You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

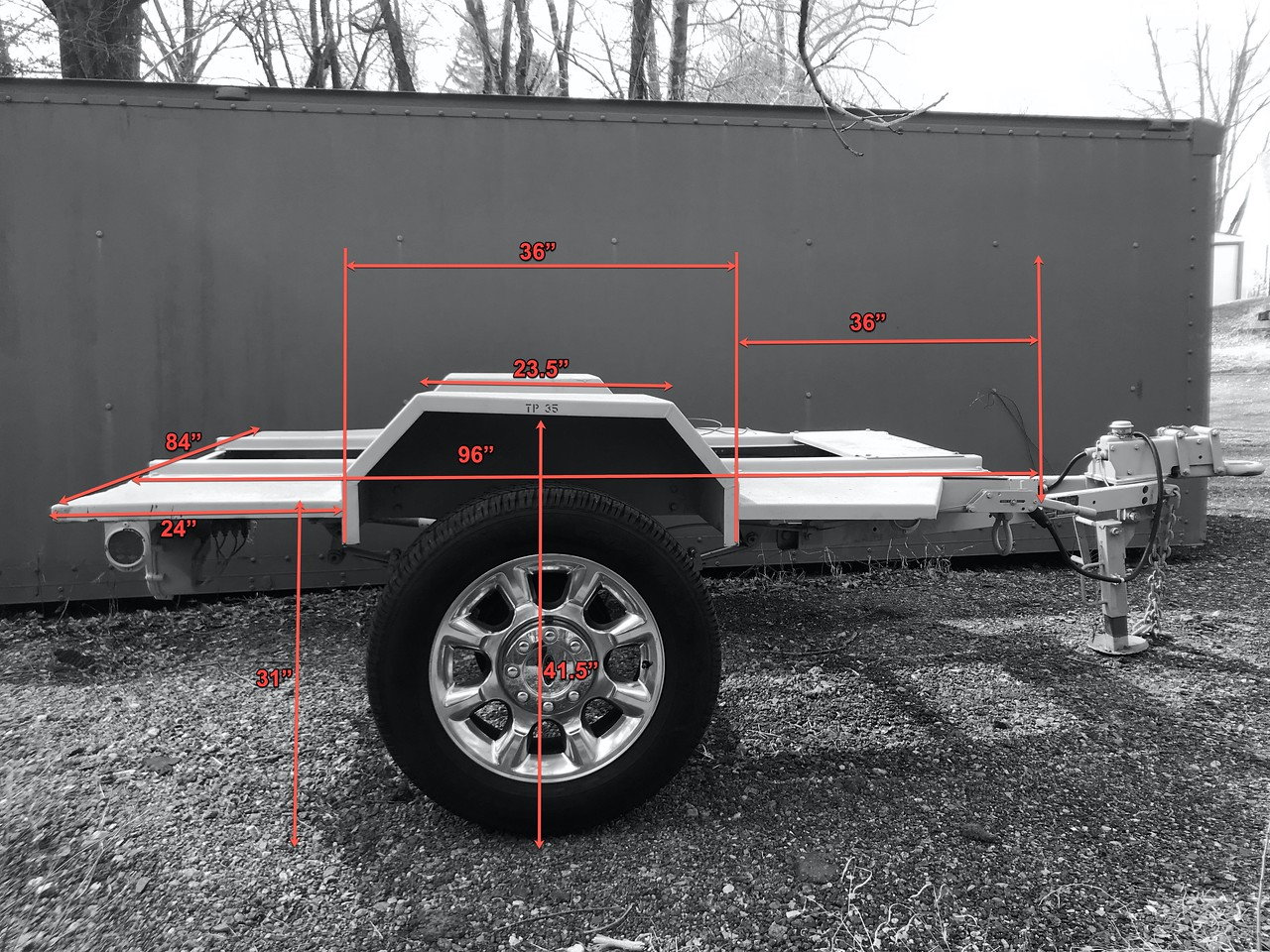

M116A3 - First Trailer for Overland Travels!

- Thread starter unleashd

- Start date

old_CWO

Well-known member

Fwiw.

I found surgebrakes a maintenance hassle, prone to hunting under many conditions. Plus backing uphill may need you locking them out at the actuator. (I modified my brakes to release pressure when shifted to reverse which fixed that.)

Further. Driving off road on slippery/loose surface it can be handy to manually actuate trailerbrakes independantly of the car.

Btw,

Save money and work, Keep the lunette. Tall tails of them being noisy or whatever come from Chickenlittles who simply repeat internet blabber or lack loading and simple mechanical task skills

Not generally a fan of surge brakes myself except perhaps on boat trailers where they get dunked all the time. Your point about being able to manually actuate the electric brake is spot on; that capability has saved my bacon a couple of times over the years.

The lunette is part of the surge brake actuator on these trailers. The whole deal unbolts and is fairly heavy so if you're going for electric brakes it's good opportunity to drop some tongue weight and custom tailor it. Everyone seems to have a favorite and obviously the good old ball hitch is the path of least resistance. I usually prefer the 2" coupler on the tongue. That way you can put whatever the heck you want on there. In my case that's ball for highway, pintle off road and removed for theft deterrence.

I believe some non-pintle fans are using the ever popular combo pintle hook/trailer ball. I find those to be a poor fit with the rings and they bang around. Same thing applies with the small pintle and large lunette ring - the sloppy fit makes it noisy. Match the pintle to ring size and it's much more quiet and smooth.

@Verkstad @old_CWO

Thank you for the pointers. For now, my plan is to build the trailer in this order

1. Lower the trailer to level it with the tow rig

2. Build the box structure etc. and get it ready

3. Make multiple test runs and improve the structure as needed.

4. Swap out to Dexter axle, if needed, along with electric brakes but retain the lunette-pintle combo and remove the surge brakes

In all this, I intend to retain the lunette-pintle combo. I have read quite a few reports and watched videos about the pros and cons of the two majorly utilized articulating hitches - Max Coupler and Lock-n-roll. At this time, I feel that the old school lunette-pintle combo is much more simple and fool proof. The downsides of noise and rough rides can be worked around. This truck is not going rock climbing with the trailer anyways. It does not need a fancy articulating hitch. I am not a big fan of the ball hitch coupler.

Thank you for the pointers. For now, my plan is to build the trailer in this order

1. Lower the trailer to level it with the tow rig

2. Build the box structure etc. and get it ready

3. Make multiple test runs and improve the structure as needed.

4. Swap out to Dexter axle, if needed, along with electric brakes but retain the lunette-pintle combo and remove the surge brakes

In all this, I intend to retain the lunette-pintle combo. I have read quite a few reports and watched videos about the pros and cons of the two majorly utilized articulating hitches - Max Coupler and Lock-n-roll. At this time, I feel that the old school lunette-pintle combo is much more simple and fool proof. The downsides of noise and rough rides can be worked around. This truck is not going rock climbing with the trailer anyways. It does not need a fancy articulating hitch. I am not a big fan of the ball hitch coupler.

voodoo2crue

Member

I like your plan and I'm basically following the same plan. Level it out, build the box, and test. If a new axle is needed I can do that later, my theory is it cost me nothing to try it as is and find out if it will work. I'm also on board with keeping the pintle setup, it articulates well and is practically bullet proof. Mine is too noisy now because it's the pintle/ball setup but that will be switched out as soon as I get the new wheels on and see what else may be needed to level it out. Good luck with the build! I look forward to it!@Verkstad @old_CWO

Thank you for the pointers. For now, my plan is to build the trailer in this order

1. Lower the trailer to level it with the tow rig

2. Build the box structure etc. and get it ready

3. Make multiple test runs and improve the structure as needed.

4. Swap out to Dexter axle, if needed, along with electric brakes but retain the lunette-pintle combo and remove the surge brakes

In all this, I intend to retain the lunette-pintle combo. I have read quite a few reports and watched videos about the pros and cons of the two majorly utilized articulating hitches - Max Coupler and Lock-n-roll. At this time, I feel that the old school lunette-pintle combo is much more simple and fool proof. The downsides of noise and rough rides can be worked around. This truck is not going rock climbing with the trailer anyways. It does not need a fancy articulating hitch. I am not a big fan of the ball hitch coupler.

old_CWO

Well-known member

Step 1: Found the same set of wheels as my EX for the trailer today and bought them.

Are those going to fit without adapters? I thought modern Ford 8 lugs were metric pattern.

Are those going to fit without adapters? I thought modern Ford 8 lugs were metric pattern.

I will be using space adapters to convert from 8x6.5 to 8x170 bolt pattern. Though I’m not a big fan of spacers this will have to do until I have the time and money to do an axle swap.

voodoo2crue

Member

I was thinking about wheel adapters but ended up replacing the hubs, you may want to check out prices of hubs versus adapters. For me I ended up spending about $100 more but I now have new hubs/bearings and no spacers to worry about.I will be using space adapters to convert from 8x6.5 to 8x170 bolt pattern. Though I’m not a big fan of spacers this will have to do until I have the time and money to do an axle swap.

As it stands now, the trailer still sits quite a bit higher in the back essentially having a nose down kind of profile when hooked up with a 4" riser hitch. Has anybody switched the axles to go 'over' the leaf springs instead of under them as they come from the factory? I see that there are trusses on the outside of where the leaf spring is mounted which might block the plates when the u-bolts are flipped. Trying to avoid cutting/welding. I will have to replace the shocks to compensate the lower height.

old_CWO

Well-known member

Trailer looks good with the Ford wheels. I appreciate you posting the photos of the axle and springs, I have never seen an A3 up close before. It does appear a spring under would get it much closer to level with you truck.

Quick thought: could you notch the u-bolt plates to drop in between the trusses? Or maybe make a couple custom ones that would? If so, I would run a tap through the spring center bolt pocket in the top perch. That way you could bolt the plate to the axle so it can't shift around. Depending on your intended load you may consider removing the bottom two leafs from those packs while you're at it. That should lower it a little bit more and soften up the ride.

Quick thought: could you notch the u-bolt plates to drop in between the trusses? Or maybe make a couple custom ones that would? If so, I would run a tap through the spring center bolt pocket in the top perch. That way you could bolt the plate to the axle so it can't shift around. Depending on your intended load you may consider removing the bottom two leafs from those packs while you're at it. That should lower it a little bit more and soften up the ride.

Trailer looks good with the Ford wheels. I appreciate you posting the photos of the axle and springs, I have never seen an A3 up close before. It does appear a spring under would get it much closer to level with you truck.

Quick thought: could you notch the u-bolt plates to drop in between the trusses? Or maybe make a couple custom ones that would? If so, I would run a tap through the spring center bolt pocket in the top perch. That way you could bolt the plate to the axle so it can't shift around. Depending on your intended load you may consider removing the bottom two leafs from those packs while you're at it. That should lower it a little bit more and soften up the ride.

Thanks! I like to take pictures of the build process. Helpful to me, and others. Most importantly, I use it as a document to go back to at a later time if I am troubleshooting or wanting to redesign. More pictures are here.

I have not looked too deep into the current mounting and reasoning for that design. I will take your inputs into consideration when doing so. This will wait until I am able to get the cage, box structure, RTT etc. built and/or mounted on the trailer as that will determine how much the trailer is going to squat. Two of us sat on the trailer today, ~350 lbs between us and it flexed about 1-2".

vtsoundman

OverAnalyzer

I hate towing without trailer brakes....I don't care what the weight of the TV or the trailer. Much more control on road and the ability to manually activate the trailer brakes off road is key! You can do all sorta of things (getting to slide, pivot, etc) off road to help with positioning.

On road, if ya ever had to deal with some away from a semi or crosswind... being able to tap on the trailer brakes is a quick way to get it all under control again fast.

Surge brakes....are worthless. I hate em...would rather run without than deal with them (backing, bucking, or maintenance)...

Good to hear you're thinking about how to incorporate trailer brakes...

Sent from my Pixel 4a using Tapatalk

On road, if ya ever had to deal with some away from a semi or crosswind... being able to tap on the trailer brakes is a quick way to get it all under control again fast.

Surge brakes....are worthless. I hate em...would rather run without than deal with them (backing, bucking, or maintenance)...

Good to hear you're thinking about how to incorporate trailer brakes...

Sent from my Pixel 4a using Tapatalk

Slight change of plans for the tow rig.

After unsuccessfully trying to convince my wife that she could learn to comfortably drive the Excursion while on trips, I have decided to sell it. It will be replaced by a 2001 Lexus LX450 that I made a deal on this morning. This also means that some of the pans that I had for the M116A3 trailer will also be changing. I will need smaller wheels to match the LX, and this time, I am thinking of just prioritizing the axle swap to happen sooner so that I do not have to spend money on spacers once more. I will put the stuff that I bought a couple of weeks back on sale to fund the axle swap

After unsuccessfully trying to convince my wife that she could learn to comfortably drive the Excursion while on trips, I have decided to sell it. It will be replaced by a 2001 Lexus LX450 that I made a deal on this morning. This also means that some of the pans that I had for the M116A3 trailer will also be changing. I will need smaller wheels to match the LX, and this time, I am thinking of just prioritizing the axle swap to happen sooner so that I do not have to spend money on spacers once more. I will put the stuff that I bought a couple of weeks back on sale to fund the axle swap

Last edited:

JoshN

Observer

I would definitely swap the axle, and lose that surge break. You will literally shed hundreds of pounds. I would also suggest (and this is what I did) getting the AHC system removed and replace it with a conventional suspension for a Landcruiser with a 3-inch lift. Was I afraid it would fail on me? Nope. Toyota over-engineers everything. But I did not like that the AHC drops the truck at any speed over 25mph IIRC. I also did not like the mushy Cadillac-like ride it gave me. More though I didn't like the truck deciding to lower itself. With a trailer on the back that just makes for an awkward situation.

Similar threads

- Replies

- 1

- Views

- 612

- Replies

- 0

- Views

- 316

- Replies

- 2

- Views

- 1K

- Replies

- 8

- Views

- 1K