You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Broke and striped rocker bolts (LR3)

- Thread starter TexasTJ

- Start date

krick3tt

Adventurer

Is it possible to remove part of the slider (under the vehicle) that covers the compressor to allow for R&R without taking off the slider. You would have to do that part once you have removed the slider to replace the bolt and have the broken stud drilled and the hole tapped for new bolt. At least it would not vibrate and it would then be fully functional as a slider again.

My sliders do not go under the vehicle as much as yours seem to so it was not a problem for me to have the compressor replaced. I have an LR3 so I had the compressor that is used on LR4 model installed as I was informed it was a more robust piece of machinery.

My sliders do not go under the vehicle as much as yours seem to so it was not a problem for me to have the compressor replaced. I have an LR3 so I had the compressor that is used on LR4 model installed as I was informed it was a more robust piece of machinery.

morrisdl

Adventurer

you could, but (if i am understanding you) it would no longer protect the compressor. this is important protection to me. Over the past 11 years...mine has several scars there that would have demolished the air suspension. I just had mine off to reshape that section back to allow clearance. I saw a similar vintage RRS that relocated and upgraded to the AMK compressor in the 2nd battery bay as another option.

krick3tt

Adventurer

Good to hear it is going well. Perhaps the protection of the compressor is worth the aggravation of having to replace a bolt to two.

There is a video by AB that shows some things under the LR3 and RRS (same stuff under there) https://www.roverparts.com/resources/videos/undercarriage-tour-for-lr3/

Good to check it out for possible other parts that may need to locate.

There is a video by AB that shows some things under the LR3 and RRS (same stuff under there) https://www.roverparts.com/resources/videos/undercarriage-tour-for-lr3/

Good to check it out for possible other parts that may need to locate.

Last edited:

Victory_Overland

Explorer

With the bolt out I was able to retap the rear most hole to 5/16 and get the slider back on last night. I sill may later drill out the rear hole and Install a larger Nutsert, but this will work for now.

How many were broken and/or stripped? If it's just one, I wouldn't mess anymore with it after you clean up the threads with the tap. Keep in mind, if those are stainless (I can't tell) they are much more brittle than Grade 8 bolts. Stainless obviously has a better corrosion prevention but not the strength so there is a tradeoff only you can decide.

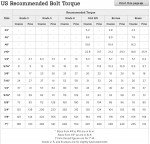

Add some blue Loctite on install and apply a sufficient amount of torque and leave it. 5/16" general bolt is gonna be around 110-150 in/lb or so depending on thread pitch and construct. Not saying you need a torque wrench for every bolt, but sometimes we forget that tighter is not always better. If you run this bolt back in and it holds torque to spec, leave it!

Here's a good general hardware chart! I use an aviation one but this one will get you in the ballpark for all your hardware needs but if you want a specific metric one, let me know and I'll post it up when I get home. You can convert the size from standard to metric to get you in the ballpark.

Sucks they snapped your bolts off but it's great to hear you were able to fix the issue.

Attachments

DiscoDavis

Explorer

one thing I picked up from swiss mechanic friend was if a bolt is one that needs to come off for access, repair, service, coat it in copper slip (or nickel slip). I have yet to have one rotate itself loose or off, and there are exceptions, but it fixes the issue with broken bolts