No problem on posting pictures. I love sharing these things on the forums. I almost feel guilty sometimes when I find the solution to a problem from the busted knuckles and headaches other people have had to do to come up with some of these solutions. After I got my wifes trooper the Torque on Demand system on the borg warner transfer case wasn't working. I was able to browse around and find how to get the troubleshoot codes. Then another forum deciphered the codes to tell me the two speed sensors on the transfer case were not working properly. I was trying to figure out why several people were quoted up to $1500 for the dealer to replace them. After about 5 minutes of crawling underneath I saw that the wiring harness with the sensors is a pain to remove and can't be done easily with the transfer case in. My solution was just soldering the wires for the sensors I had removed from the parts car. It isn't as good as a fix for what the total replacement would be but its an old car with 150k miles on the body I'm sure my soldering will outlast that vehicle.

For the hi lift jack mount I put a half inch round stock dowel in there on the top for a lock and a backup if the threaded knobs happened to vibrate out. I don't think it would happen but you never know! It was just kind of hidden from the pictures.

I think I have most of what I want in the gas can holder figured out. I have some aluminum left over from the slide out drawers I made for my friends 4runner that I will use for the material. When I installed the el cheapo can holder off of amazon I didn't really like the way it worked out and left a lot of ugliness behind. My thoughts on version 2.0 is to have the aluminum sheeting cover the entire licence plate area of the small back door. (use a little bit of foam gasket around the edges of the aluminum to help keep the rear door sealed and clean) When you remove the licence plate plastics and light there are several other little plastic crew connectors and holes that become exposed. The bulk of the weight of the assembly will be secured with the licence plate mounting holes. They were a decently secure mounting point but in my opinion not up to the heavy duty standards alone. There are two bolts on the side of the small door that I can utilize to bolt a piece of aluminum too and then attach that to the gas can holder. I think it would also be prudent to take apart the back door's plastic and utilize the other holes for thru bolts with backing washers for reinforcement. The hinges on the door are pretty stout but I see vibrations causing long term problems if it isn't fully secured.

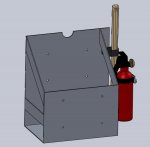

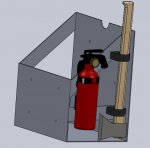

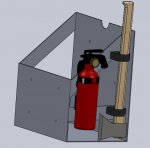

The width of the rear door is a bit more than a gas can. There was about 1.625" of what I call free space to utilize. So I thought it would be a decent place to mount an axe or something there and also a fire extinguisher. I'm not sure quite yet if I want the axe and fire extinguisher on the outside or mounted inward closer to the door latch handle. It won't affect the design much but would just need reversing.

For the licence plate light I could reuse the one thats on the trooper but for this I'll probably just put one of the nice little LED ones on there.

https://www.etrailer.com/Trailer-Lights/Optronics/LPL55CB.html I have one on my M1010 and it has held up great for 4 years.

For the axe mount and most likely the fire extinguisher I will end up using these cool rubber mounting straps I found on Amazon.

http://www.amazon.com/Original-Quic..._UL160_SR104,160_&refRID=16TH4NVB1EV5XF77WW0V

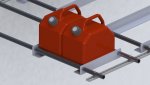

As far as the roof racks and crossbars go I'm trying to figure out the exact goals. The easiest solution for doing simple crossbars is to buy a set of the surco TR100 mounting brackets (~$70) and bolt some aluminum bars across them. They do raise the level of the roof rack fairly high. I'm not 100% sure if that helps on mileage or if it just worked out that way. I have two 6' pieces of aluminum L track that I don't think I will use on my M1010 project. They would be just long enough to go from the rear mounting bolts all the way to the front bolts. Using aluminum L track I would have to machine some aluminum mounting brackets to tie into the troopers roof bolts. The things I will most likely put on the roof would be a cooler and maybe a couple action packers with extra gear. As far as those go I think I could make a specific set of cross bars with the L track mounting bolts that could removed easily for the cooler and another set for a couple action packers. Then when not in use they just pop off.

http://www.uscargocontrol.com/Ratch...Accessories/Double-Stud-Fitting-w-Bolt-Thread

With my limited roof rack experience the biggest complaint I had was having to always check to make sure that everything was secure and not having a specific tie area. I think that by putting L track the whole length of the roof it would provide you with a crazy variety of options. Fuel and water can holders, cooler mount, action packer mount, and you could even just attach a factory roof rack basket with a set of bars too. With the cost of heavy duty aluminum vs the cost of expensive name brand rack parts you can pretty much make dozens of attachments and still be money ahead.