So, pulled it apart again and started assembling in earnest. I'd decided that instead of copious mastic I would seal the sections together at the rear corners and the long seal on the side of the roof with 2mm self-adhesive neoprene strip, then it would be easy to dismantle should I have to. Then simply put a thin smear of sealant down the joint onto the neoprene.

And thats what I did, lots of bolts, and cursing, as the usual gremlins made their presence felt, but it all went together. Once that was done it was attach lower seals so that when the roof is lowered there's something to stop water blowing in and making the sides damp - water cant actually get into the vehicle because the original gasket sealing the roof is still in place, so its really only to keep the inner surface of the lifting sides dry. So now, hopefully, it is fully sealed.

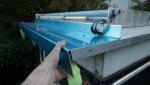

Alloy Keder strip rail that the awngin attaches to but which doubles as a gutter to stop ingress of water to the back door seals beneath it.

I took it out yesterday for a maiden voyage and got up to 60mph with no creaks, grumbles or rattles and nothing fell off. I could feel the wee bit extra weight but its not drastic, a few extra pounds pressure in the rear airbags will fix that.

I'm now inside fitting the seals along the sides and back which is a bit of a faff and I'm not entirely certain how I'll do that but I have a few ideas, but good thing is I can do it inside the van in the dry so hopefully not too terrible a job - not like the winter work standing outisde with the arctic blasts rattling my underpants.

Also - the way to access the back is to swing away the wheel, lift the whuffling gas strutted exterior door, then open the original LR back door. And the added bonus is that when the roof is lifted the top hung exterior door on the lifting section allows the whole end of the lifting roof to open for fresh air and views!

I was really pleased that the wide open upper door appears to have worked! It was a solution to the lifting 'shell' interfering with the original LR back door opening, and once I gave it some consideration I thought 'well might as well see if I can get it to work in the roof-up position'. Getting the angles right so the original LR back door doesn't hit it was interesting. I'm now trying to get seals figured out so the bottom of the external lifting door seals when its lifted but also seals agasint the old door when lowered. More of that another time.

Weight of the total thing is about the same or slightly less than a roof rack and roof tent. A typical large roof tent is 80kg and a decent 110 roof rack around 50 or 60kg. so around 140kg. The sides and rear I've just built are 60kg and the roof 70kg so 130kg total. Crucial things is a good chunk of this weight is carried down low. Its also made the interior a lot quieter when driving.