WeekendWannabe

New member

I have a family member with a 2012 (5th Generation) 4Runner Trail with a Shrockworks bumper. Shrockworks folded suddenly, leaving a lot of people without their orders and without availability for parts. A design flaw in the bumper for these vehicles is the turn signal housings; they are supplied by Hella (part # 00822107) and are prone to burning or melting due to the 4Runner's use of them as a daytime running light. Finding replacements for these housings has gotten difficult to impossible; there are still some websites that list these housings for sale, but I have yet to find one who will make good on an order. Every order I've placed for new housings has been ignored or cancelled. My original plan was to put LED lights in the Hella housing and add the correct resistor, but the lack of replacement parts has forced me to get creative with a solution.

I didn't do a great job of taking photos, but I will do my best to explain what to do. This is not a difficult job and anyone with any experience of wiring will be able to do it.

The light we are addressing is in the outer-most hole:

Hella 8821 turn signal 0082207

The other problem is the hole cut by Shrockworks for this housing is not a standard size for flush or recessed mount trailer lights - many of which are only 2-wire designs and won't work as a combination DRL and turn signal without a lot of messing with relays and wiring. The hole is 2.44" diameter, which is just small enough that 2.5" lights don't fit. I spent a not-insignificant amount of time trying to problem-solve this, everything from removing the bumper and welding a plate into the hole so a new one could be drilled, to die-grinding the hole larger, to finding someone to 3D print an insert (maybe I've been watching too much Superfast Matt, because I did briefly look up 3D scanners).

Links break, so I will be including all relevant information I can, including part numbers and photos of the parts so others can replicate this retrofit. I'm not affiliated with any of these products and get no kickbacks from the links provided.

Parts:

2.5" blank rubber grommets. I went with these because they were cheap and I could get them quickly, but any blank 2.5" grommet will do.

Model# K63N53

3-wire waterproof connectors of your choice: I picked the NAOEVO 3 Pin Connector with 16 ga wire, but any waterproof 3-wire automotive connector will work. You don't have to use a plug for this, but it makes the assembly easier and it's a favor to anyone in the future who might need to remove the bumper or maintain/repair the electrical. You can, of course, hard-wire all this directly to the vehicle if you choose.

ASIN# B092ZCM9VK (this only works on Amazon as far as I know)

Waterproof butt connectors: I happen to have these Haistronica solder seal wire connectors in my toolbox, so that's what I've been using.

Model: HX1004

UPC: 192687297658

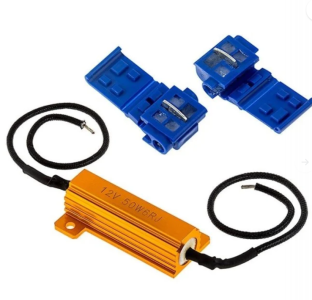

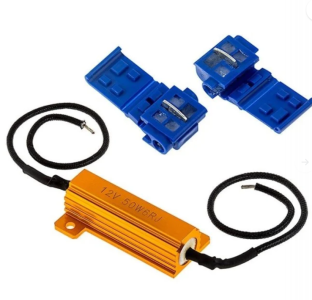

Resistors: 6Ohm, 50W -

Part#: RL-650K-2PK (any 6 Ohm resistor will work) - throw away those lousy cable taps it comes with, we won't be using them. I sourced mine from SuperBrightLEDs.com, but they are common all over the internet.

GloLight Uni-Lite LED Clearance or Side Marker Light With Grommet - Turn - Round - Amber Lens

Part# MCL121AK9PVG or any 3/4" amber light with 3 wires. I found these at eTrailer.com

Tools:

Other supplies:

Step 1: Remove the old light from the bumper.

The installer for the lights on this particular vehicle hard-wired them into the OE harness without a plug, so I cut the wires as close to the Hella light side as possible. The signal housing is held in by three screws from the back of the bumper with some nuts that are very difficult (impossible) to reach. The hardware used by Shrockworks is cheap and prone to rust. I removed the plastic lights by placing a mallet against the clear lens and smacking it with a hammer. This broke the three plastic tabs off and the light housing completed it's sudden Plinko Journey off various suspension parts before rolling to freedom down the driveway. This is fine, we are not using those screw holes.

You may now put the hammer back in the drawer

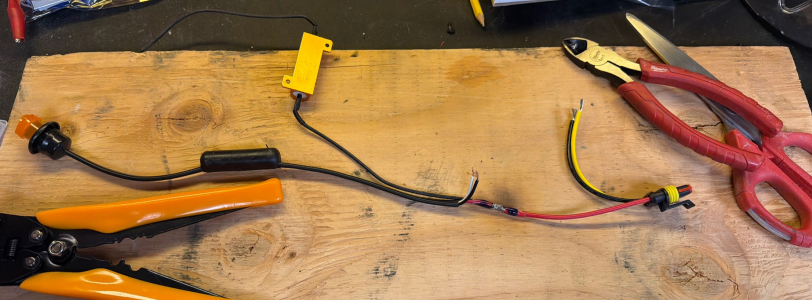

Step 2: Mock up your wiring.

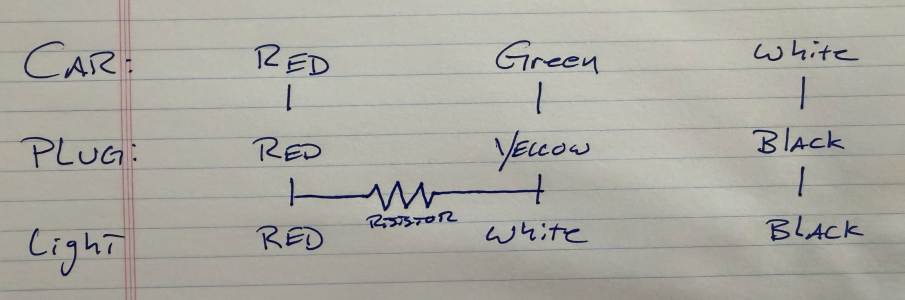

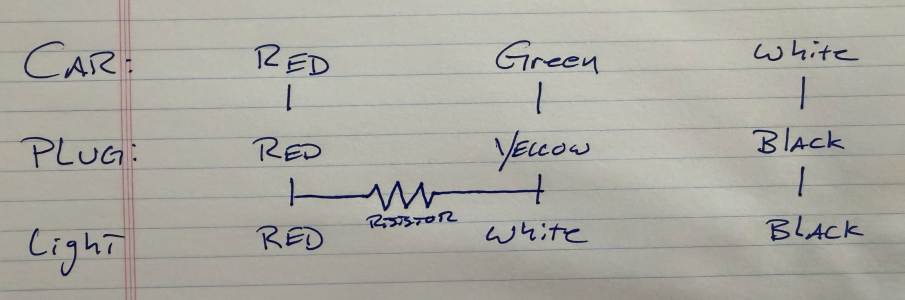

I used my alligator test leads for this, but it's optional. Here is the diagram I drew up showing the color of the wiring I found on this vehicle, the color wiring on the plugs I had, and the wiring on the new lights. YOUR WIRING MAY BE DIFFERENT! Someone was in this vehicle before me so I don't know if these are the factor wire colors. The plugs you buy might not be the same color wires as the ones I bought - the important thing is to make sure you don't cross things up when wiring the plugs. I strongly recommend mocking up your wiring and using a test-light to make sure you know what OE wire does.

When you are sure the wiring is correct and you've tested the DRL, signals, 4-way hazards, and all those functions with the headlights on and off, you can now start wiring.

Install the female side of your plug on the end of the OE wiring: In this case, plug's red wire went to the car's red, the plug's yellow went to the car's green, and the plug's black went to the car's white (see above). Use the waterproof connectors and the heat gun to make sure you get a good seal; you will need to hold the connection very still while it cools!

Start by cutting the connectors off the end of the light so you can wire on your own waterproof plug.

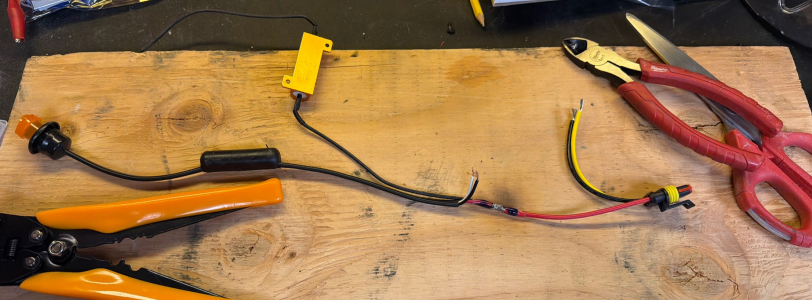

Now you can begin assembling the new light, resistor, and plug. Fortunately you can do this at the bench. This is a little more tricky, because you will need to wire the resistor between the red and white/yellow wires to prevent hyper-flashing. The resistor has a smaller gauge wire, so I paired it with the smaller wire on the light and put the thicker plug wire out the other side. I'm not saying this is the best way to do this, I just didn't want to mess with pinning plugs. Remember that the resistor will get hot - so leave enough of a loop on the resistor wire so you can tie it away from the other wires once you get it in the vehicle.

Slide the wires into each end of the connector and use the heat gun on it, moving around so nothing burns. You will see the connector shrink around the wires, the colored glue band will melt, and the solder should start to flow. I like to get the glue on each end melted first and then work towards the middle so the solder is well supported. Be careful no to melt or scorch the wire insulation. I do not recommend using a lighter for this step, a heat gun has more control and is less likely to burn.

Repeat this with the other side of the resistor and connect it to the red wires. Finally connect the black wires together.

Make two of these assemblies, plug them in and test that everything works properly.

Step 3: Mounting

If you are using the parts list provided, you will need to cut a 3/4 hole in the middle of your grommet blanks with a sharp knife. Fit this over the LED light and then into the hole in the bumper. This will be a tight fit and it will be slightly concave. You can, if you want, remove a wedge of grommet material, but I didn't find it necessary. Work the groove on the grommet until it's seated in the hole, it may not sit flat, which is fine as long as it's centered and the dish shape is even all around.

Connect the plug and tidy up the wiring with your wrap, split-loom, or product of choice. Make sure the resistor is not resting on anything that could melt, it will get hot during use. I zip tied the resistors to the back of the now useless mounting box to help cool the resistor and keep it from touching the wiring.

I didn't do a great job of taking photos, but I will do my best to explain what to do. This is not a difficult job and anyone with any experience of wiring will be able to do it.

The light we are addressing is in the outer-most hole:

Hella 8821 turn signal 0082207

The other problem is the hole cut by Shrockworks for this housing is not a standard size for flush or recessed mount trailer lights - many of which are only 2-wire designs and won't work as a combination DRL and turn signal without a lot of messing with relays and wiring. The hole is 2.44" diameter, which is just small enough that 2.5" lights don't fit. I spent a not-insignificant amount of time trying to problem-solve this, everything from removing the bumper and welding a plate into the hole so a new one could be drilled, to die-grinding the hole larger, to finding someone to 3D print an insert (maybe I've been watching too much Superfast Matt, because I did briefly look up 3D scanners).

Links break, so I will be including all relevant information I can, including part numbers and photos of the parts so others can replicate this retrofit. I'm not affiliated with any of these products and get no kickbacks from the links provided.

Parts:

2.5" blank rubber grommets. I went with these because they were cheap and I could get them quickly, but any blank 2.5" grommet will do.

Model# K63N53

3-wire waterproof connectors of your choice: I picked the NAOEVO 3 Pin Connector with 16 ga wire, but any waterproof 3-wire automotive connector will work. You don't have to use a plug for this, but it makes the assembly easier and it's a favor to anyone in the future who might need to remove the bumper or maintain/repair the electrical. You can, of course, hard-wire all this directly to the vehicle if you choose.

ASIN# B092ZCM9VK (this only works on Amazon as far as I know)

Waterproof butt connectors: I happen to have these Haistronica solder seal wire connectors in my toolbox, so that's what I've been using.

Model: HX1004

UPC: 192687297658

Resistors: 6Ohm, 50W -

Part#: RL-650K-2PK (any 6 Ohm resistor will work) - throw away those lousy cable taps it comes with, we won't be using them. I sourced mine from SuperBrightLEDs.com, but they are common all over the internet.

GloLight Uni-Lite LED Clearance or Side Marker Light With Grommet - Turn - Round - Amber Lens

Part# MCL121AK9PVG or any 3/4" amber light with 3 wires. I found these at eTrailer.com

Tools:

- Wire cutter

- Wire stripper

- Heat gun

- Sharp hobby knife or small utility knife

- Hammer

Other supplies:

- Cable Ties

- Cord wrap of your choice - I used cloth tape.

- Aligator test leads

Step 1: Remove the old light from the bumper.

The installer for the lights on this particular vehicle hard-wired them into the OE harness without a plug, so I cut the wires as close to the Hella light side as possible. The signal housing is held in by three screws from the back of the bumper with some nuts that are very difficult (impossible) to reach. The hardware used by Shrockworks is cheap and prone to rust. I removed the plastic lights by placing a mallet against the clear lens and smacking it with a hammer. This broke the three plastic tabs off and the light housing completed it's sudden Plinko Journey off various suspension parts before rolling to freedom down the driveway. This is fine, we are not using those screw holes.

You may now put the hammer back in the drawer

Step 2: Mock up your wiring.

I used my alligator test leads for this, but it's optional. Here is the diagram I drew up showing the color of the wiring I found on this vehicle, the color wiring on the plugs I had, and the wiring on the new lights. YOUR WIRING MAY BE DIFFERENT! Someone was in this vehicle before me so I don't know if these are the factor wire colors. The plugs you buy might not be the same color wires as the ones I bought - the important thing is to make sure you don't cross things up when wiring the plugs. I strongly recommend mocking up your wiring and using a test-light to make sure you know what OE wire does.

When you are sure the wiring is correct and you've tested the DRL, signals, 4-way hazards, and all those functions with the headlights on and off, you can now start wiring.

Install the female side of your plug on the end of the OE wiring: In this case, plug's red wire went to the car's red, the plug's yellow went to the car's green, and the plug's black went to the car's white (see above). Use the waterproof connectors and the heat gun to make sure you get a good seal; you will need to hold the connection very still while it cools!

Start by cutting the connectors off the end of the light so you can wire on your own waterproof plug.

Now you can begin assembling the new light, resistor, and plug. Fortunately you can do this at the bench. This is a little more tricky, because you will need to wire the resistor between the red and white/yellow wires to prevent hyper-flashing. The resistor has a smaller gauge wire, so I paired it with the smaller wire on the light and put the thicker plug wire out the other side. I'm not saying this is the best way to do this, I just didn't want to mess with pinning plugs. Remember that the resistor will get hot - so leave enough of a loop on the resistor wire so you can tie it away from the other wires once you get it in the vehicle.

Slide the wires into each end of the connector and use the heat gun on it, moving around so nothing burns. You will see the connector shrink around the wires, the colored glue band will melt, and the solder should start to flow. I like to get the glue on each end melted first and then work towards the middle so the solder is well supported. Be careful no to melt or scorch the wire insulation. I do not recommend using a lighter for this step, a heat gun has more control and is less likely to burn.

Repeat this with the other side of the resistor and connect it to the red wires. Finally connect the black wires together.

Make two of these assemblies, plug them in and test that everything works properly.

Step 3: Mounting

If you are using the parts list provided, you will need to cut a 3/4 hole in the middle of your grommet blanks with a sharp knife. Fit this over the LED light and then into the hole in the bumper. This will be a tight fit and it will be slightly concave. You can, if you want, remove a wedge of grommet material, but I didn't find it necessary. Work the groove on the grommet until it's seated in the hole, it may not sit flat, which is fine as long as it's centered and the dish shape is even all around.

Connect the plug and tidy up the wiring with your wrap, split-loom, or product of choice. Make sure the resistor is not resting on anything that could melt, it will get hot during use. I zip tied the resistors to the back of the now useless mounting box to help cool the resistor and keep it from touching the wiring.