Imnosaint

Gone Microcamping

The Franklin Rack

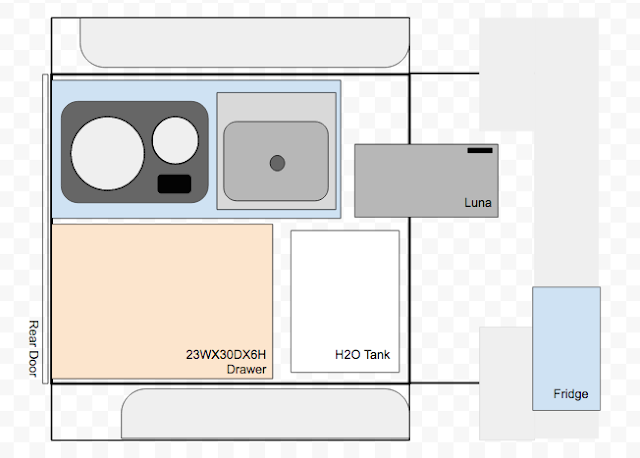

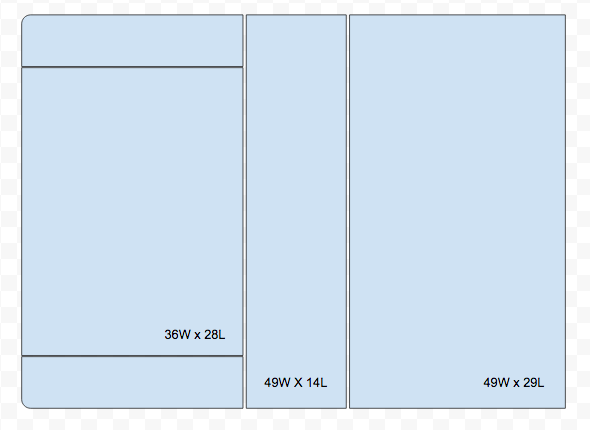

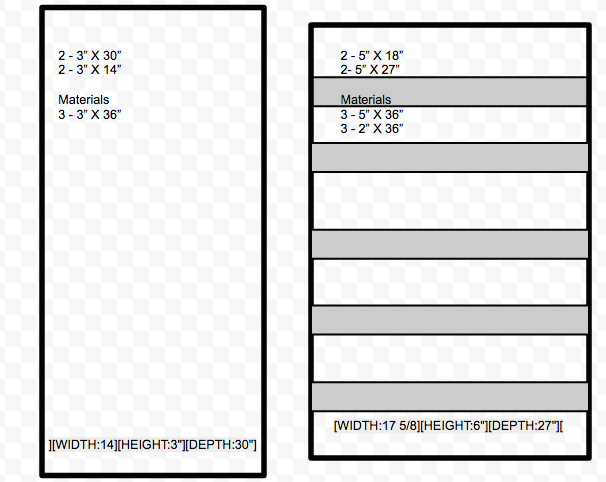

This build will have more to do on the interior than the exterior and I'm trying to apply lessons learned from previous builds, one of which for our purposes, is that we don't need a huge roof rack, nor do I want to block the sunroof, ill-placed as it is. This being the case, I went economy on top to put more money to the interior (drawer, stove and fridge system) and picked up a Rage Powersports low profile cargo basket for $104.99 on Amazon - the reason I'm calling it the Franklin Rack. That being said, it is an easier alternative to the GEN 3's wood roof rack.

All assembled there's not much more structural integrity than an erector set, getting less than what I paid for perhaps. Its intended use, like on the H3, is to have a place for recovery gear; shovel, TREDs, HiLift and a three-gallon Rotopax can. It's 39.5x36 inches, allowing a little under ten square feet of space. The Garvin Sport Rack on the H3 allowed 14.4 square feet - thirty percent less room - plus this little basket won't hold an awning. But I have other plans for that.

To make the best use of this real estate, and to reinforce the rack a bit more, I added 2" aluminum flat bar, a 20" piece to provide mounting area for the shovel, and two 10" pieces to do the same for the Rotopax.

I did a test fit with the a TRED in place - it will be mounted with a cable lock like on the Garvin rack.

And then drilled holes and mounted the slats with 3/16" aluminum rivets.

My cuts leave much to be desired, but considering what I'm working with - a B&D jig saw with a metal cutting blade - I'll live with it. I won't be standing on top of the Monty eyeballing my shoddy craftsmanship.

With the slats attached I shot the whole rack with Duplicolor's bed liner.

Once the paint set I added the hardware,

...and mounted the rack on the Montero. I'm giving it 24 hours before I mount the gear. It kind of has a factory feel to it with the cut-outs on the basket mimicking those on the stanchions of the factory rack, if you squint a your eyes a bit.

This build will have more to do on the interior than the exterior and I'm trying to apply lessons learned from previous builds, one of which for our purposes, is that we don't need a huge roof rack, nor do I want to block the sunroof, ill-placed as it is. This being the case, I went economy on top to put more money to the interior (drawer, stove and fridge system) and picked up a Rage Powersports low profile cargo basket for $104.99 on Amazon - the reason I'm calling it the Franklin Rack. That being said, it is an easier alternative to the GEN 3's wood roof rack.

All assembled there's not much more structural integrity than an erector set, getting less than what I paid for perhaps. Its intended use, like on the H3, is to have a place for recovery gear; shovel, TREDs, HiLift and a three-gallon Rotopax can. It's 39.5x36 inches, allowing a little under ten square feet of space. The Garvin Sport Rack on the H3 allowed 14.4 square feet - thirty percent less room - plus this little basket won't hold an awning. But I have other plans for that.

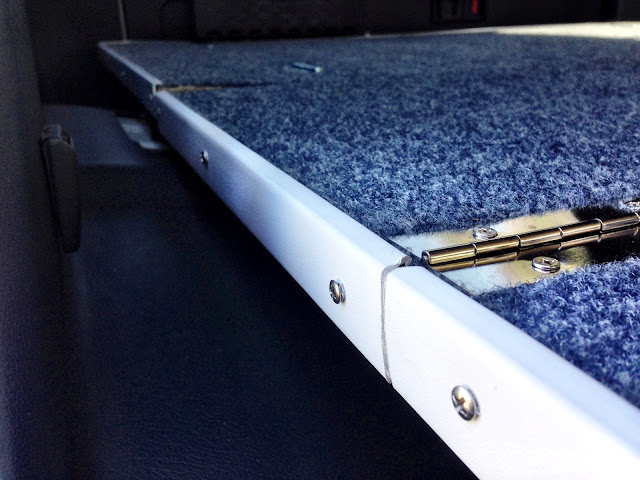

To make the best use of this real estate, and to reinforce the rack a bit more, I added 2" aluminum flat bar, a 20" piece to provide mounting area for the shovel, and two 10" pieces to do the same for the Rotopax.

I did a test fit with the a TRED in place - it will be mounted with a cable lock like on the Garvin rack.

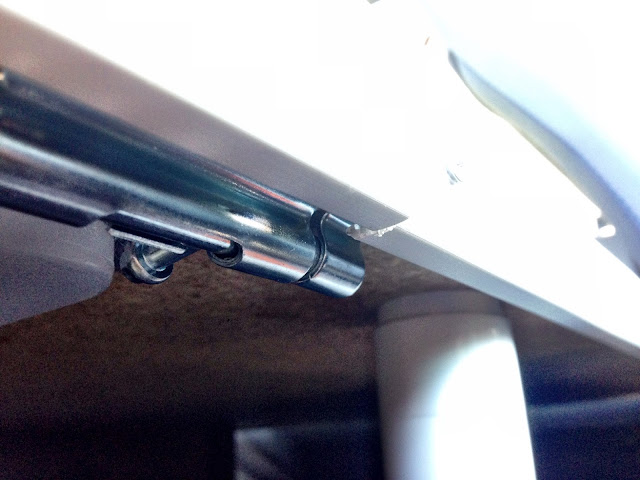

And then drilled holes and mounted the slats with 3/16" aluminum rivets.

My cuts leave much to be desired, but considering what I'm working with - a B&D jig saw with a metal cutting blade - I'll live with it. I won't be standing on top of the Monty eyeballing my shoddy craftsmanship.

With the slats attached I shot the whole rack with Duplicolor's bed liner.

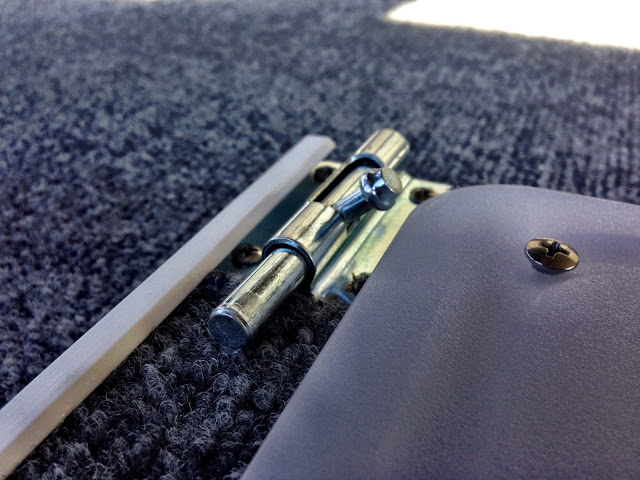

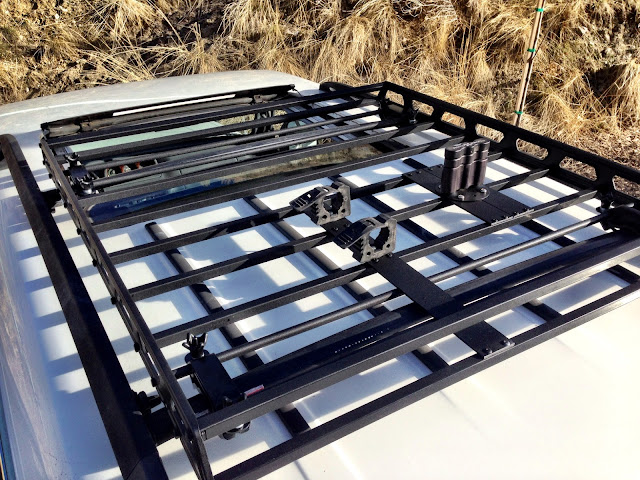

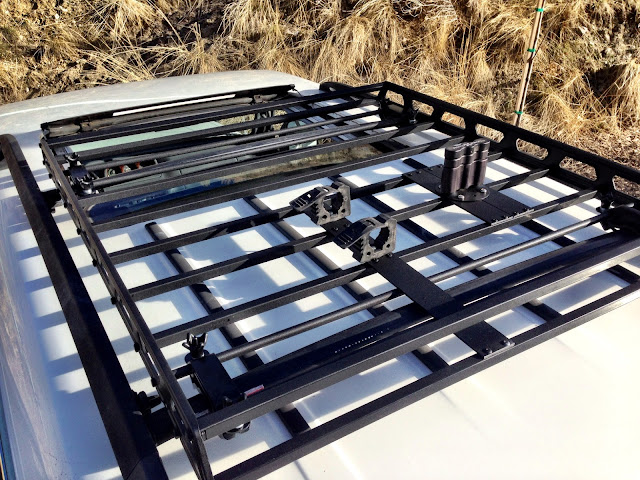

Once the paint set I added the hardware,

...and mounted the rack on the Montero. I'm giving it 24 hours before I mount the gear. It kind of has a factory feel to it with the cut-outs on the basket mimicking those on the stanchions of the factory rack, if you squint a your eyes a bit.

Last edited: