I'm curious too but 5yrs of use wouldn't be too bad either

I just took the truck for a 18hrs round trip to pick up a 5000lbs ambo box that I'll build up as my camper. I can say that on the way it wasn't that comfortable, bouncy, some vibrations... Then on the way back with the box loaded on the frame it was a delight! Ran way better! And I think I can make it even better.

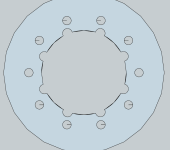

I figured one issue with my rims (and a solution). There's some vibration which seem to be on the front driver side. Either I forgot to add beads to that wheel (unlikely but possible) or the following:

The adapter plate I built (with the 20 outer studs holes) has the same size of stud holes as the main rim which are slightly oversized for the studs size. One the rim it's not an issue as the outer ring self-aligns itself with the inner ring but on my plate there's no such thing. The adapter plate can be bolted a little offset which would cause vibrations. I'm thinking to add 2 dowels between the outer ring and my adapter plate so that all the holes would be perfectly aligned and would stay that way as I tighten the 20 nuts.

Makes sense?

And because a post without pictures is boring... found a little brother in town, lol.

View attachment 779198