Hey, yes, you are right, the backdoor has been a recent project. We started with planning a few weeks ago and have been slowly working our way through the various items.

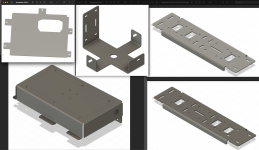

From the "bracket screenshot" above, the right two are for mounting Rotopax or similar items to the outside of the rear door. The upper left will take a Redvision display (and possibly other stuff later on), the lower left is the enclosure for the outside parts of the diesel heater, and the top row middle is for holding our trash can (a bear safe container, secured with a RokStrap).

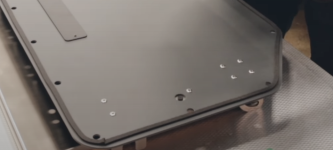

Here's the door, when we attached the RhinoRack loadbars:

View attachment 832082

The blue masking tape was just for mounting. The left side of the door will get two 2G Rotopax, and between Rotopax and shovel, there will be a small Pelican case where we'll put dirty diesel stuff (gloves, spout, etc.).

Regarding the shower enclosure, we do have the Alu-Cab shower cube, it's mounted on the driver's side.

This has been one of the declared goals of our build: there is a place for everything and we generally don't want to move something to get to something else. Goal was 2 minute set up and break down times, including bed and awning. It's doable with our setup, since most things are stored in a way that they pack away easily after use.

This is incredibly true! I was looking at the Goose Gear build-out for the Gladiator and while it would have saved us a lot of time, it just wouldn't have done what we wanted it to do. Weight wise, our setup is actually slightly lighter than a full Goose Gear setup, but about a billion times more comfortable in use. It wasn't all that much cheaper though, maybe a bit under half the price or so. Building with 80/20 gets out of hand VERY quickly.

We have saved money on the build, but on the other hand, we would have been done last year if we had purchased the parts. We probably could make do with these as well, it just wouldn't have been as nice, and we are an age where nice and comfortable is important. But you also end up doing a lot of stuff once, and once only, even though they are at a quality level that could be sold with good consciousness to other people.

Like the mosquito net my wife made (me holding it on during a "does it fit" test):

View attachment 832083

It does not have the canvas like the Alu-Cab net, but it's the same ultrafine netting, high quality zippers, etc.

Then my wife made cushions, including anti-slip bottom:

View attachment 832084

View attachment 832085

And here's a demonstration of the table in the high cabinet while we were still working on it:

Oh, and yes, we do bring the kitchen sink, really:

View attachment 832086

But I have to agree, the DIY part has enabled us to build the truck exactly the way we envisioned it, not some put together interpretation of a shop not understanding our ideas and just using what they know and have always used or done.