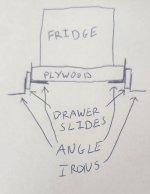

I'm getting started on a DIY fridge slide build for my van. I have some drawer slides on the way, and need to decide if 1/16" aluminum angle iron is sufficient or if should go up to 1/8" thick angle iron.

My fridge is an older ARB 50 qt - weighs 53 lbs, plus I figure another 80 lbs if it were to be stuffed full of drinks.

My fridge is an older ARB 50 qt - weighs 53 lbs, plus I figure another 80 lbs if it were to be stuffed full of drinks.