I finally made a decision as to the location for the MaxxFan. I wanted it near the rear of the van since I don't have any windows except the front. I chose to offset it to the driver side so there would be more room on the passenger side roof for a cargo box or just general rack storage. If the vent was centered it either had to go all the way too the front (less air movement in the back) or the roof box would need to be far forward on the roof (harder to get to and limits available space if I get solar panels.) Right now I only have a Yakima cross bars a and Thule roof box, but I plan to build a full roof rack down the road with a passenger side mounted ladder.

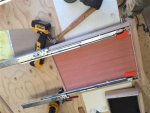

So I carefully marked out the vent location so the edges would hit a high rib of the roof and clear the cross members and drilled four holes at each corner, then I taped around the cutout to prevent scratching the roof:

And cut my lines using a jig saw:

I then painted the cut edges to limit corrosion and ran butyl tap around the opening doubling it up in the low ribs of the roof:

To stiffen the opening and provide a solid backing for the vent screws and the headliner on the bottom I welded a metal frame using 1"x1" tube. The was removed and painted then attached with screws to the roof support and the back roof lip. Then I placed the roof flange in place and drilled all the holes for the mounting screws, and marked the edges for roof sealant.

Black sealant was applied to the roof, the mounting flange was screwed down, and the vent assembly was attached:

I put my Yakima cross bars on and the vent sits about 1/8" higher than the bars. It also only gives me about 1/4" of clearance to the garage door opening if backed in and about 1" when pulled in forward. The approach to the shop is pretty steep:

At this time I just wired it directly to an old week battery I had sitting around for testing, later it will get wired into the house battery system when I get to that point.