MrGrodskyi

New member

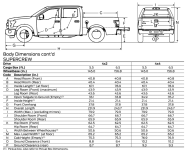

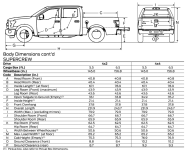

Hi, I am starting to build my soft pop up camper for a 1/2-ton truck with 6`5`` bed. (Perhaps a hard side in the future).

I want to share my design and plans, and maybe get some criticism on how to improve.

Design:

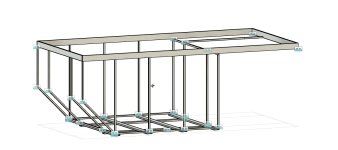

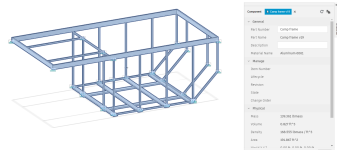

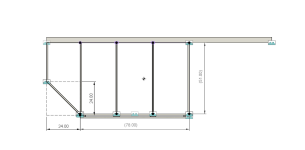

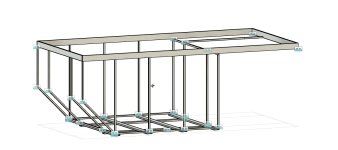

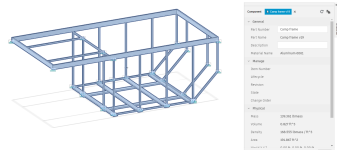

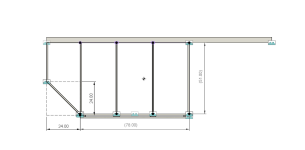

I am trying to make something close to this design. I won't have a special bed. Direct attachment to the frame, through something that will allow the frame to flex.

I planned to use 1x1 and 1x4 square aluminum tubing with 1/8 wall. I plan to use rivets to fasten the frame. Also, add steel or aluminum bars over the joint (since these are square pipes and they do not intersect.

External and internal sheathing should be made of AСM. For gluing the panels I will use Sikaflex and possibly rivets, adding modding from an aluminum half-square at the joints.

For insulation, I will use 1 inch of Extruded Polystyrene from Home Depot in the walls (between the aluminum tubes) + 0.5 inch on top to cover the aluminum tubes.

But recently I heard the opinion that a steel square 3/4 x 3/4 1/16 has only slightly more mass (0.6lbs/ft) than an aluminum square 1x1 1/8 (0.52lbs/ft). It got me thinking.

Using steel I can weld it without any problems, also without using extra plates which also add weight.

Also by using steel, I think I will be able to reduce the size of the square at the top of the bed which will also reduce the weight.

The steel is also 50% cheaper compared to 6061

So I see a lot of upside to using steel, and only a small downside, possibly adding 10%-15% weight.

I am critical of the weight as it is only a 1/2-ton truck. But I think it's worth it. What is your opinion?

Should I be concerned about the contact of aluminum panels with steel?

Theoretically, the glue should separate them.

Should I be worried about moisture in the steel and rust? I don't plan on this camper for 30 years. But would not like to get rust after 1-2 years.

To be continued....)

I want to share my design and plans, and maybe get some criticism on how to improve.

Design:

I am trying to make something close to this design. I won't have a special bed. Direct attachment to the frame, through something that will allow the frame to flex.

I planned to use 1x1 and 1x4 square aluminum tubing with 1/8 wall. I plan to use rivets to fasten the frame. Also, add steel or aluminum bars over the joint (since these are square pipes and they do not intersect.

External and internal sheathing should be made of AСM. For gluing the panels I will use Sikaflex and possibly rivets, adding modding from an aluminum half-square at the joints.

For insulation, I will use 1 inch of Extruded Polystyrene from Home Depot in the walls (between the aluminum tubes) + 0.5 inch on top to cover the aluminum tubes.

But recently I heard the opinion that a steel square 3/4 x 3/4 1/16 has only slightly more mass (0.6lbs/ft) than an aluminum square 1x1 1/8 (0.52lbs/ft). It got me thinking.

Using steel I can weld it without any problems, also without using extra plates which also add weight.

Also by using steel, I think I will be able to reduce the size of the square at the top of the bed which will also reduce the weight.

The steel is also 50% cheaper compared to 6061

So I see a lot of upside to using steel, and only a small downside, possibly adding 10%-15% weight.

I am critical of the weight as it is only a 1/2-ton truck. But I think it's worth it. What is your opinion?

Should I be concerned about the contact of aluminum panels with steel?

Theoretically, the glue should separate them.

Should I be worried about moisture in the steel and rust? I don't plan on this camper for 30 years. But would not like to get rust after 1-2 years.

To be continued....)