dhackney

Expedition Leader

I've been doing some research on replacing the rear section of our FG frame.

I thought this info might be of interest.

Notes:

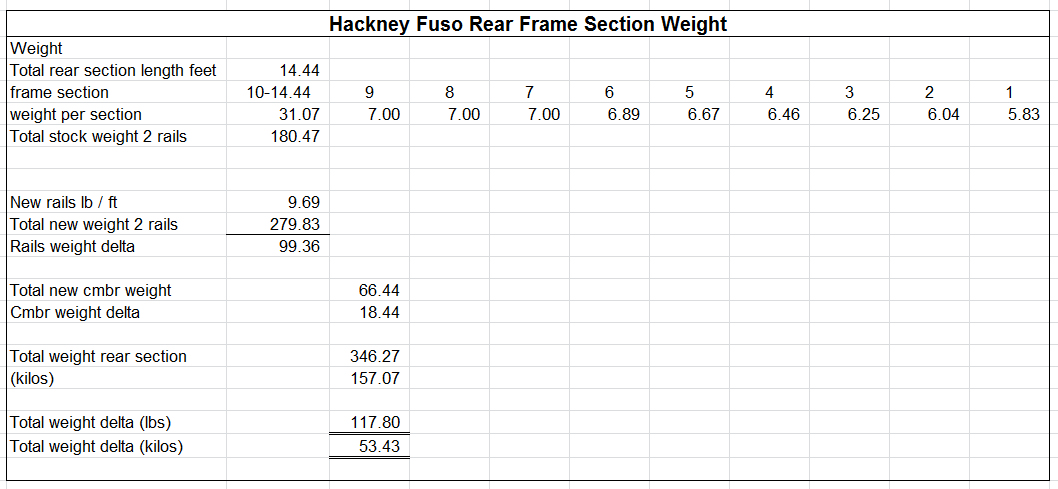

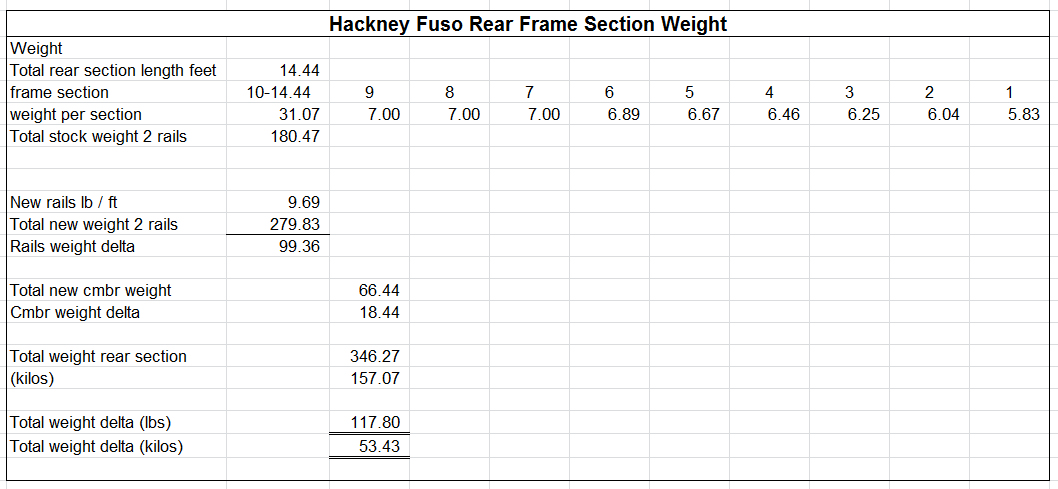

Note that the rear section of our frame is extended, so the weight delta is different from a stock frame.

Info on the frame and crossmembers is here: http://www.hackneys.com/mitsu/docs/fusoframemodificationinfo.pdf

Info on the stock frame modulus is here: http://www.hackneys.com/mitsu/docs/fusoframesectionmodulus.pdf

Info on reinforcing the FG step-down section is here: http://www.hackneys.com/mitsu/docs/fusoframeFGreinforcement.pdf

Replacement frame info is from P.G. Adams http://www.pgadams.com/truckframes.php

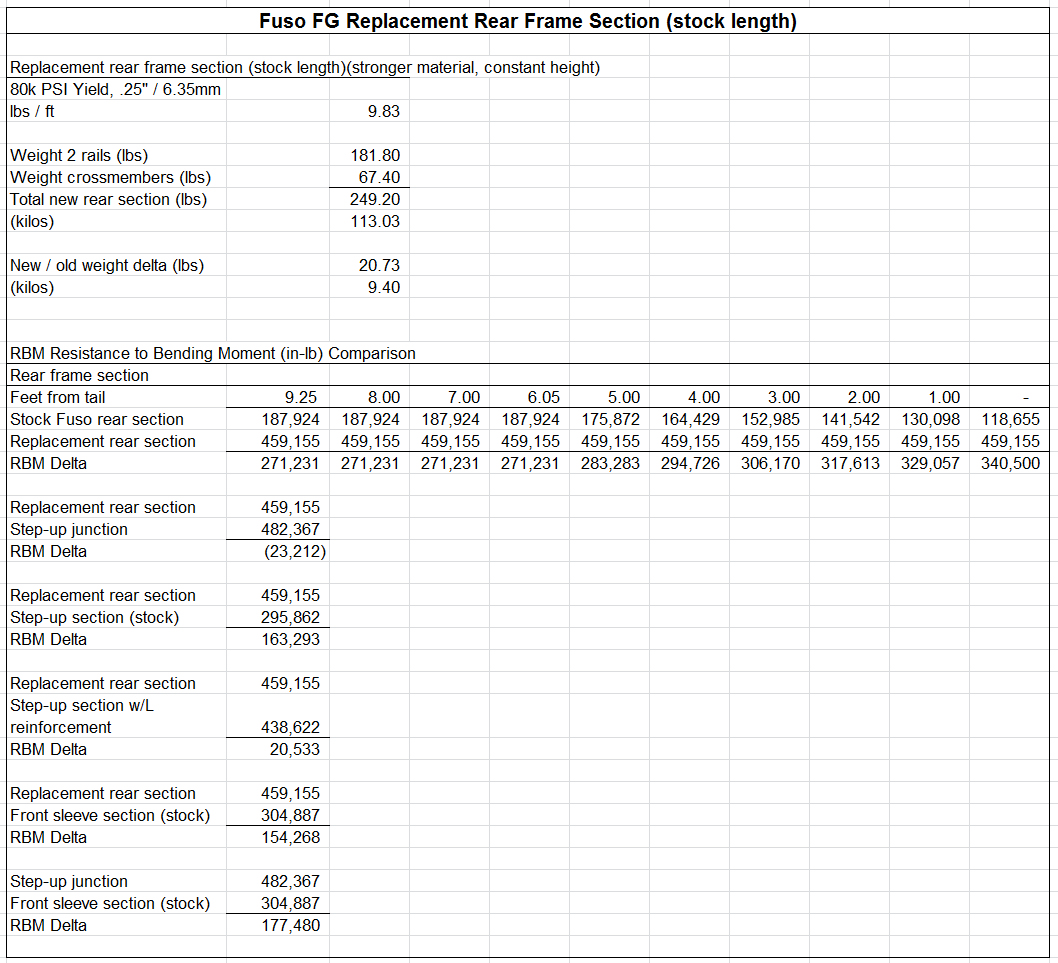

Quoted cost for two 80k PSI rails for our length (longer than stock) is ~$1,600. Cost of drilling holes to match the stock frame varies depending on the number of holes. If you match every hole you can spend as much for the drilling as for the frame rails. (Quote is based on constant height rails with the flanges cut down to match the stock flange width)

The process is to ship them the stock frame section so they can match the holes. They ship the new frame back. Total turnaround is a few weeks including ~two weeks of shipping time. Freight both ways from TX to VT to TX is ~$1,000.

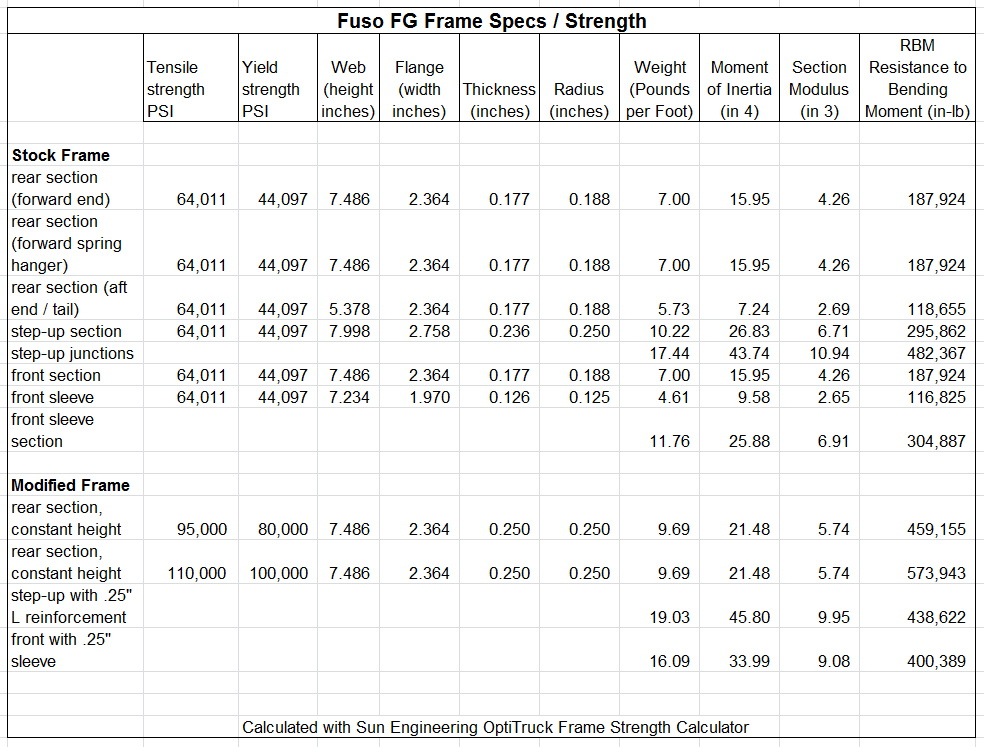

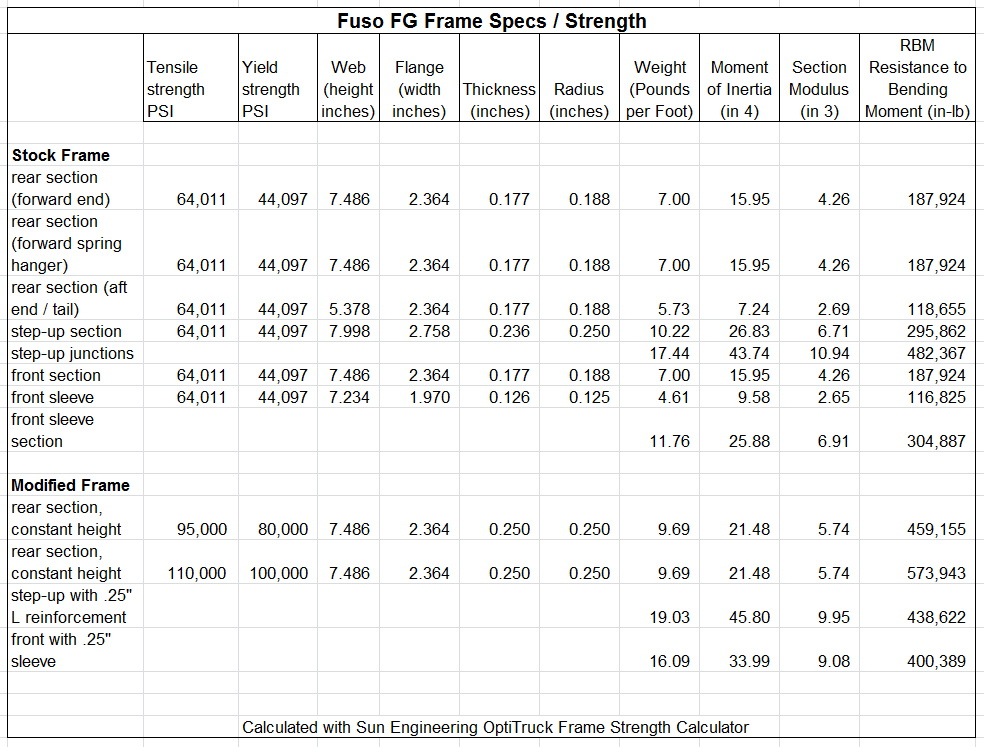

The stock FG frame is C channel.

The stock FG's frame is riveted together at the step-up junctions.

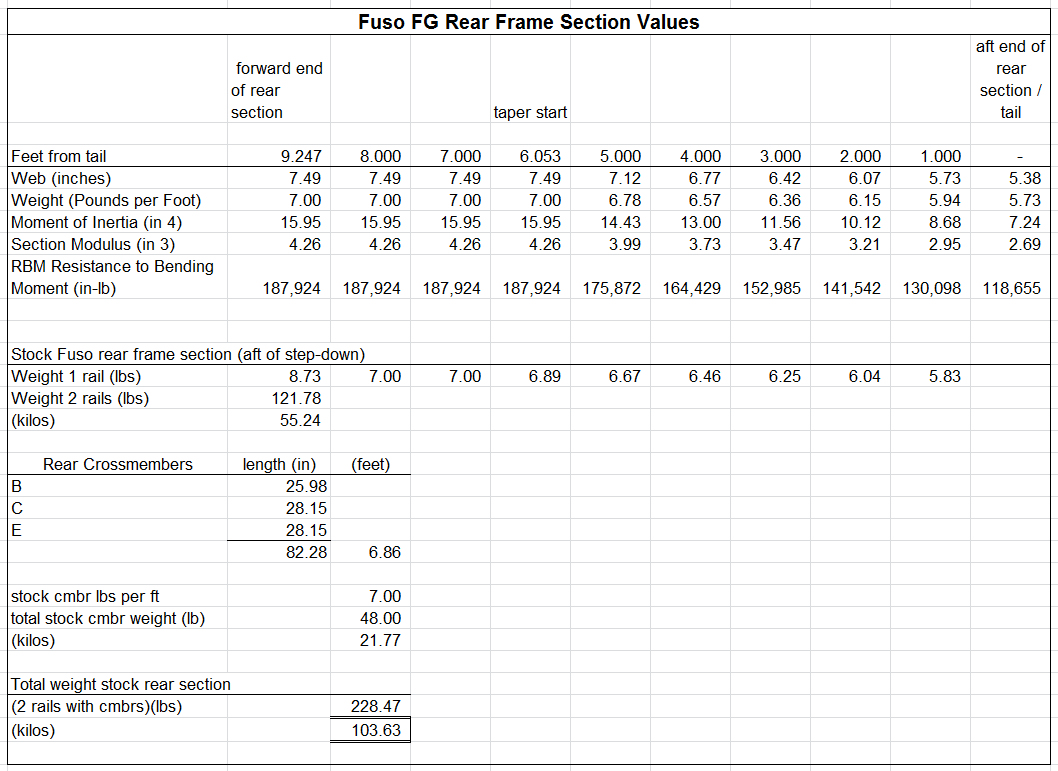

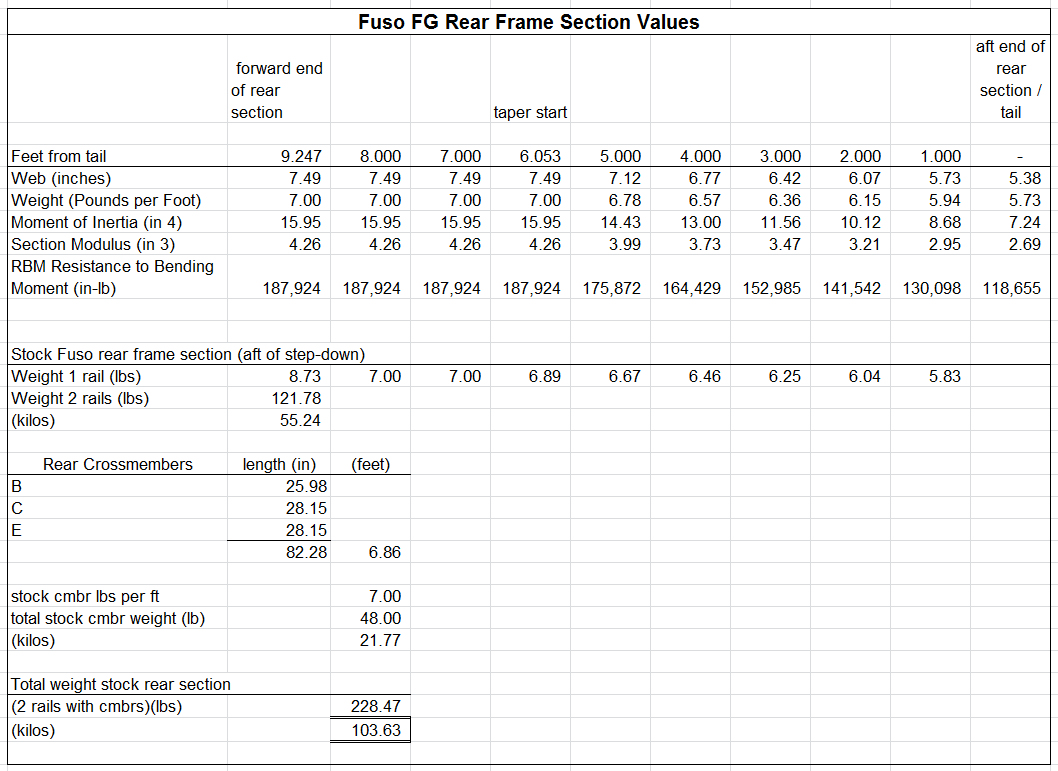

The stock FG frame tapers from a point near the forward rear leaf spring hanger to the tail. The web height diminishes from 7.486" to 5.378".

Highlights:

I thought this info might be of interest.

Notes:

- Web = the vertical portion of the frame

- Flange = the horizontal portion of the frame

- Sleeve = additional reinforcement placed inside the frame

- RBM is used to compare frames of different sizes, shapes and strengths.

Note that the rear section of our frame is extended, so the weight delta is different from a stock frame.

Info on the frame and crossmembers is here: http://www.hackneys.com/mitsu/docs/fusoframemodificationinfo.pdf

Info on the stock frame modulus is here: http://www.hackneys.com/mitsu/docs/fusoframesectionmodulus.pdf

Info on reinforcing the FG step-down section is here: http://www.hackneys.com/mitsu/docs/fusoframeFGreinforcement.pdf

Replacement frame info is from P.G. Adams http://www.pgadams.com/truckframes.php

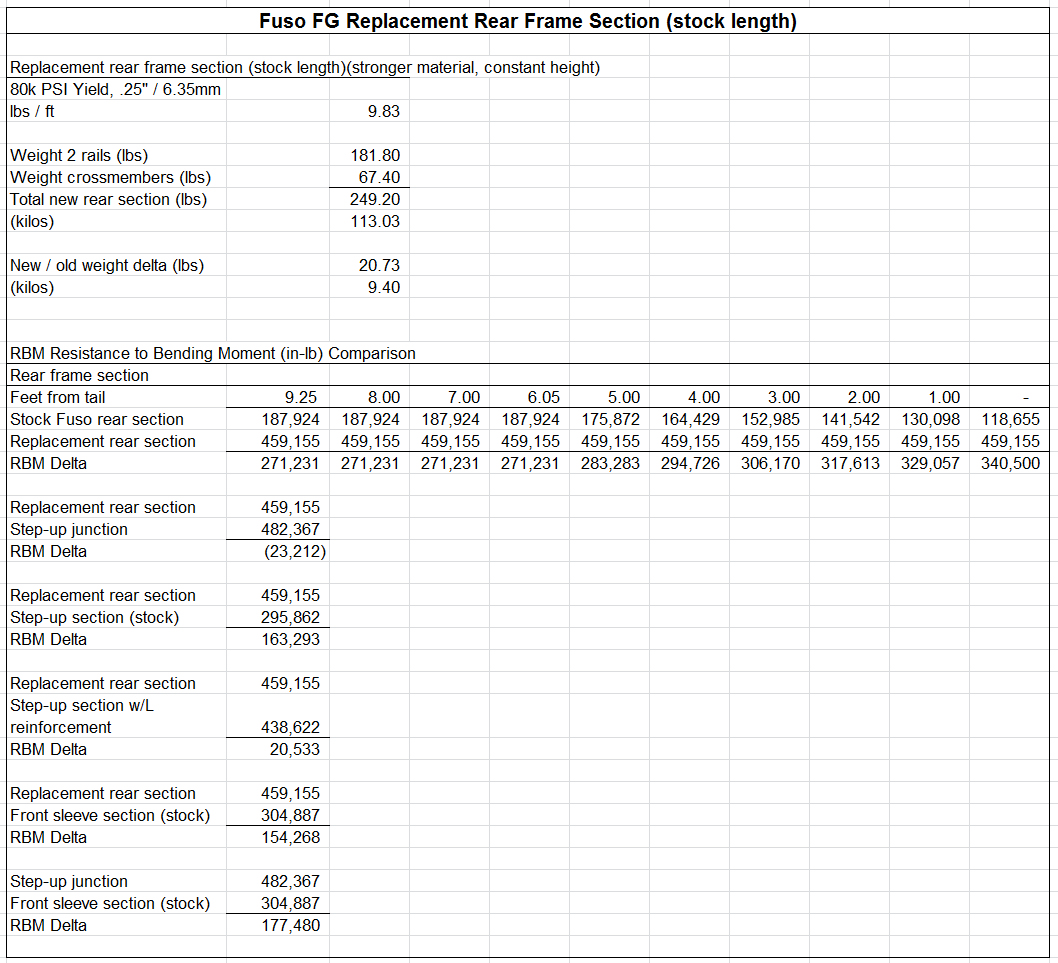

Quoted cost for two 80k PSI rails for our length (longer than stock) is ~$1,600. Cost of drilling holes to match the stock frame varies depending on the number of holes. If you match every hole you can spend as much for the drilling as for the frame rails. (Quote is based on constant height rails with the flanges cut down to match the stock flange width)

The process is to ship them the stock frame section so they can match the holes. They ship the new frame back. Total turnaround is a few weeks including ~two weeks of shipping time. Freight both ways from TX to VT to TX is ~$1,000.

The stock FG frame is C channel.

The stock FG's frame is riveted together at the step-up junctions.

The stock FG frame tapers from a point near the forward rear leaf spring hanger to the tail. The web height diminishes from 7.486" to 5.378".

Highlights:

- The stock rear section is 188k RBM at its strongest point.

- An 80k PSI replacement frame is 459k RBM.

- The step-up junction section is 482k RBM.

- The stock step-up section is 295k RBM (with no reinforcement).

- The front section, which has a stock sleeve, is 305k RBM.

Last edited: