PacificNorthWestJeeper

Blissfully Lost

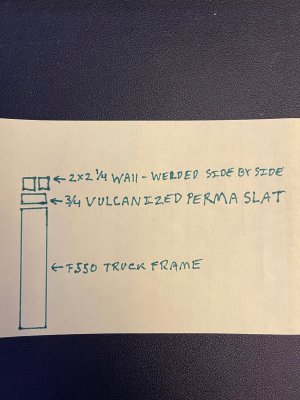

I am moving on to the 'rail on rail' subframe part of my build on my 2017 F550.

The 2x5 or 3x5 ¼ wall tubing seems to be the standard for the rail on rail for commercial vehicles.

I am trying to save every vertical inch I can.

Has anyone seen/done a 2x2 ¼ wall subframe, but then weld the 2x2 side by side so therefore it makes in 4 inches wide by 2 inches tall?

I would cross-brace and gusset joints...

My thought is now you have 4 vertical walls that are a ¼ thick which, in theory, should easily handle the vertical torsion load????

If not other thoughts on low profile rail-on-rail setups? 2x3 welded side by side, or??????

Thoughts?

.

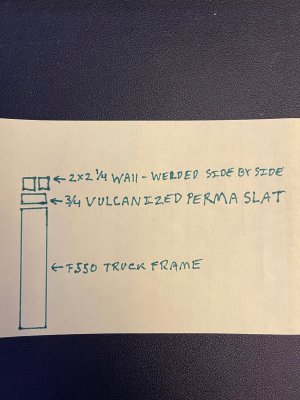

The 2x5 or 3x5 ¼ wall tubing seems to be the standard for the rail on rail for commercial vehicles.

I am trying to save every vertical inch I can.

Has anyone seen/done a 2x2 ¼ wall subframe, but then weld the 2x2 side by side so therefore it makes in 4 inches wide by 2 inches tall?

I would cross-brace and gusset joints...

My thought is now you have 4 vertical walls that are a ¼ thick which, in theory, should easily handle the vertical torsion load????

If not other thoughts on low profile rail-on-rail setups? 2x3 welded side by side, or??????

Thoughts?

.

Last edited: