1x1_Speed_Craig

Active member

I'm first addressing the biggest priorities with my M101A3 trailer (wiring, coupler swap/mods, etc.), I want to give some thought to, and start researching, the future air bag suspension design. I already have a set of AT mounts, and should have some air bags shortly (currently a backorder issue...hopefully getting an update soon).

Given my intended use for the trailer (mainly road, with some light offroad), I have zero interest in getting into the complexities of scratch-building an independent trailing arm suspension set-up (I might consider it if I could just buy the kit from AT, but a retrofit by them isn't an option due mainly to geography, and also by cost). I'm not confident that I could get the alignment correct given the tools/knowledge I have. So, my intentions are to use a standard trailer axle from ABC Trailer Parts, and:

For the latter option, I have searched extensively here, and am looking for specific recommendations on:

Parts/component selection:

Questions:

Discuss, please, and enlighten me. :sombrero:

Craig

Given my intended use for the trailer (mainly road, with some light offroad), I have zero interest in getting into the complexities of scratch-building an independent trailing arm suspension set-up (I might consider it if I could just buy the kit from AT, but a retrofit by them isn't an option due mainly to geography, and also by cost). I'm not confident that I could get the alignment correct given the tools/knowledge I have. So, my intentions are to use a standard trailer axle from ABC Trailer Parts, and:

- Use the main leaf spring from the stock suspension (removing all other leaves) to locate the axle. I'll do this if there's adequate clearance, as it'll be the simplest approach.

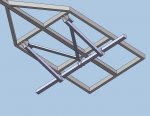

*OR* - Build a 3-link set-up.

For the latter option, I have searched extensively here, and am looking for specific recommendations on:

- 3-link design (e.g. - THIS THREAD was very helpful)

- Product/component suggestions

Parts/component selection:

- BTF link mounts, or something similar. I have ordered from BTF before, and like their stuff.

- 2" or 2 1/2" Johnny Joint on the frame end. The stock M101A3 spring hanger has a ~2 1/4" ID, so the 2" model would work well for width. I thought I could use the existing leaf spring hanger to mount the front Johnny Joint, but I'll have to see what diameter main eye bolt the stock leaves use. The 2" JJ only uses a 7/16" bolt (too small, I believe), while the 2 1/2" JJ (which is 2 5/8" wide) uses a 9/16" bolt. A custom hanger bracket may be required regardless, but I'd really like to retain the stock hanger, as the tongue mounting bracket is also integrated into the stock cast spring hanger bracket (translation = simplicity).

- Panhard bar with poly bushings on both ends. I could make one, or just use an off-the-shelf trac bar from a Jeep or other application, and could use these BTF mounting brackets.

- Use the stock shocks already on the M101A3.

Questions:

- Is 22-24" long enough for the trailing arm links?

- Are there any real downsides to a 3-link on a trailer with this intended use?

- What may I be overlooking with the design ideas?

Discuss, please, and enlighten me. :sombrero:

Craig