My wife and I have this thing where we could go out and buy the thing we want and then use it and be happy but we always seems to choose the path with the highest amount of ass pain. When we had our house built we could have gone out to IKEA and plunked down cash on the barrel for a turn key kitchen. Instead, we cut down standing Doug Fir trees on our property, bucked and stacked the logs, milled them bitches, dried them for a couple years, jointed, planed and hand-built our kitchen cabinets out of our own lumber. We love our kitchen but holy ********, there's an easier path. We didn't learn our lesson. We taking that same path with this camper. We bought an empty shell and we're building out the interior, including the casework, electrical and plumbing systems because... reasons. At least this time, we're gonna buy the damned wood.

We looked at a lot of campers and man, there is some good campers on the market. We really like OEV and Alterra. FWC campers are great but pop-up campers always felt like being in a tent. We wanted a hard-side camper. We already know how tall it will be. We already know how top heavy it will be. Every decision we make in this build is trading one thing for another. We're optimizing for comfort at camp.

We really liked the form factor of Total Composites campers. Love the four season utility of the well insulated walls and how light they are. We looked at quite a few builders but once we met Quade from

Overland Adventure Truck it was a pretty easy decision. Quade was so easy to work with and accommodated all of our custom dimensions. He's been doing this longer than most and really understands the build process.

Last summer, OAT switched their manufacturing from TC panels over to

Cascadia Composites. The reasons Quade gave me was that the new panels are tougher (I got to beat the ******** out of sample in his shop with a hammer and didn't even make a mark) and higher R value. They are manufactured in Canada so they aren't subject to oceanic shipping and Chinese tariffs (although Canadian tariffs might become a thing soon). Plus, they aren't bright white so the camper doesn't look like a soda delivery truck. We put a deposit down at Overland Expo PNW in June and picked up the camper in December.

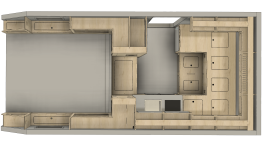

View attachment 870746

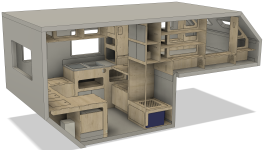

View attachment 870747

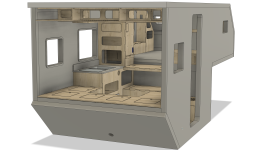

View attachment 870748

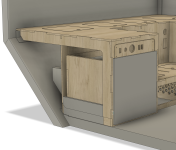

View attachment 870749

Doing some story stick measuring of the camper interior dimensions to create an "as-built" 3D model

View attachment 870750

View attachment 870751

Our asspain of a kitchen made from our own trees...

View attachment 870752