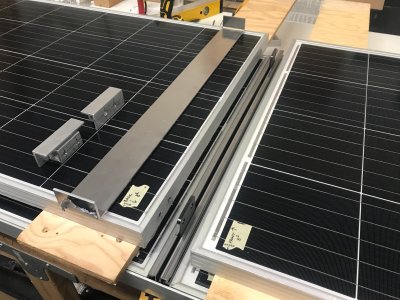

First step was getting the mounting feet on the slide rails. I have a cover cap on the leading/tail edge of the arrays, for the slides, to help keep dirt/debris out of the tracks/bearings.

Getting everything squared up and marked. These are the center mounting feet which attach to back to back slides.

This is when the tedious tasks start to unfold . Grinding down screws so the slides can clear . There were LOTS of these.

. There were LOTS of these.

Moving onto mounting one of the electric linear actuators and also figuring out how I want to secure a piece of angle to the bottom side and face of the solar panel. The angle will act as the structural tie that will fix both of the lower solar panels together.

This is the lower section of the two-panel-array (Drivers side of the truck/camper). The lower sections of the arrays slide and the upper sections are fixed.

I had a little lag in the Rear Bumper/Camper Assembly, so I decided to move onto the sliding solar panel arrays to fill in the gap. I knew finishing the fabrication for them and getting them built, for the first time, was going to be a process. Not to mention a great opportunity to test my patience

Getting my head on straight again related to the design. It had been awhile since I originally designed everything. Erin is also getting her hands dirty on the project.......

First step was getting the mounting feet on the slide rails. I have a cover cap on the leading/tail edge of the arrays, for the slides, to help keep dirt/debris out of the tracks/bearings.

Getting everything squared up and marked. These are the center mounting feet which attach to back to back slides.

This is when the tedious tasks start to unfold . Grinding down screws so the slides can clear

Moving onto mounting one of the electric linear actuators and also figuring out how I want to secure a piece of angle to the bottom side and face of the solar panel. The angle will act as the structural tie that will fix both of the lower solar panels together.

This is the lower section of the two-panel-array (Drivers side of the truck/camper). The lower sections of the arrays slide and the upper sections are fixed.

Vance Vanz

Well-known member

Slide Out Solar Panel Rack/Arrays - Fabrication & Construction - Continued......

Now it's time to move onto the upper section of the two-panel-array .

.

Getting all of the structural spacers cut and pre-drilled.

My DIY ghetto machine shop in action. I needed to make sure that all four parts of the structural spacers lined up perfectly and they also had to line up with the holes in the mounting foot.

Spacing, lining up and drilling holes in the upper panels, so the outside edges could be through bolted to the mounting feet.

Back to the center to get the structural spacers dialed in and to also get the holes in the cover cap laid out and drilled.

I'll spare you all the details of how many times I had to construct and deconstruct all of these items to get to this point. Let's also not forget the number of times I had to flip and spin the array .

.

It doesn't look like much, but this was a process. This was also the easy part . Getting the chain guide track brackets dialed, PV and linear actuator electrical wires all routed/sorted and the two roof entry glands laid out was the real challenge

. Getting the chain guide track brackets dialed, PV and linear actuator electrical wires all routed/sorted and the two roof entry glands laid out was the real challenge  .

.

Now it's time to move onto the upper section of the two-panel-array

Getting all of the structural spacers cut and pre-drilled.

My DIY ghetto machine shop in action. I needed to make sure that all four parts of the structural spacers lined up perfectly and they also had to line up with the holes in the mounting foot.

Spacing, lining up and drilling holes in the upper panels, so the outside edges could be through bolted to the mounting feet.

Back to the center to get the structural spacers dialed in and to also get the holes in the cover cap laid out and drilled.

I'll spare you all the details of how many times I had to construct and deconstruct all of these items to get to this point. Let's also not forget the number of times I had to flip and spin the array

It doesn't look like much, but this was a process. This was also the easy part

Vance Vanz

Well-known member

Slide Out Solar Panel Rack/Arrays - Fabrication & Construction - Continued......

Upper chain guide track brackets (For both driver and passenger side arrays) and some Oh So Fun teensy weensy spacers .

.

Getting one mounted for the drivers side two-panel-array.

Dry fitting the lower chain guide track and checking operation of everything by fully sliding the lower panels.

This is the leading edge of the chain guide track brackets (Upper & Lower) for the PV wires. I designed it so very little, almost none, of the chain cable and PV wires will be exposed to the wind from the leading edge of the camper. No floppy woppy wires on the roof or broken chain cable from the wind. The roof entry gland for these wires also sits directly in front of the right side of the lower chain guide track. Details matter !

!

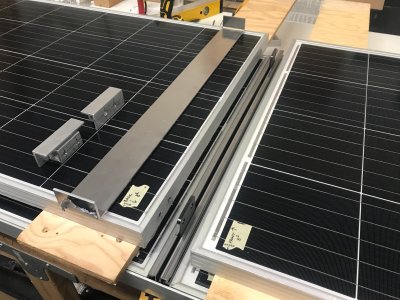

Structural reinforcements for the center of the panels, more spacers and some backing plates

In addition to re-sealing the bottom side of the solar panels to the factory frames, I also added an additional center structural support/tie on each of the ten solar panels. A bit of a time sucker, but well worth it.

Figuring out how and where all of the wires will be ran so all wire mounts can be drilled/installed prior to the final installation.

Next step is pulling this thing apart (AGAIN) and getting it on the roof. Once on the roof: the layout will be finalized, mounting feet holes will be marked, the roof entry gland locations will be finalized and the second actuator will be dialed in (in conjunction with the L Track for the surf board racks).

FYI, each Array will have two linear actuators driving them. The drivers side array is about 10'L and the passenger about 15'L.

More fun to come, stay tuned

Upper chain guide track brackets (For both driver and passenger side arrays) and some Oh So Fun teensy weensy spacers

Getting one mounted for the drivers side two-panel-array.

Dry fitting the lower chain guide track and checking operation of everything by fully sliding the lower panels.

This is the leading edge of the chain guide track brackets (Upper & Lower) for the PV wires. I designed it so very little, almost none, of the chain cable and PV wires will be exposed to the wind from the leading edge of the camper. No floppy woppy wires on the roof or broken chain cable from the wind. The roof entry gland for these wires also sits directly in front of the right side of the lower chain guide track. Details matter

Structural reinforcements for the center of the panels, more spacers and some backing plates

In addition to re-sealing the bottom side of the solar panels to the factory frames, I also added an additional center structural support/tie on each of the ten solar panels. A bit of a time sucker, but well worth it.

Because my mounting feet are on the very ends of the solar panels, as opposed to the sides, I have a longer than normal span between the mounting feet. This is why I wanted the added structural tie.

Figuring out how and where all of the wires will be ran so all wire mounts can be drilled/installed prior to the final installation.

Next step is pulling this thing apart (AGAIN) and getting it on the roof. Once on the roof: the layout will be finalized, mounting feet holes will be marked, the roof entry gland locations will be finalized and the second actuator will be dialed in (in conjunction with the L Track for the surf board racks).

FYI, each Array will have two linear actuators driving them. The drivers side array is about 10'L and the passenger about 15'L.

More fun to come, stay tuned

Last edited:

Vance Vanz

Well-known member

Slide Out Solar Panel Rack/Arrays - Dry Fit on Roof

Got everything put together, the layout finalized and now it is time to start marking holes.

Dialing in the roof entry gland locations.

Pulling everything off the roof. The last look at the drivers side array before final install.

Drilling lots of holes, too many !

!

It's good to see that the LINEX adhesion to the roof is solid, even after putting a holes saw through it.

Intelligent moments by Vance . If you ever change out the bag and filter in your shop vac and it still seems to be a bit off, try running something through the hose.

. If you ever change out the bag and filter in your shop vac and it still seems to be a bit off, try running something through the hose.

You will most likely find a very important item that you may have been blaming someone else for losing . Mine happen to be the end of my vacuum attachment system. The screw on end/adaptor that can easily fall off and they don't sell an individual replacement for (you have to buy a whole new vacuum kit if you lose it). I was Super Excited to find this little bugger. I may also have had to apologize to a certain someone called Erin

. Mine happen to be the end of my vacuum attachment system. The screw on end/adaptor that can easily fall off and they don't sell an individual replacement for (you have to buy a whole new vacuum kit if you lose it). I was Super Excited to find this little bugger. I may also have had to apologize to a certain someone called Erin  .

.

Time to move onto the passenger side.

Got everything put together, the layout finalized and now it is time to start marking holes.

Dialing in the roof entry gland locations.

Pulling everything off the roof. The last look at the drivers side array before final install.

FYI: The area between the back of the skylight and the front of the AC unit, in addition to the area directly in front of this array, will be our roof sitting area. Not huge, but still big enough for two adults to have breakfast, coffee, a cocktail, etc. I spend a lot of time chillin on the roof in my belay chair  . The remainder of the roof will be jam packed/spoken for (unless the surfboards come off, then there is plenty of room to sprawl out.)

. The remainder of the roof will be jam packed/spoken for (unless the surfboards come off, then there is plenty of room to sprawl out.)

Drilling lots of holes, too many

It's good to see that the LINEX adhesion to the roof is solid, even after putting a holes saw through it.

Intelligent moments by Vance

You will most likely find a very important item that you may have been blaming someone else for losing

Time to move onto the passenger side.

Vance Vanz

Well-known member

Slide Out Solar Panel Rack/Arrays - Dry Fit on Roof - Continued......

The fabrication and construction for the passenger side solar rack/array was very similar to that of the drivers side, for the most part. As a result, I'll spare you most of the details and keep it short and sweet.

More DIY machine shop in action for the upper rack center structural spacers.

Because this rack is roughly 15'L, and my shop table is no where near that, I had to build two thirds of the rack, on each end, separately. This meant a lot of putting things together, taking them apart and then putting them together again, just to take them apart again .

.

Getting the roof prepped for dry fit

All dialed in and just enough room to squeeze the Starlink in.

So what do I have to show for all of this hard work .......?

You guessed it, an empty roof .

.

This is the hardest part of the build. It wears on you, spending so much time designing/engineering, part sourcing, fabricating, constructing, dry fitting, adjusting and then pulling it all apart just to put it back on the shelf until powder coat is complete and the build schedule/build process is ready for the final install.

Years of building parts and systems that are still not installed on this thing. BONKERS .

.

The fabrication and construction for the passenger side solar rack/array was very similar to that of the drivers side, for the most part. As a result, I'll spare you most of the details and keep it short and sweet.

More DIY machine shop in action for the upper rack center structural spacers.

Because this rack is roughly 15'L, and my shop table is no where near that, I had to build two thirds of the rack, on each end, separately. This meant a lot of putting things together, taking them apart and then putting them together again, just to take them apart again

Getting the roof prepped for dry fit

All dialed in and just enough room to squeeze the Starlink in.

So what do I have to show for all of this hard work .......?

You guessed it, an empty roof

This is the hardest part of the build. It wears on you, spending so much time designing/engineering, part sourcing, fabricating, constructing, dry fitting, adjusting and then pulling it all apart just to put it back on the shelf until powder coat is complete and the build schedule/build process is ready for the final install.

Years of building parts and systems that are still not installed on this thing. BONKERS

Vance Vanz

Well-known member

Starlink

May be helpful info if you need to flat mount Starlink, with the lengthwise side (longest side) facing into the leading edge of the camper (into the wind), you don't want it removable (will remain fixed on your rig) and you are looking for a quality roof entry gland that will fit/pass the connector on the end of the Starlink antenna wire through it (without cutting the end off).

Short rant before I begin : The toughest initial part of Starlink for me is the mount is more expensive than Starlink. I paid more for my mount ($261) than I did for the Stralink system ($224). How is a piece of UV rated plastic more expensive than the entire Starlink system? And yes, I bought one of the cheaper mounts (not cheap in quality, just price).

: The toughest initial part of Starlink for me is the mount is more expensive than Starlink. I paid more for my mount ($261) than I did for the Stralink system ($224). How is a piece of UV rated plastic more expensive than the entire Starlink system? And yes, I bought one of the cheaper mounts (not cheap in quality, just price).

Moving on .

.

I found a mount from Veritas Vans that used to be $99, but they bumped their price up to $199. Tried it, but the fitment of the frame on the Starlink antenna was wonky and the bottom of the antenna also touched the top of the roof. Wouldn't recommend it.

I then moved onto the next best option for the price/quality, Trio Flatmount. Nothing special, but it will do the job.

It's a little taller than I wanted 2", but that became a benefit for mounting the roof entry gland underneath the mount. It will look much cleaner and the mount/antenna will be an extra layer of water proofing for the entry gland. The antenna wire will also have a short run to the entry gland, so I wont need a wire support (clean and simple).

I you are willing to do a little modification to the Scanstrut roof entry gland, you can get the the connector on the end of the antenna wire to pass through it.

Removed the logo (I'm not a logo guy, trying to remove all logos on the build).

The roof of the camper is dialed and ready for final install, just need to get the mounting feet for the solar arrays powder coated.

Time to move back to the rear bumper/camper assembly.

Next up, spare tire carrier (a real head scratcher and tester of patience).

(a real head scratcher and tester of patience).

May be helpful info if you need to flat mount Starlink, with the lengthwise side (longest side) facing into the leading edge of the camper (into the wind), you don't want it removable (will remain fixed on your rig) and you are looking for a quality roof entry gland that will fit/pass the connector on the end of the Starlink antenna wire through it (without cutting the end off).

Short rant before I begin

Moving on

I found a mount from Veritas Vans that used to be $99, but they bumped their price up to $199. Tried it, but the fitment of the frame on the Starlink antenna was wonky and the bottom of the antenna also touched the top of the roof. Wouldn't recommend it.

I then moved onto the next best option for the price/quality, Trio Flatmount. Nothing special, but it will do the job.

It's a little taller than I wanted 2", but that became a benefit for mounting the roof entry gland underneath the mount. It will look much cleaner and the mount/antenna will be an extra layer of water proofing for the entry gland. The antenna wire will also have a short run to the entry gland, so I wont need a wire support (clean and simple).

I you are willing to do a little modification to the Scanstrut roof entry gland, you can get the the connector on the end of the antenna wire to pass through it.

Removed the logo (I'm not a logo guy, trying to remove all logos on the build).

They provide two notches in the bottom of the frame for passing the antenna wire under the mount, but no drain holes in the bottom of the frame that make sense given the design. I added five small strategically located drain holes, on the non-leading edge sides x 3, so this thing can drain/air out (No mold or skunky slime building up under the mount for me please  ).

).

The roof of the camper is dialed and ready for final install, just need to get the mounting feet for the solar arrays powder coated.

Time to move back to the rear bumper/camper assembly.

Next up, spare tire carrier

Last edited:

Given your skills, I'm surprised you didn't just fabricate your own flat mount and save quite a few bucks. Not sure what your final mounting will look like, but FYI, you'll definitely want to figure out a way to add in a slight tilt. I originally mounted my dish totally flat, and found that a hard rain would cause pooling and disrupt the signal in fairly short order. Modifying it to have a few degrees of tilt totally eliminated the issue though.

Similar threads

- Replies

- 6

- Views

- 296

- Replies

- 5

- Views

- 1K

- Replies

- 3

- Views

- 844

- Replies

- 3

- Views

- 2K