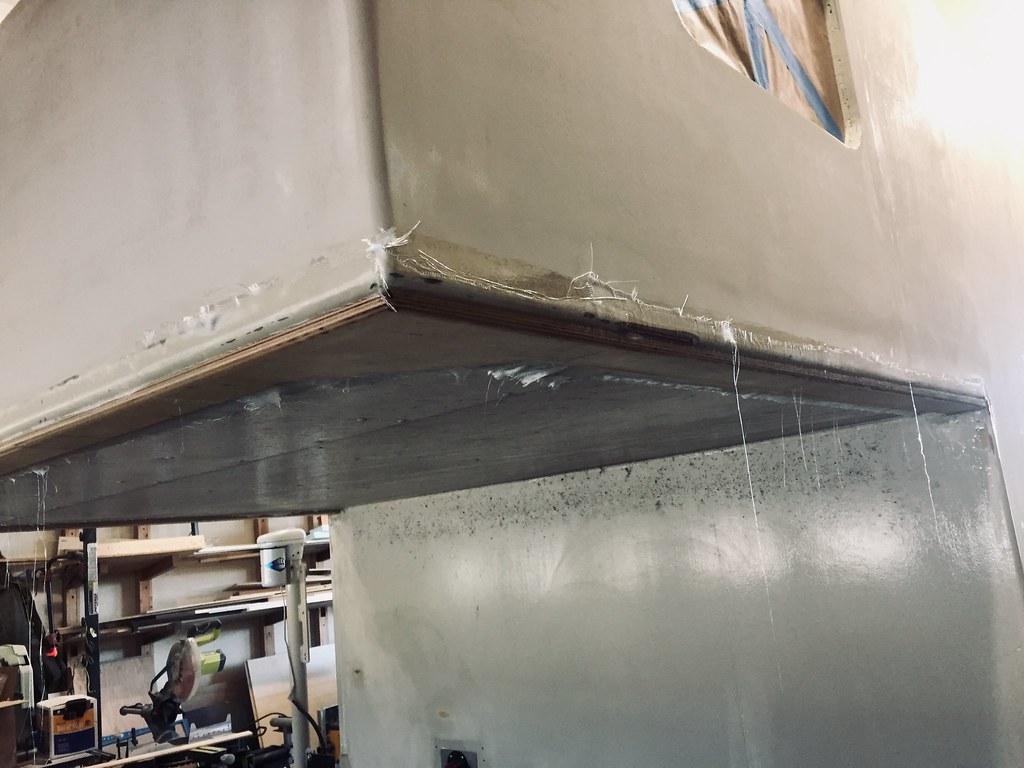

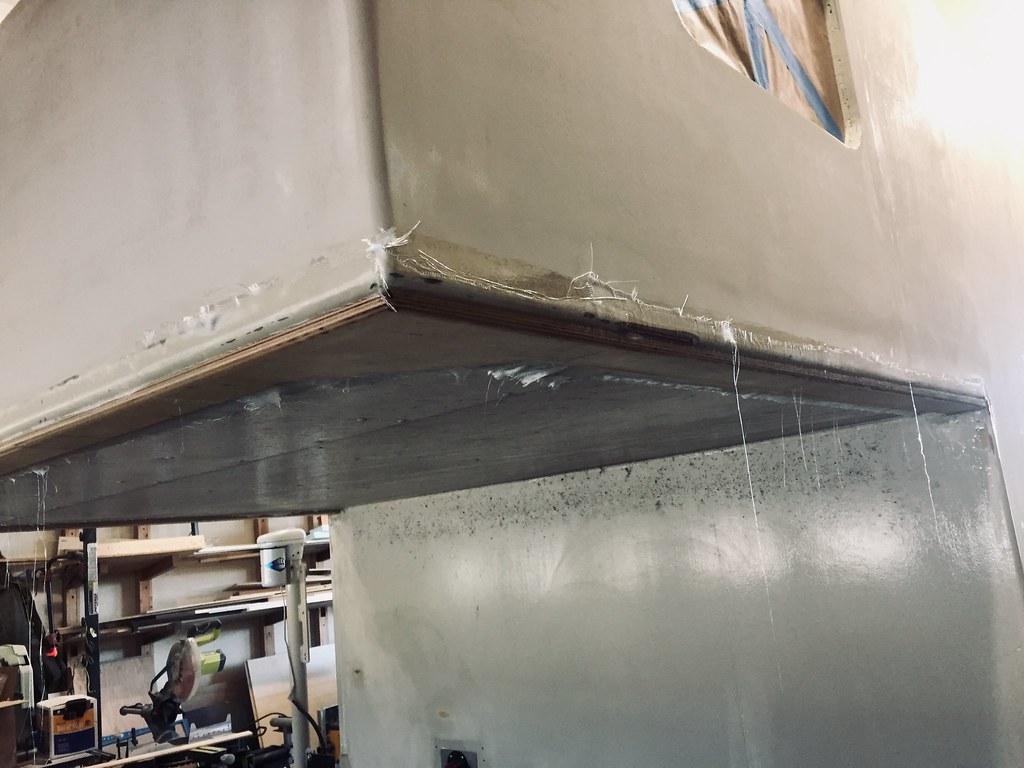

Was it a bit of a pain in the glass, or a major pain in the glass?... BTW, laying glass on gravity challenged surfaces is entertaining.....

...

Joking aside, any tips or suggestions?

Was it a bit of a pain in the glass, or a major pain in the glass?... BTW, laying glass on gravity challenged surfaces is entertaining.....

...

Thank you.Best method I've found, and what I used, was to go this route...

Apply base/seal coat of epoxy, let cure.

Sand / de-gloss base coat, then apply a coat of epoxy.... then wait....

Wait time will depend upon epoxy you use and temperature.

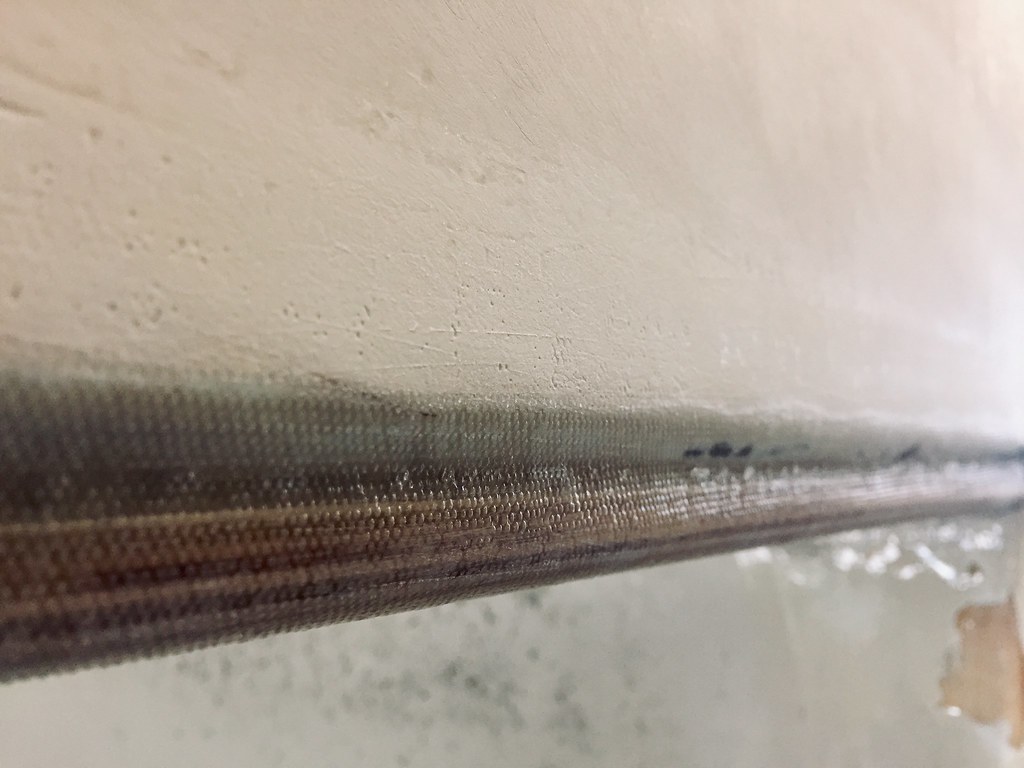

But you want it to be tacky enough to grab and hold the glass, allowing you to conform the glass to the surface.

Once fitted, wet out the glass with another coat of epoxy.

Finally, before the wet out coat is 100% dry, apply another coat of epoxy.

This application should iron out any wrinkles and air pockets you might have in the glass.

Once that is cured, you do your sanding, and 1-2 more coats of epoxy to completely fill the glass weave and blend the transitions.

Lighter than I would have guessed, having never used it. Thanks.Good question, but I don't have a good answer for you. But I'm not concerned in the least.

After the solvents evaporate out of it when applied and cured, maybe 35# ??