DiploStrat

Expedition Leader

16? Kid has a career!

Bravo! (Oh, and the camper ain't too shabby either.)

Bravo! (Oh, and the camper ain't too shabby either.)

Hi!

Just re-read the entire thread for the third time, it took a week...

Still an amazing build and log, with excellent info, thanks!

Are you still using it, or have you moved forward on your new designs?

Any update on long term use of different components and durability would be highly appreciated, like did the brush seals hold up? are the slides still as good? all your thoughts on cabinet doors, are you still satisfied with your choices? what is your biggest mistake or regret in your design?

Thanks again for sharing your adventure in both build and use!

16? Kid has a career!

Bravo! (Oh, and the camper ain't too shabby either.)

Thanks Christian, glad it's still worthwhile reading. I still use it frequently, and overall it's held up very well. The brush seals have done OK, but I should've chosen a finer fiber so it would have less memory. I have to "fluff" the fibers at camp sometimes. The slides have held up decent as well. The side slides, which use the LCI mechanisms have jammed a few times, I think from getting off track when bouncing down super rough roads. Some prodding gets the teeth back in the tracks. The big custom rams that drive the big slide room continue to work just fine, but I'm probably going to take them apart this winter and check the acme drive components.

I used Reico Titan motors for those rams, as well as for the corner lifting jacks, and I've had to replace three of the six units in 6 years. I'll also be rebuilding the corner lifting jacks this winter, with beefier screws with less pitch (will require less lifting force with more revolutions, slower lift).

The cabinets have done fine, a few of the plastic catches from the locking knobs have either worn down from use and vibration or cracked, but they're easy to replace.

I've repaired cracks in my black water tank three times, so I finally just had a new one built using 3/8" material with more internal baffles and support, as well as several external support ribs to remove stress on the area where it kept failing.

As for the biggest mistake in my design? Probably just a bit too tall. But from a design perspective, I'm still very happy with the rig and its super functional. My mistakes were more on the engineering and construction side, but that just lends to the "personality" of a one-off!

My next rig has been built in CAD, I'm finalizing infrastructure component decisions and hoping to get the work started on the chassis in October. The body is designed to fit on a flat bed. The big difference in the new build is size and maneuverability- My needs are way different now, so I need something that can travel fast and light, yet still be comfortable in camp. In travel mode, the "camper" box is 7.5' wide, 6' tall, and 12' long. It expands to almost 200 sqft of living space with 6'10" ceiling height in about 45 seconds using a single actuator. On a NPR crew cab (converted to 4x4) chassis, curb weight will be just about 5 tons fully loaded. Should be a fun project, looking forward to starting a new build thread soon.

Thanks! He's now 18 and doing amazing work. Hopefully he can support me one day!

I am curious how you are achieving the square footage increase from driving to camping. Please elaborate.

Loved the last build. Looking forward to the next one.

Sent from my iPad using Tapatalk

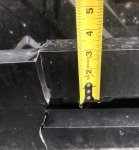

Back on the road, Uinta Mountains, Utah. Everything was fine until I sheared the coupler pin on one of my leveling jacks getting ready to leave. I've been putting off installing hydraulic leveling jacks on the chassis since I bought it, but it's long over due. The electric jacks just can't get the job done on uneven terrain.View attachment 600014