mogwildRW1

Adventurer

The real question is, did you make multiples of everything, because those are some nice, worthwile upgrades that I'd want if I ever bought an SBU again

The real question is, did you make multiples of everything, because those are some nice, worthwile upgrades that I'd want if I ever bought an SBU again

Round cab, which I enjoy very much, but there's always a chance I might acquire another square cab, and headlights were one major issue on the square cabs that needed addressed (easy to out-drive your lights with the stock headlights). Miss my old RW1 but I'm living vicariously through your buildI could never bring myself to remove the rear fire box (as much as I wanted a regular box) so it's nice to see once properly done. Keep up the good work.

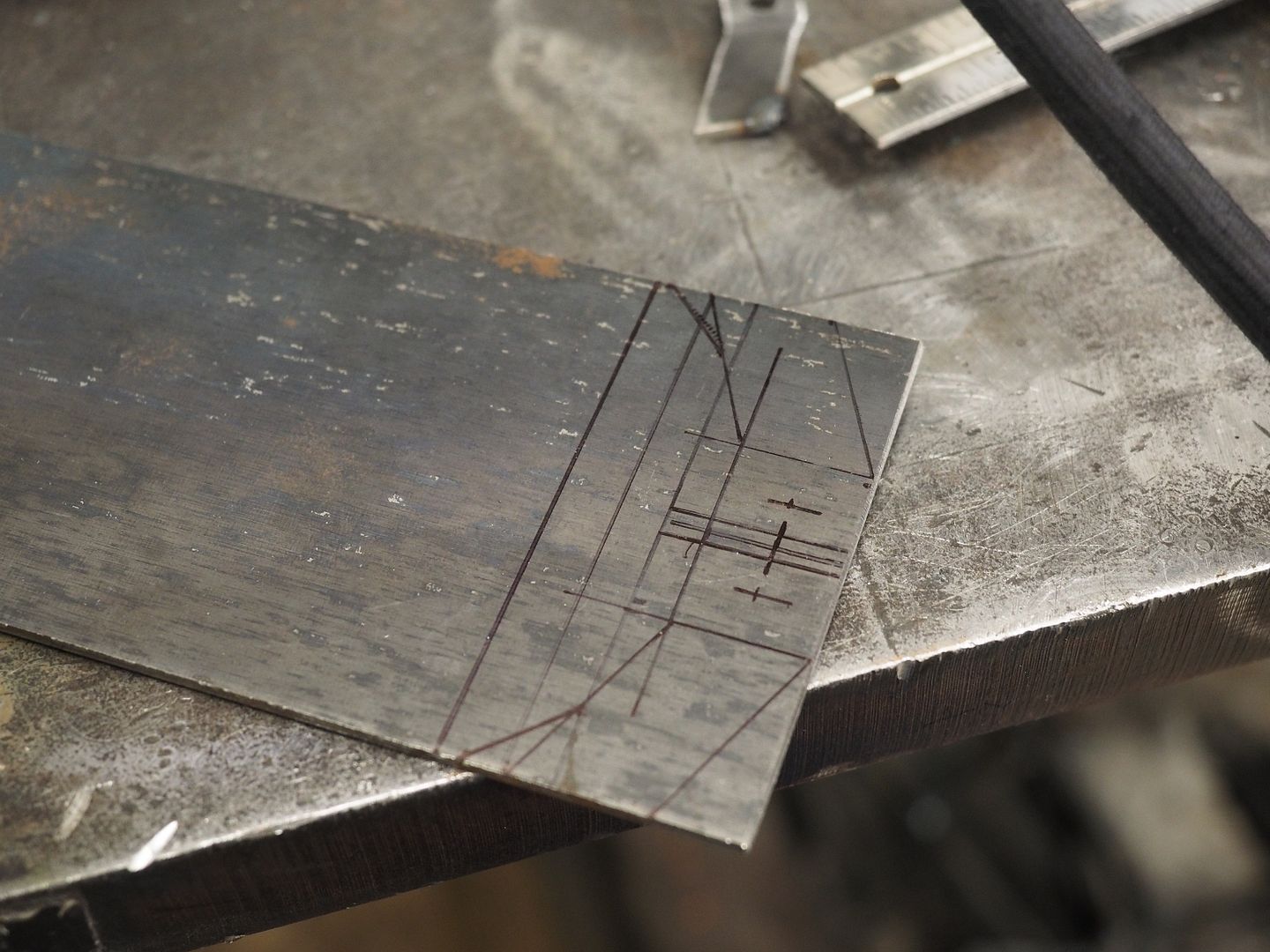

Great fabrication work

Respect - again! Nice job. Your work makes we need a MOG