Thanks for the idea. I know where to get 1/8 and 1/4 HDPE starboard.

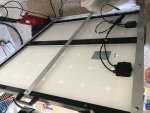

I like the idea.... but I keep looking at this 80/20 glide track and feel like its perfect. I'm hung up right now on how to fasten the rails to the rack, and the glide track to the solar panel frame.

Rack: I think I would through bolt from the bottom side, insert a nut into the front runner slats, and fasten down. I think I would need to drill and counterbore each hole however, and not sure how comfortable I am with that without a drill press. The holes would have to be spaced perfectly. 80/20 offers machining services for access holes, but they only have an option to counterbore the ends. I thought about using side brackets, sounds weaker, and I don't have enough clearance to the sides for 2 of the rack slats due to gutter mount feet.

Glide track: I was thinking flathead stainless screws, however the top portion is only 0.3" across, which would only allow for a ~#8 or M4 screw... which I think is too small. I'd want to at least use a 1/4-20 screw (that has a 0.477" diameter head).

anyone worked with 80/20 before and have tips?

I like the idea.... but I keep looking at this 80/20 glide track and feel like its perfect. I'm hung up right now on how to fasten the rails to the rack, and the glide track to the solar panel frame.

Rack: I think I would through bolt from the bottom side, insert a nut into the front runner slats, and fasten down. I think I would need to drill and counterbore each hole however, and not sure how comfortable I am with that without a drill press. The holes would have to be spaced perfectly. 80/20 offers machining services for access holes, but they only have an option to counterbore the ends. I thought about using side brackets, sounds weaker, and I don't have enough clearance to the sides for 2 of the rack slats due to gutter mount feet.

Glide track: I was thinking flathead stainless screws, however the top portion is only 0.3" across, which would only allow for a ~#8 or M4 screw... which I think is too small. I'd want to at least use a 1/4-20 screw (that has a 0.477" diameter head).

anyone worked with 80/20 before and have tips?