Ducky's Dad

Explorer

Thanks.

Lots of subjective words there.they seem to like their bulk charge and float to be on the aggressive side. My belief being Odyssey expects them to be abused and treating them gently might actually be harder on them.

Indeed. Perhaps I should have said "It's my notably small survey opinion that the tolerable range for proper conditioning parameters of EnerSys batteries appears to be smaller and following an uncritical conditioning regime may be negatively impacting their lifespans to an extent beyond their competitive alternatives. YMMV."Lots of subjective words there.

What do you suggest be used instead?And again, voltage is not usually an accurate indicator of anything, least of all a bank's state of health.

Testing current as a function of voltage through a resistance. And there's been offline battery impedance testers for a while. But for using in-situ there's not much practical measurement alternative to using voltage as an analog for status and condition. It's what the IEEE and SAE standards are mostly based upon anyway. I was curious what he meant, perhaps he knew of a online impedance box for automotive use, which would indeed be handy. As it is voltage is a well understood and basically reliable indicator, at least if you believe there are laws in chemistry and physics that must hold true.What do you suggest be used instead?

Odyssey suggests a carbon pile tester, but good ones are not cheap. I have an old school inductive heater battery tester, which is OK for my purposes. The hand held computerized testers are somewhat unreliable. A computerized test bench would be great, but completely impractical for most of us.

And again, voltage is not usually an accurate indicator of anything, least of all a bank's state of health.

Testing current as a function of voltage through a resistance. And there's been offline battery impedance testers for a while. But for using in-situ there's not much practical measurement alternative to using voltage as an analog for status and condition. It's what the IEEE and SAE standards are mostly based upon anyway. I was curious what he meant, perhaps he knew of a online impedance box for automotive use, which would indeed be handy. As it is voltage is a well understood and basically reliable indicator, at least if you believe there are laws in chemistry and physics that must hold true.

Voltage is easy to measure and plenty accurate to judge SOC in our non-critical use.What I want to know is why it even matters when most devices with such a feature (fridge, battery protectors) use voltage as the measurement by which they disconnect when they feel you are nearing an unacceptable level.

No problem as long as it's not done frequently, and under controlled conditions, immediately after hitting 0% start recharging.Yes, 10.5 V is the full discharge

…

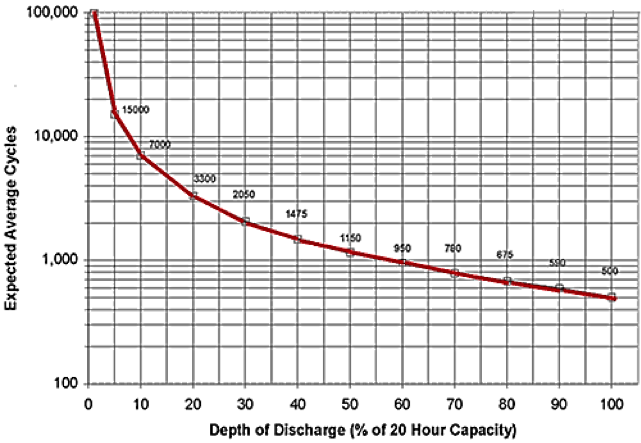

discharging this deep is hard on batteries

Indeed, true. Just note that while a battery is rated for life cycles based on the number of 100% DoD cycles it will do before reaching an end of life capacity that's 80% of its rated or original capacity, doing this will be harsh and requires timely and proper charging to do. Odyssey says their cycle life testing assumes constant voltage at 2.45 V/cell for 16 hours at 1C between 100% DoD of discharges and temperature controlled.No problem as long as it's not done frequently, and under controlled conditions, immediately after hitting 0% start recharging.