Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M2 Freightliner Ambulance Conversion Project. 2007 Crew Cab

- Thread starter Ozrockrat

- Start date

Coachgeo

Explorer

is that thing cast steel (cast iron)? don't you have to go thru ton of PITA complicated special steps to weld to it? Or is that bracket going to be a clamped onto the axle and or are you going to pick up existing mount holes to bolt this to the axle?

rlrenz

Explorer

Ok I need to tell someone about this. The missus is just not showing enough excitement.

Found a yoke (on eBay) that allows me to use the existing drive line (in 2wd) to get mobile in time for expo. Saving a lot of time and $$$.

Trying to match up to the mechanics 8.5c to my 1710 universal joints was proving impossible.

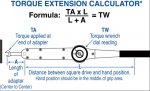

Getting the pinion nut torqued to 885 - 1030 ft lbs is going to be a bugger.

Look up the calculations for adding an extension to a torque wrench - By my 1:00 AM math, it calculates to be a 23" extension - or look for a torque multiplier. Northern Tool has then fairly reasonably. You could also use the torque multiplier they sell for truck lug nuts - with the 58:1 ratio, you'd need an input torque of about 16 ft-lbs, plus maybe 10% to account for gear train efficiency.

Have fun!

I am sure your welder knows what he is doing, maybe you could ask him what he is doing so you can post the procedure for others to use? That mount looks great, should be rugged as can be.

My fire truck project may not be doable, at least not like I wanted to, I would essentially need to cut the original frame off behind the cab and set it on top of an entirely new frame, this would give me enough clearance with the engine and transmission, but then it raises hell with my rear axle height. To top it off, I am trying to mount a knuckle boom behind the cab and they want the frame to be no higher than 42”, that isn’t going to happen with the larger tires.

My fire truck project may not be doable, at least not like I wanted to, I would essentially need to cut the original frame off behind the cab and set it on top of an entirely new frame, this would give me enough clearance with the engine and transmission, but then it raises hell with my rear axle height. To top it off, I am trying to mount a knuckle boom behind the cab and they want the frame to be no higher than 42”, that isn’t going to happen with the larger tires.

locrwln

Expedition Leader

Looking good. I would add some "fish plates" to the horizontal and vertical seam to avoid any future stress cracks forming. That vertical part is going to see a crap ton of side force.

Jack

Ozrockrat

Expedition Leader

Good idea Jack. I will plate them after the rest is welded. Here is the rest of the bits. 1/2” wrapped around the axle for lateral strength and the mounting plate for the panhard rod bracket. That will be drilled in place which will be a real bugger to do but easier to actually get right.

Last edited:

Ozrockrat

Expedition Leader

Go big or go home ! Looks great.

Actually I am past the point of easily returning it to its original (little) configuration so at the moment I think it’s “Go Big Or Stay Home”

1leglance

2007 Expedition Trophy Champion, Overland Certifie

I am going up Wed also ....will keep an eye out for ya during the Cool Ride CrawlWednesday sometime I hope. Hit the pub crawl thing that they have and onsite Thursday.

locrwln

Expedition Leader

Good idea Jack. I will plate them after the rest is welded. Here is the rest of the bits. 1/2” wrapped around the axle for lateral strength and the mounting plate for the panhard rod bracket. That will be drilled in place which will be a real bugger to do but easier to actually get right.

That's looking good. It's hard to "overbuild" an axle side track bar mount.

Jack

Similar threads

- Replies

- 1

- Views

- 824

- Replies

- 1

- Views

- 682

- Replies

- 2

- Views

- 2K

- Replies

- 0

- Views

- 1K