wwpage66

New member

Finally getting around th working on this after all the parts came in. To many other busy weekends, and poor weather here

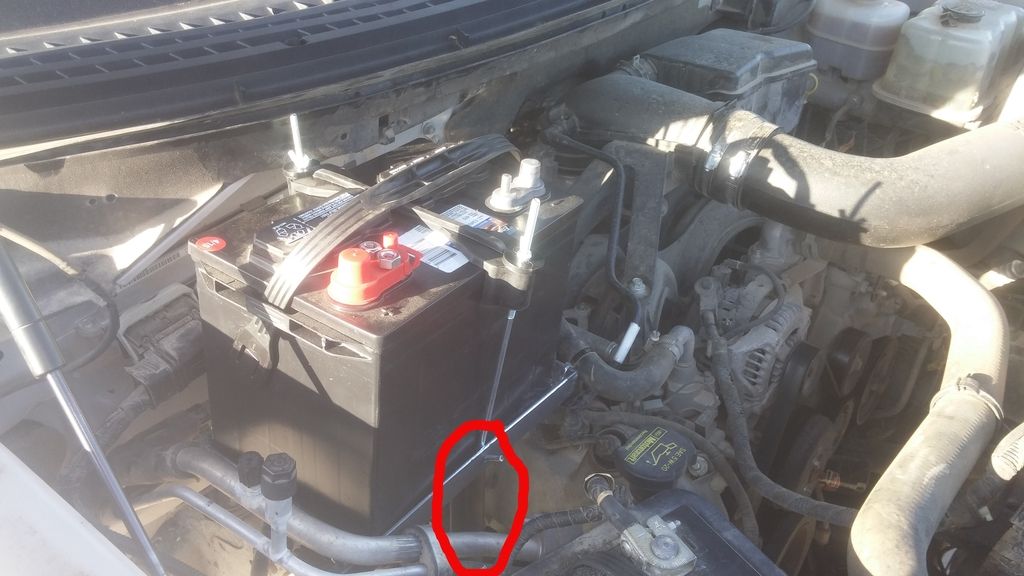

Got the bracket make for the 2nd battery up in the engine compartment. There really is not much room for a 2nd battery up there on a 2010 F150 but finally got it to work, killed my HF cheap welder in the process.

And how it fit in there.

Yes my truck is dirty, it regularly makes trips down dirt road and out on the farm, just not down the forest roads and out west adventures I would prefer.....someday. Until then continue on getting this rig ready.

Put some thin metal on the bottom of my tray to help deflect the heat from the exhaust and then put some reflective insulation on the bottom. Maybe just overthinking it but just seems in a place where it will get too much heat from engine.

The battery on the tray and tied down.

Now to work getting the electric wired up, have a few days before a 4 day weekend.

Got the bracket make for the 2nd battery up in the engine compartment. There really is not much room for a 2nd battery up there on a 2010 F150 but finally got it to work, killed my HF cheap welder in the process.

And how it fit in there.

Yes my truck is dirty, it regularly makes trips down dirt road and out on the farm, just not down the forest roads and out west adventures I would prefer.....someday. Until then continue on getting this rig ready.

Put some thin metal on the bottom of my tray to help deflect the heat from the exhaust and then put some reflective insulation on the bottom. Maybe just overthinking it but just seems in a place where it will get too much heat from engine.

The battery on the tray and tied down.

Now to work getting the electric wired up, have a few days before a 4 day weekend.

Last edited: