Some vehicles have very compliant suspensions, some have very compliant frames, some have a combination of both. Problems ensue when superstructure designs give different flexibility than was originally designed into the vehicle frame - a classic example is someone running a Unimog derived superstructure on a frame that's not designed to flex as much as a Unimog.

For example, a smaller FUSO with a frame that's designed to be somewhat limited in flex. The thing is that the limiting factor, to a great extent,

is the superstructure. It adds stiffness and lets the frame last longer under load. Remove that stiffness, put the frame under full load and run it over terrain that maximizes torsional stress and the frame eventually breaks faster than if it was limited. All the trucks I've seen have integrated their approved superstructure designs into the frame calculations, none have been designed to run only as a cab and chassis.

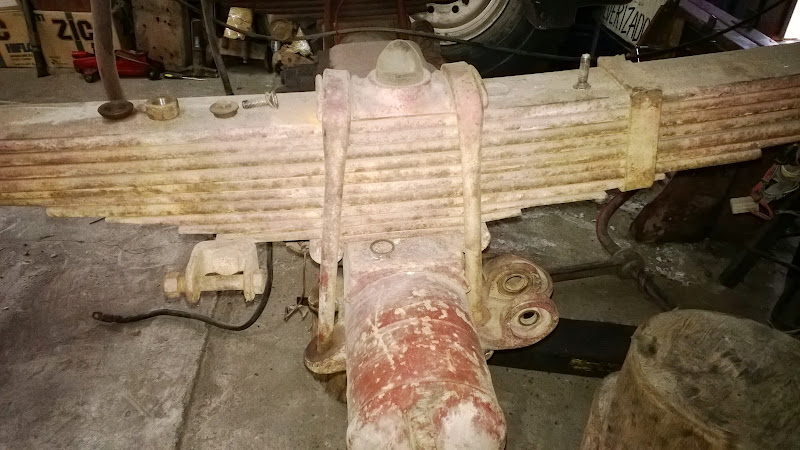

I think your truck is short enough, stiff and rigid enough that you won't have any issues with any coach of reasonable size. As long as it's in good shape to begin with, which might be something to consider. Lots of these trucks have had a tough life prior to our grabbing them. Some already have rust, rivet issues, distorted frame members, etc.

The good thing about running a truck that's the size of the one you have is that it's extremely heavy duty for your application. The bad thing is that it's extremely heavy duty

.

Everything's a compromise, the torsion free box concept is also a compromise.