You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FRP Composite panels ( US Source)

- Thread starter sprocket3

- Start date

mog

Kodiak Buckaroo

These guys have kits listed for sale Adventure Trucks

I would think they are part of Global Expedition Vehicles as they share the same address and photo number. So perhaps the same panels they use in their GEV habitat building?

Disclaimer - no experience with these panels or company

I would think they are part of Global Expedition Vehicles as they share the same address and photo number. So perhaps the same panels they use in their GEV habitat building?

Disclaimer - no experience with these panels or company

I've wondered out them. Those are the same pics they have had up for a couple years and I vaguely remember someone posting that they weren't able to connect on it. Will be interesting to see if anyone has contacted them recently.These guys have kits listed for sale Adventure Trucks

I would think they are part of Global Expedition Vehicles as they share the same address and photo number. So perhaps the same panels they use in their GEV habitat building?

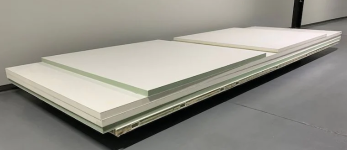

View attachment 805077

View attachment 805078

Disclaimer - no experience with these panels or company

Alloy

Well-known member

Peter_n_Margaret

Adventurer

We have a quality panel supplier in Oz, which must be a tiny market compared with the USA?

www.vanglassrv.com.au

They make and sell caravans of their own design or your design and will supply anything from panels, lock up stage to finished product for any product that the customer wants. Last time I visited, a guy was building a house boat in one of their sheds. The exterior panels were finished in grey gel coat

www.vanglassrv.com.au

They make and sell caravans of their own design or your design and will supply anything from panels, lock up stage to finished product for any product that the customer wants. Last time I visited, a guy was building a house boat in one of their sheds. The exterior panels were finished in grey gel coat

They make their own closed cell polyurethane foam and also have a PET foam specifically for floors.

They make wet-on-wet panels up to 2.5m x 11m in one piece and can then CNC router cut them to any shape required so a kit can be glued together like a KEA flat pack.

I used some of their panels in my build 20 years ago and are using their panels 100% again with my current light weight build.

Cheers,

Peter

OKA196 motorhome

Composite Caravans | Queensland | Vanglass

VLPCaravans - Hi tech composite panel caravans , camper trailers and slide-on campers. Build your own Caravan , camper trailer or slide-ons. Composite fibreglass panels. http://www.vanglassleisureproducts.com.au

www.vanglassrv.com.au

www.vanglassrv.com.au

They make their own closed cell polyurethane foam and also have a PET foam specifically for floors.

They make wet-on-wet panels up to 2.5m x 11m in one piece and can then CNC router cut them to any shape required so a kit can be glued together like a KEA flat pack.

I used some of their panels in my build 20 years ago and are using their panels 100% again with my current light weight build.

Cheers,

Peter

OKA196 motorhome

Alloy

Well-known member

We have a quality panel supplier in Oz, which must be a tiny market compared with the USA?

They make and sell caravans of their own design or your design and will supply anything from panels, lock up stage to finished product for any product that the customer wants. Last time I visited, a guy was building a house boat in one of their sheds. The exterior panels were finished in grey gel coatComposite Caravans | Queensland | Vanglass

VLPCaravans - Hi tech composite panel caravans , camper trailers and slide-on campers. Build your own Caravan , camper trailer or slide-ons. Composite fibreglass panels. http://www.vanglassleisureproducts.com.auwww.vanglassrv.com.au

View attachment 805095

They make their own closed cell polyurethane foam and also have a PET foam specifically for floors.

They make wet-on-wet panels up to 2.5m x 11m in one piece and can then CNC router cut them to any shape required so a kit can be glued together like a KEA flat pack.

I used some of their panels in my build 20 years ago and are using their panels 100% again with my current light weight build.

Cheers,

Peter

OKA196 motorhome

Styromax does vehicles

PU foam used for insulation isn't close (not used below grade) cell and it has thermal drift.

mog

Kodiak Buckaroo

The cabin I have on my C4500 came off of a Unimog that was built with FRP-plywood-foam-plywood-FRP construction. While it is super strong it is also very heavy. 1850 kg for a 365cm long (19 m³) outfitted with interior and equipment. If you have not already checked out @RAM5500 CAMPERTHING thread on his build HERE , he was very creative on his cabinets (along with other innovations.)Thanks guys. I sent off some emails. Got a few leads on panels. I found a place that will make whatever i want in 2000sqft batches. They stated it needed a plywood layer in order to hang cabinets.

Peter_n_Margaret

Adventurer

Wow Sikaflex for the win. I was wondering if a combination of adhesive and short screws would do it. Hate to screw into that finish.

The cabin I have on my C4500 came off of a Unimog that was built with FRP-plywood-foam-plywood-FRP construction. While it is super strong it is also very heavy. 1850 kg for a 365cm long (19 m³) outfitted with interior and equipment. If you have not already checked out @RAM5500 CAMPERTHING thread on his build HERE , he was very creative on his cabinets (along with other innovations.)

View attachment 805253

I'll check it out. Wood seems like going the wrong direction.

Alloy

Well-known member

Thanks guys. I sent off some emails. Got a few leads on panels. I found a place that will make whatever i want in 2000sqft batches. They stated it needed a plywood layer in order to hang cabinets.

How are you folks doing upper cabinets in these foam core builds? 3m tape

The bond between the FRP and the foam is the weak spot. This is why panel mfg will use plwyood/luan but you want to avoid wood that can't (inside the panels) be serviced.

There's options like this.

20+ Years of Composite Board Solutions | The Coosa Board Advantage

Coosa Composites is the top choice when it comes to quality composite boards. Order the most durable composite materials for your next project today!

mog

Kodiak Buckaroo

My 6+ year old Total Composite kit uses wood in the floor for strength (perhaps a holdover from their commercial boxes that would have high impacts and loads).I'll check it out. Wood seems like going the wrong direction.

My style with the plywood under the FRP

BUT perhaps they have found that overkill and no longer use plywood any longer

I'm sure Andres will let us know the pluses or minuses of wood in the floor or other locations (unless that is a trade secret and with me posting these top secret photos I might be 'disappeared'

Victorian

Approved Vendor : Total Composites

My 6+ year old Total Composite kit uses wood in the floor for strength (perhaps a holdover from their commercial boxes that would have high impacts and loads).

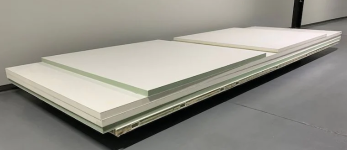

View attachment 805317

My style with the plywood under the FRP

View attachment 805318

BUT perhaps they have found that overkill and no longer use plywood any longer

View attachment 805319

View attachment 805320

I'm sure Andres will let us know the pluses or minuses of wood in the floor or other locations (unless that is a trade secret and with me posting these top secret photos I might be 'disappeared')

LOL. All that info is out there…. No secrets revealed. Most of the images of our construction are just to visualize the concept/idea. Too many outside eyes watching us to post all the details in a public place. There is much more to it than what you see in the pictures above. Each application needs a different solution and therefore it’s nearly impossible to give a straight answer about the exact composition of each panel.

Anyhow, aside from the pictures above, we recently have designed several new FRP profiles (pultrusions) that will further advance our system. In total we now have 9 different FRP pultrusions we are using.

Cheers

Peter_n_Margaret

Adventurer

In my view, avoid screws at all costs. They cause local stress concentrations when they resist differential expansion forces.Wow Sikaflex for the win. I was wondering if a combination of adhesive and short screws would do it. Hate to screw into that finish.

The secrets to adhesive use are: 1) Surface prep, 2) Appropriate primers, 3) Maximise surface area. 4) Appropriate adhesive for the job, 5) Appropriate adhesive thickness to allow for the expected movement / thermal expansions.

Some people make the mistake of only using the strongest/stiffest adhesive that they can find. The higher the tensile of single pack urethanes, the lower the elongation before break.

The best adhesive is the one with the lowest tensile that will do the job because it will have the highest elongation before breaking, which gets back to maximising the surface area.

Cheers,

Peter

OKA196 motorhome

Similar threads

- Replies

- 0

- Views

- 225

- Replies

- 33

- Views

- 4K

- Replies

- 4

- Views

- 2K

- Replies

- 12

- Views

- 7K

- Replies

- 32

- Views

- 5K