So my thoughts on a good camper shell have been changing and evolving.

First I started with a steel and aluminium frame and was eager to cover it with aluminium sheet. But I resigned because of the weight of steel, the lack of flexibility of aluminium and because of the softness and weight of aluminium sheets (aluminium doesn't bounce back so every hit by a branch leaves a dent). Oh I forgot to mention that sticking together alu sheets is not so elegant and prone to create leaks. Plus it would cost me a lot of Sikaflex. In other words a metal cage covered in alu is a dumb idea, although the easiest to make.

Then I thought about epoxy resin and carbon fiber which have a perfect weight and strength, but the cost is terrible so it is not a realistic idea. Even if I ordered carbon fiber mat from China, the amount of epoxy would still create a huge cost.

Finally my thoughts went to fiberglass. My first thought were boats, which have quite thick layer of fiberglass, have good water resistance but are terribly heavy. After some thinking I realized that a boat needs to have a thick layer of fiberglass because it hits the water with great force, so all the surface needs to be equally strong. But this is not the case with a camper shell, which is in touch with air, not water. What's more, the camper shell walls cut through the air instead of hitting water head-on, as is the case wit boats. So my next step was to think of making the camper shell with a few layers of fiberglass: like making the wall only a few millimeters thick and not 2cm. But the shell would be wobbly and prone to cracking, there would be no possibility to hang anything on the walls etc.

So I've been thinking about making some kind of ribs between fiberglass layers, because making a tubular structure gives a lot of strength. I've been looking for some good materials for ribs but couldn't find anything hi-tech.

Well, XPS (extruded polystyrene) is lightweight and good as an insert which would be sandwiched between fiberglass layers. But I am afraid that the resin might melt it and it is still too soft to put a screw in it.

Eventually my thoughts stopped on wood. Making a fiberglass shell with wooden ribs in between layers. The wood would be soaked in resin so it would mean good protection against moisture, it is flexible and doesn't crack, it it relatively lightweight. The downside is that wood seems 'medieval' to me and I am not sure if it is a good building material for such reinforcements/ribs. So this is my first question.

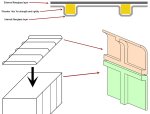

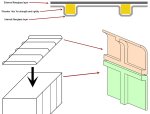

The second questions is how to connect together the pieces of my camper shell. For example the roof with the walls. The diagram below shows my general idea of the ribs which would be covered with fiberglass. On the right I have drawn a hypothetical connection of the roof and a wall.

Should the mating surfaces covered with gelcoat of just fiberglass and resin? I will use sikaflex 221 on the mating surfaces.

Should I use only Sikaflex all along the mating surfaces? Or maybe I should also attach some plates to the vertical surfaces and fit them with screws through fiberglass to the wooden reinforcements. My thought is that Sikaflex will distribute the forces evenly along the whole frame, whereas a few plates with screws would concentrate torsional forces in just a few places. But somehow it seems odd to have my camper walls and roof together by just some sticky goo

Please comment on my ideas. Maybe there are some other building materials or connection methods?

First I started with a steel and aluminium frame and was eager to cover it with aluminium sheet. But I resigned because of the weight of steel, the lack of flexibility of aluminium and because of the softness and weight of aluminium sheets (aluminium doesn't bounce back so every hit by a branch leaves a dent). Oh I forgot to mention that sticking together alu sheets is not so elegant and prone to create leaks. Plus it would cost me a lot of Sikaflex. In other words a metal cage covered in alu is a dumb idea, although the easiest to make.

Then I thought about epoxy resin and carbon fiber which have a perfect weight and strength, but the cost is terrible so it is not a realistic idea. Even if I ordered carbon fiber mat from China, the amount of epoxy would still create a huge cost.

Finally my thoughts went to fiberglass. My first thought were boats, which have quite thick layer of fiberglass, have good water resistance but are terribly heavy. After some thinking I realized that a boat needs to have a thick layer of fiberglass because it hits the water with great force, so all the surface needs to be equally strong. But this is not the case with a camper shell, which is in touch with air, not water. What's more, the camper shell walls cut through the air instead of hitting water head-on, as is the case wit boats. So my next step was to think of making the camper shell with a few layers of fiberglass: like making the wall only a few millimeters thick and not 2cm. But the shell would be wobbly and prone to cracking, there would be no possibility to hang anything on the walls etc.

So I've been thinking about making some kind of ribs between fiberglass layers, because making a tubular structure gives a lot of strength. I've been looking for some good materials for ribs but couldn't find anything hi-tech.

Well, XPS (extruded polystyrene) is lightweight and good as an insert which would be sandwiched between fiberglass layers. But I am afraid that the resin might melt it and it is still too soft to put a screw in it.

Eventually my thoughts stopped on wood. Making a fiberglass shell with wooden ribs in between layers. The wood would be soaked in resin so it would mean good protection against moisture, it is flexible and doesn't crack, it it relatively lightweight. The downside is that wood seems 'medieval' to me and I am not sure if it is a good building material for such reinforcements/ribs. So this is my first question.

The second questions is how to connect together the pieces of my camper shell. For example the roof with the walls. The diagram below shows my general idea of the ribs which would be covered with fiberglass. On the right I have drawn a hypothetical connection of the roof and a wall.

Should the mating surfaces covered with gelcoat of just fiberglass and resin? I will use sikaflex 221 on the mating surfaces.

Should I use only Sikaflex all along the mating surfaces? Or maybe I should also attach some plates to the vertical surfaces and fit them with screws through fiberglass to the wooden reinforcements. My thought is that Sikaflex will distribute the forces evenly along the whole frame, whereas a few plates with screws would concentrate torsional forces in just a few places. But somehow it seems odd to have my camper walls and roof together by just some sticky goo

Please comment on my ideas. Maybe there are some other building materials or connection methods?