Check this build....

http://www.pirate4x4.com/forum/desert-racing/1082739-filarskis-xj-pre-runner-build.html

Need to build them tough when you drive like this...

[video=youtube;4dU9M055RlU]http://www.youtube.com/watch?feature=player_embedded&v=4dU9M055RlU[/video]

Same guys built this F-150...

http://www.expeditionportal.com/for...ity-F150-Pre-runner-Expo-build?highlight=f150

Without excessive lift, you're going to have to do a lot of trimming to get 35's under an XJ, the problem with the 4-doors is the rear doors start getting in the way of the trimming. Curious what a "mini stroker" is?

Ya I saw that race out here actually. The filarski(sp?) bros. And a mini stroker is a bit to understand but very very easy if your mechanically inclined. Stock 4.0 pistons run a 1.60x pin height, off the shelfs at best are a 1.592 and range down to 1.582. So a stock 4.0 rebuild with off the shelf pistons puts your pistons further down, which gives a worse quench height and potentially less compression, thus less performance. The 4.0 stock stroke is 3.410. The pistons are already .02x-.03x in the whole from the factory, then adding the difference of off the shelf pistons gives you .04x-.05x.

A mini strokers heart is its crank. It's a 3.500" stroke crank from a 3.8l amc. Not popular but very useful in certain cases and gain popularity very quickly. It's got a .09" bigger stroke than the stock 4.0. You take half that, because the pistons are sitting above the crank..so the top "half". Which is .045". Remember you stock 4.0 pistons already .02-.03 in the hole? When adding off the shelf pistons your .04-.05 in the hole. So using this crank gives you a zero deck basically pending what pistons you actually use. I used the tallest which were 1.592 pin height. Did that because i wanted the tightest quench possible, the tightest to date is .017 in a stock rpm(5300) without any issue. My pistons sit above the deck by .013. My quench heigh is .029 compare to the stock .0745. The head gasket is .043 - .013 because my pistons are above deck, giving .030-.029 quench. It'll be much more efficient. My compression is 9.4:1 static, and 8.1:1 dynamic. Stock is 8.8:1 static, 7.4:1 dynamic. I'm using a stock cam and 1.7 roller rockers. It's quite a bit more efficient than the stock 4.0. Definitely stronger, and gets more mileage on 87. It actually gets better mileage on 91 than 87 because its been tuned to run a bit leaner, makes a bit more power. The gain in mileage vs adding cost kinda makes it a wash, fillinng with 91 actually saves me a few pennies and nets me more power which is felt just by switching the tune. Filling with 91 over 87 is like 5 bucks per tank..really unnoticeable, but in the case I can't get 91 while out exploring small old towns or incase someone has a jerry can with 87, then no worries she's happy on 87 and still stronger than a stock 4.0. Ported head, ls6 valves & other stuff are playing a part here, ALOT cam down to spending the money on great parts vs good parts. 1 key thing is lifters & timing sets. Comps cam savers have reports of dying without reason. I run Johnson/hytech brand. And the timing set, everyone goes to cloyes because the dual roller which is "ok" but still has a cast sprocket, so you not really fixing anything with it..I run the "roll master cs7100" which is truelly billet at both ends and it cost less than the cloyes & is still a dual roller Stronger & cheaper.

The bigger stroke & stock bore is actually 4.05L, .030 over is 4.1, .060 over is a 4.2l. .060 over also un-shrouds the valve producing better flow and a more efficient burn. It's all around better. When you get into it bearings and turning a 4.0 crank is like 250 bucks & to achieve a zero deck youll have to deck the block which is another 100-175! You can pick up this 3.500" crank from clegg performance WITH bearings for like 230 to your door I believe. Even if its 350 its worth it because you'll have a bigger stroke, not much but still, and achieve a zero deck with off the shelf pistons.

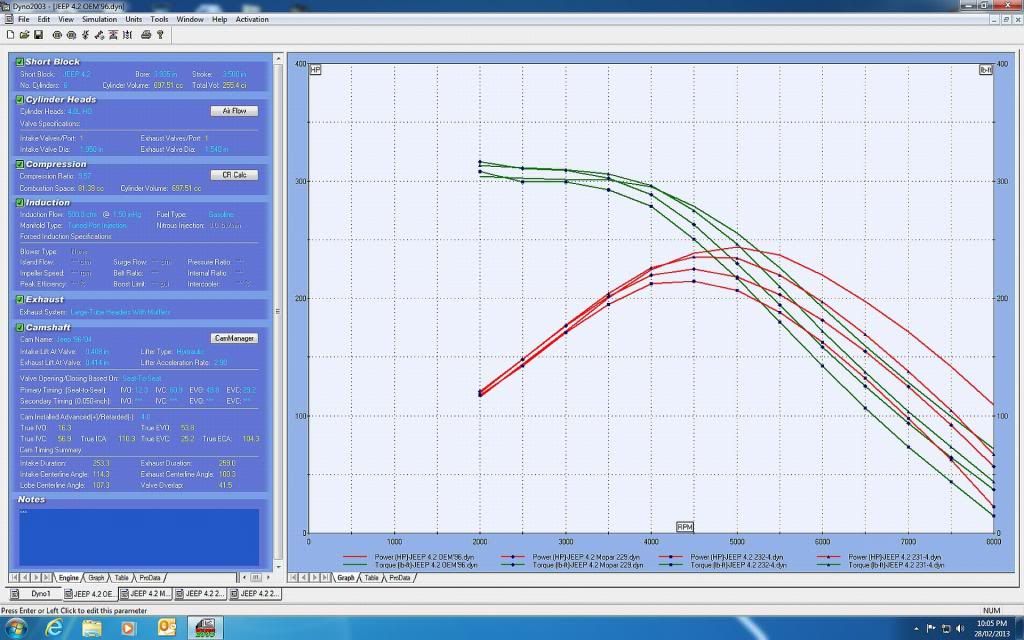

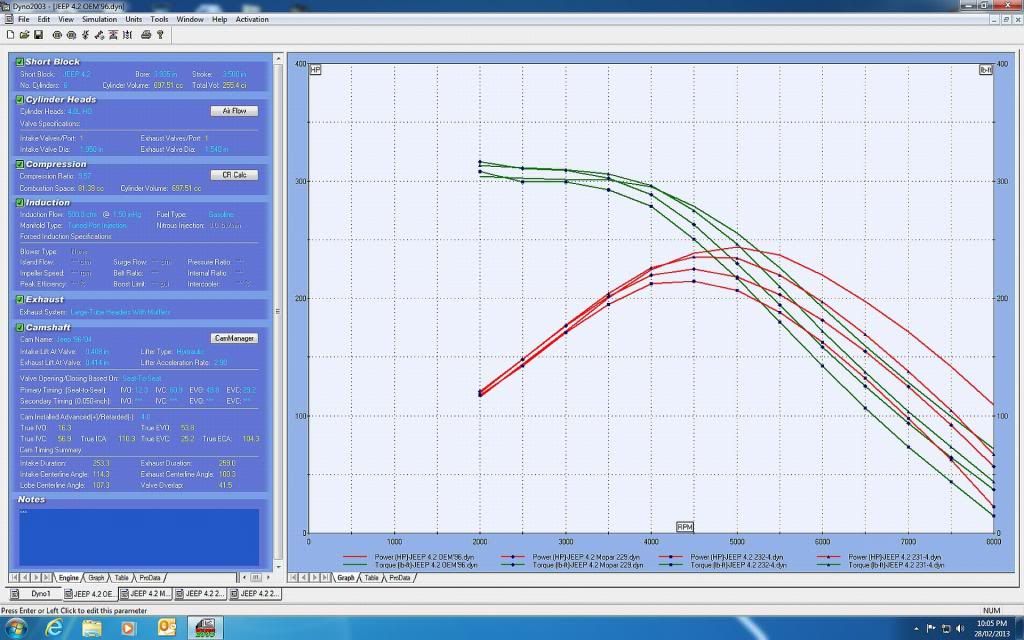

On a simulated dyno that matches a stock 4.0 in the curve and power output, down to head flow & valve size, quench, cc sizes and posts on disk, bore clearances ect ect. Pretty darn technical program, it was spot on for the stock 4.0 in output. Swapped in my specs such as head flow numbers, valve size, piston dish & cc size...here are the results.

I compared against all the cams that everyone liked. I hate the comp cams..skinny lobes and too many failures have been reported. Plus the mopar 229 is better than the comp 232 with considerably less lift and duration. The mopar 229 is a wide lobe like stock and can be run on stock valve train, the 232 is past stock valve train limits. Anyway I'm running the 96-99 stock cam, stock cams had different variations and specs, this is the best! I advanced it 4* to gain a little low end. You can see at 2000-4000rpm the stock cam is 100% flat..incredible? These "torque cams" offered just aren't worth the risk of a cam failure or added cost of new valve springs and such. I mean look at the difference, I see maybe 20ftlbs, and that's at the crank. If you really needed or wanted a cam the mopar 229 wins and can be run on stock valve train with no worries. The difference is so little though, your better off buying the Yella Tera 1.7 rockers. they bolt on in a few short hours and fit under the tock valve cover with no issues! And for power the comp 232 is lowest, followed by the mopar 229, then the comp 231, then the stock 96-99 cam advanced 4*. If you look close enough the stock cam actually peaks higher than the rest at 3500rpm by a few ponies as well.

The reason for the advance on the stock was because it would carry power to 5600rpm where it was unuseable. The 4* advance brought the peak right to 5000rpm. Our redline is 5250 & it brought up some more low end & mid range power

advancing it more showed no gains, and actually slight loses in certain areas. My guess is I make around 225hp & over 300ft lbs at the crank. Total cost was around 3000, again including the ported head and super light weight/sodium filled ls6 valve train and spending extra on certain parts that preform better (lifters & timing set) and the Yella Tera 1.7 roller rockers were $418. Without all that I'd be around 1800 or so for a full quality rebuild.

And I'm trimmed up already, had 35s before, although for a short time. There's quite a few rigs on basic 3" lifts running 35s. I sit around 4" front 4.5 rear with the deavers and stock shackle. It would clear 35s if I made that choice. This is my close friend & go to fab guy now. He's on 39.5" irons, 60/14b. They measure around 40" actual. He's at 71.5" at the drip rail. He sits lower than me and I'm on 33s lol. I'm at 72.5-74" at the drip rail. Deffinetly no worries to chop it up a bit.

My jeep getting welded on. Installing HD offroad no lift relocators, his in the back ground.