dustboy

Explorer

So I have this nice 14" Jet 1 HP bandsaw, all set up with Carter BB guides and a Kreg fence system. Cuts wood like a champ, square and straight.

Then I started doing a lot of metalwork on my rig. I can cut a lot of stuff with my chopsaw and jig saw, but that's a drag. It would be sweet to cut metal with this fancy bandsaw..only problem is the blade moves waaay too fast. Like 3300 IPM, when mild steel wants to cut at around 300 IPM (correction invited). I don't have the space or money for a horizontal saw.

I did try just putting a 14 TPI metal blade on it and using some cutting oil, which worked for more cuts than I expected, but after the teeth started breaking off it got progressively harder to cut.

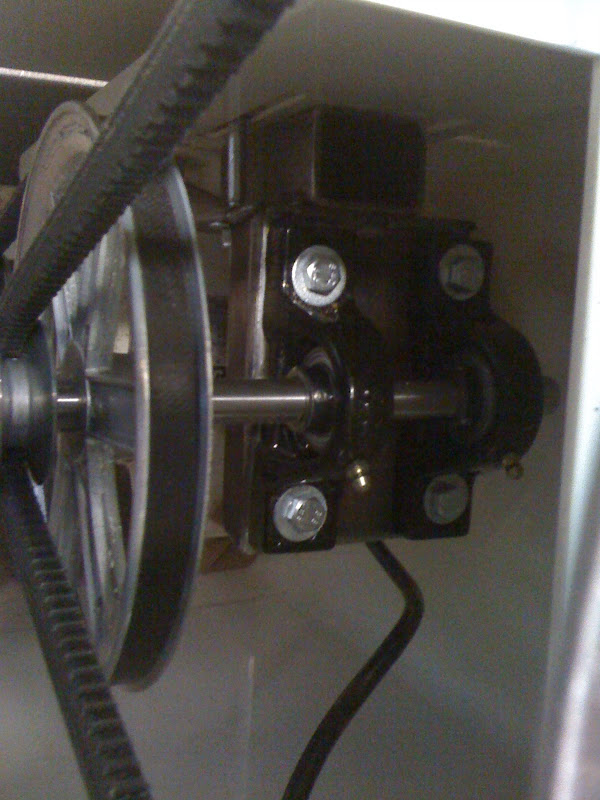

So, slow the thing down. To get enough reduction I will need to add a jackshaft, and even then there isn't enough room to get a ratio of more than 14:1 compared to the original 2.4:1.

I'll spare you the math, but it looks like I can get the blade speed down to 561 IPM. And I'll add a coolant mister just in case.

The plan:

Motor: original 2.5" pulley

Jackshaft: 7" pulley to 2" pulley

Drive shaft: 10" pulley (originally 6")

I just ordered the parts from McMaster-Carr. Here is the list:

1 1 Each 6245K953 Die Cast V-Belt Pulley 4L, A-, & Ax Section Belt, 10" OD, 3/4" Bore $23.21

2 1 Each 6245K16 Die Cast V-Belt Pulley 4L, A-, & Ax Section Belt, 2" OD, 5/8" Bore $3.25

3 1 Each 6245K53 Die Cast V-Belt Pulley 4L, A-, & Ax-Section Belt, 7" OD, 5/8" Bore $11.50

4 1 Each 1497K108 Fully Keyed 1045 Steel Drive Shaft 5/8" OD, 3/16" Keyway Width, 9" Length $17.73

5 2 Each 6244K52

Cast Iron Base-Mounted Steel Ball Bearing Set-Screw Lock, for 5/8" Shaft Diameter $33.67

6 1 Each 11365K63

Biodegradable Misting Coolant Concentrate Kool Mist 78, 1-Gallon Container $29.48

Total $152.51

Stay tuned, I plan to put it together this weekend and I'll post the results. Oh, BTW Jet does sell a speed reduction kit for this saw, but it only gets it down to 750 IPM, which I figured was still too fast.

Then I started doing a lot of metalwork on my rig. I can cut a lot of stuff with my chopsaw and jig saw, but that's a drag. It would be sweet to cut metal with this fancy bandsaw..only problem is the blade moves waaay too fast. Like 3300 IPM, when mild steel wants to cut at around 300 IPM (correction invited). I don't have the space or money for a horizontal saw.

I did try just putting a 14 TPI metal blade on it and using some cutting oil, which worked for more cuts than I expected, but after the teeth started breaking off it got progressively harder to cut.

So, slow the thing down. To get enough reduction I will need to add a jackshaft, and even then there isn't enough room to get a ratio of more than 14:1 compared to the original 2.4:1.

I'll spare you the math, but it looks like I can get the blade speed down to 561 IPM. And I'll add a coolant mister just in case.

The plan:

Motor: original 2.5" pulley

Jackshaft: 7" pulley to 2" pulley

Drive shaft: 10" pulley (originally 6")

I just ordered the parts from McMaster-Carr. Here is the list:

1 1 Each 6245K953 Die Cast V-Belt Pulley 4L, A-, & Ax Section Belt, 10" OD, 3/4" Bore $23.21

2 1 Each 6245K16 Die Cast V-Belt Pulley 4L, A-, & Ax Section Belt, 2" OD, 5/8" Bore $3.25

3 1 Each 6245K53 Die Cast V-Belt Pulley 4L, A-, & Ax-Section Belt, 7" OD, 5/8" Bore $11.50

4 1 Each 1497K108 Fully Keyed 1045 Steel Drive Shaft 5/8" OD, 3/16" Keyway Width, 9" Length $17.73

5 2 Each 6244K52

Cast Iron Base-Mounted Steel Ball Bearing Set-Screw Lock, for 5/8" Shaft Diameter $33.67

6 1 Each 11365K63

Biodegradable Misting Coolant Concentrate Kool Mist 78, 1-Gallon Container $29.48

Total $152.51

Stay tuned, I plan to put it together this weekend and I'll post the results. Oh, BTW Jet does sell a speed reduction kit for this saw, but it only gets it down to 750 IPM, which I figured was still too fast.