Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Composite fiberglass/foam panel build question

- Thread starter VerMonsterRV

- Start date

rruff

Explorer

Certainly find some links if you can.

FRP has proven over the years to be very tough to bond to. Most FRPs are epoxy based polymers, but it still takes a pretty rough FRP surface to provide enough for the epoxy to grab.

https://www.swaylocks.com/forums/xpsglassingdelamination

http://forum.surfer.com/forum/ubbthreads.php?ubb=showflat&Number=2145290

http://shedtech.blogspot.com/2014/12/

Pretty sure the FG skins are using polyester resin and gelcoat rather than epoxy.

rruff

Explorer

I myself love the glass over foam method, but it is extremely labor intensive compared too a composite core panel

It certainly can! It depends on how much you care about a smooth, flat surface. If you want it to look "factory" perfect (and you would, since you are building for others) it takes a huge amount of work. All that fairing and sanding.

The way I'm doing it though, isn't a lot of work. I'm hoping a texture coat will keep it from being too ugly

stomperxj

Explorer

After looking at this page:

http://shedtech.blogspot.com/2014/12/

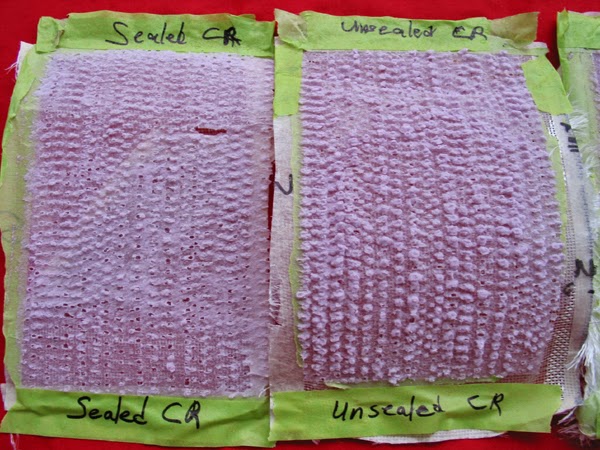

The carpet roller treatment keyed the adhesive into the foam quite well. I'm encouraged by that.

http://shedtech.blogspot.com/2014/12/

The carpet roller treatment keyed the adhesive into the foam quite well. I'm encouraged by that.

rruff

Explorer

The carpet roller treatment keyed the adhesive into the foam quite well. I'm encouraged by that.

The dog brush is working better for me anyway. More consistent as well.

IdaSHO

IDACAMPER

https://www.swaylocks.com/forums/xpsglassingdelamination

http://forum.surfer.com/forum/ubbthreads.php?ubb=showflat&Number=2145290

http://shedtech.blogspot.com/2014/12/

Pretty sure the FG skins are using polyester resin and gelcoat rather than epoxy.

Interesting links, but I fail to see how this negates the use of epoxy.

The problems were not the epoxy, the problems that folks have had are due to the gassing of the foam.

They were also 100% related to glassing XPS with epoxy and matt/cloth, not using epoxy as an adhesive between a foam core and a skin.

There isnt much reason to reinvent the wheel. The Australian and European panel manufacturers are using some version of pu adhesives, moisture, 2 part or hot melt, depending on their manufacturing lines. FRP and planed XPS and it works. Just find which type of adhesives works best for YOU and go with it. Plenty of them use vacuum bagging, which is fairly inexpensive and easy to use. I think moisture cured is the easiest to work with so thats what I use. Personally the set time for epoxy is the turn off for me.

stomperxj

Explorer

Id be interested in comparing your urethane with an actual panel adhesive that Epic Resins carries.

Ad also be interested in their explanation as to why they suggested this potting urethane instead of an actual panel adhesive, that they also carry.

I spoke with my Epic rep the other day. The panel adhesive they have is for structural insulated panels for commercial/residential that are stationary. It is Shore D 80 hardness.

rruff

Explorer

I think moisture cured is the easiest to work with so thats what I use. Personally the set time for epoxy is the turn off for me.

How well does that work when you have two surfaces that are nearly impermeable to moisture (XPS and FRP)?

Set time for epoxy... I guess it can take ~24hrs to acheive full strength at room temp, if you use the slow cure stuff. Is that what you mean?

Correct rruff. With the moisture cures I can have 20-90min of set up time and less than 90 minutes press time. Temperature dependent. Epoxy will certainly work and is easy to use and used by plenty of folks. For me I just think the moisture or 2 parts are better simply because of the time. Being able to do more than one panel per day is essential for me.

stoneburner

New member

Hello,

I did the XPS peel panel blog at the link rruf posted:

After seeing this thread I updated the blog.

01 January 2018

It has been a few years. In retrospect, I abandoned the sealer. It filled the roughed peaks and valleys without adding any apparent improved bonding with epoxy.

I liked the Topflite Woodpecker tool best. Perforation is more about increasing surface area for bonding – many smaller holes/cuts would bond better than fewer big holes. The big holes add more resin weight. In my testing, the stock Woodpecker tool (WPT) seemed as effective as, or more so than, the carpet roller and appeared to use less resin (lighter?). I modified the Woodpecker tool, adding more tynes -- photos below -- to increase perforation numbers and total surface area for resin penetration/bonding. I had planned to use the modified WPT for a late summer-autumn build this year. But several issues postponed that project.

BTW because XPS is a closed-cell foam (less than 0.1% water absorption by volume), there is no outgassing. There are several surfboard epoxy resins readily available for use. The bonding problem with epoxy is related to the minimal penetration of resin into the very "thin layer" of small cells -- ruptured by sanding -- on the XPS surface.

Bill

Modified WPT top, standard bottom.

I did the XPS peel panel blog at the link rruf posted:

After seeing this thread I updated the blog.

01 January 2018

It has been a few years. In retrospect, I abandoned the sealer. It filled the roughed peaks and valleys without adding any apparent improved bonding with epoxy.

I liked the Topflite Woodpecker tool best. Perforation is more about increasing surface area for bonding – many smaller holes/cuts would bond better than fewer big holes. The big holes add more resin weight. In my testing, the stock Woodpecker tool (WPT) seemed as effective as, or more so than, the carpet roller and appeared to use less resin (lighter?). I modified the Woodpecker tool, adding more tynes -- photos below -- to increase perforation numbers and total surface area for resin penetration/bonding. I had planned to use the modified WPT for a late summer-autumn build this year. But several issues postponed that project.

BTW because XPS is a closed-cell foam (less than 0.1% water absorption by volume), there is no outgassing. There are several surfboard epoxy resins readily available for use. The bonding problem with epoxy is related to the minimal penetration of resin into the very "thin layer" of small cells -- ruptured by sanding -- on the XPS surface.

Bill

Modified WPT top, standard bottom.

Last edited:

Victorian

Approved Vendor : Total Composites

You made some good points about the XPS. There is a reason 99% of all expedition trucks (and commercial bodies) are constructed with the PU foam core.

Another option to gain maximum strength would be a PP honeycomb core, but you would certainly compromise the insulation value.

I believe most private people use the XPS because it's easy to find. Where PU foam is more of a challenge to get your hands on.

Another option to gain maximum strength would be a PP honeycomb core, but you would certainly compromise the insulation value.

I believe most private people use the XPS because it's easy to find. Where PU foam is more of a challenge to get your hands on.

rruff

Explorer

You made some good points about the XPS. There is a reason 99% of all expedition trucks (and commercial bodies) are constructed with the PU foam core.

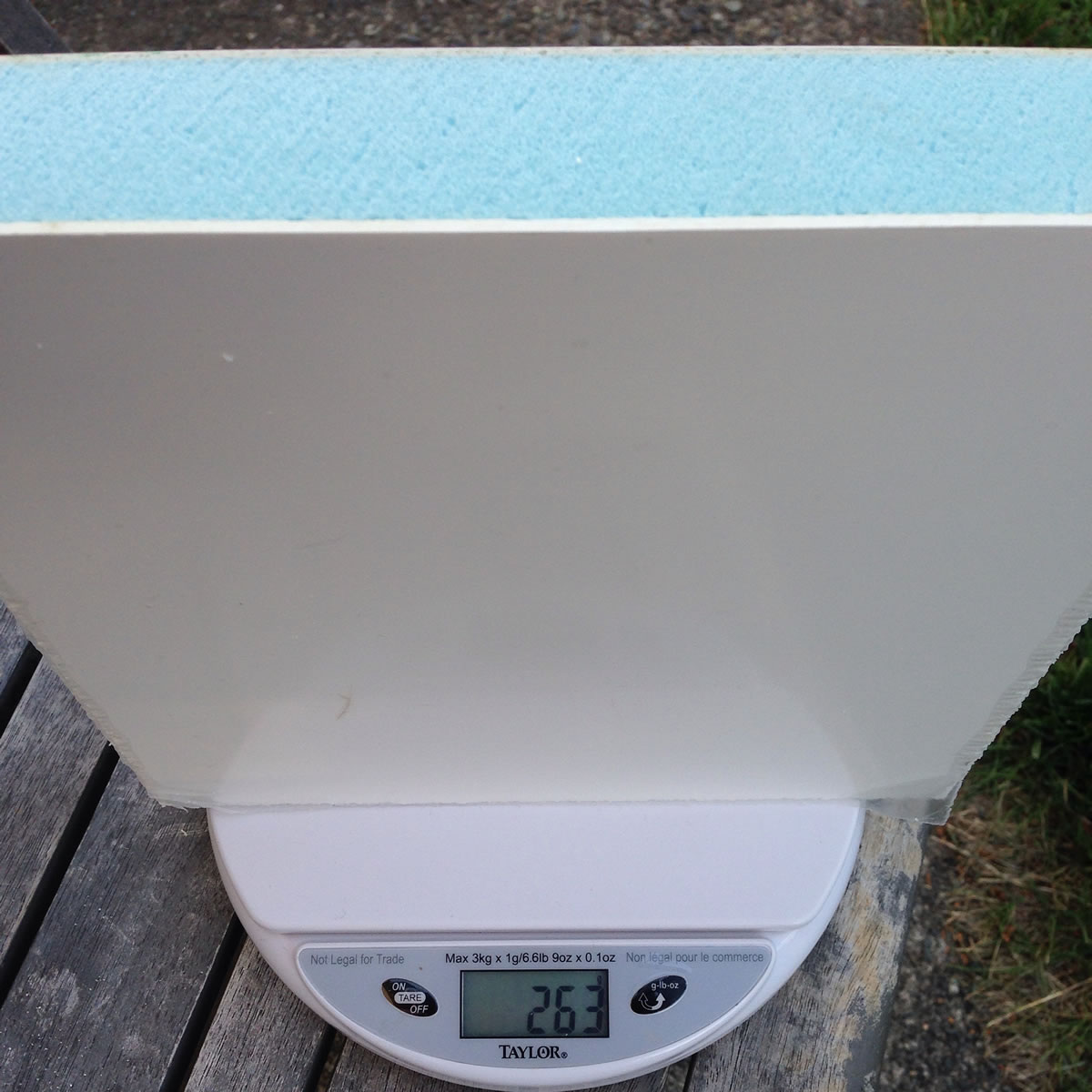

Isn't this XPS?

stoneburner

New member

Hard to tell just by looking.Isn't this XPS?

If it is Dow insulation foam it is XPS (extruded polystyrene).

Dow XPS insulation is blue and Owens-Corning is pink.

stoneburner

New member

The advantages of Polyurethane foam (PU) are that it can be molded. And it has better heat resistance and is more porous than XPS. The density of molded PU is not uniform, being more dense at the surface -- a disadvantage if you over sand. PU also soaks up water.You made some good points about the XPS. There is a reason 99% of all expedition trucks (and commercial bodies) are constructed with the PU foam core.

Another option to gain maximum strength would be a PP honeycomb core, but you would certainly compromise the insulation value.

I believe most private people use the XPS because it's easy to find. Where PU foam is more of a challenge to get your hands on.

The advantage of XPS is that does not soak up moisture and foam density is uniform.

EPS (expanded polystyrene) has channels between the fused beads. Epoxy can penetrate. But EPS soads up water. EPS has relatively uniform density also.

Bonding for all of these foams is affected by density and minimum compressive strength. With low minimum compressive strength, the foam crushes easily, eventually leading to delamination.

_____

Last edited:

Similar threads

- Replies

- 9

- Views

- 321

- Replies

- 51

- Views

- 9K

- Replies

- 2

- Views

- 1K

- Replies

- 5

- Views

- 289