Flick's Offroad/Utility Trailer Build

Since this is the forum that I got the inspiration to start a project like this, with NO welding skills I might add, I thought I'd post up some pictures of the process so far.

I've got to give a big thumbs up to my buddy Jason, for the use of his garage, tools, and expertise. Anytime he needs anything I know I'll be there for him.

Who knew that the Jeep would haul steel. Guess that is why it is called a "Utility" vehicle

Squared up frame. Using 2x3 14ga

Axle setup (http://goo.gl/k32N) I went with these just to get the 5x5 bolt pattern that my Jeep has, not for the 3500 lbs.

Mocked up with some 35x12.5" tires mounted

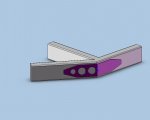

Front tongue started. Installed the receiver stock through the front part of the frame, and tied it to the front cross member.

Thanks to Martyn for the coupler. I could not be happier with it, and everyone that sees it just :drool: at the sight.

Bottom 14ga going on

I didn't get any pictures of it, but there is also some receiver stock going through the back of the frame and to the back cross member. It sticks out less than 1/4".

Since this is the forum that I got the inspiration to start a project like this, with NO welding skills I might add, I thought I'd post up some pictures of the process so far.

I've got to give a big thumbs up to my buddy Jason, for the use of his garage, tools, and expertise. Anytime he needs anything I know I'll be there for him.

Who knew that the Jeep would haul steel. Guess that is why it is called a "Utility" vehicle

Squared up frame. Using 2x3 14ga

Axle setup (http://goo.gl/k32N) I went with these just to get the 5x5 bolt pattern that my Jeep has, not for the 3500 lbs.

Mocked up with some 35x12.5" tires mounted

Front tongue started. Installed the receiver stock through the front part of the frame, and tied it to the front cross member.

Thanks to Martyn for the coupler. I could not be happier with it, and everyone that sees it just :drool: at the sight.

Bottom 14ga going on

I didn't get any pictures of it, but there is also some receiver stock going through the back of the frame and to the back cross member. It sticks out less than 1/4".

Last edited: