So I'm another in the list of folks who watched perkj's initial postings and thought "I'd like to do something like that." I dwelled on it all for a long time but bit the bullet recently when I realized we wanted to have partial shelf setup with room on the other side for our primary cooking gear and such. In particular, I wanted to have the ability to strap down my tool setup, some recovery gear, and eventually mount a powertank and rotopax while also having the ability to quickly slide our camp chairs and tables in/out without having the restrain them. At least that was my logic.

So in my typical way, I turned to graph paper and did a sketch to scale.

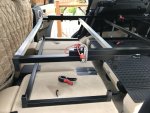

Using the measurements and a sketch of the aluminum frame, I ordered the parts from EZtube. I went with the plastic connectors and just cut the lengths of tube myself. To mount the shelf I decided to use cross pieces under the frame that would bolt into the L-track I have fitted via

double lug threaded studs. Continuing with that theme, I grabbed some more L-track for the shelf itself which I decided to use black starboard for because I wanted something durable that wasn't painted metal, wood, nor carpeted. Initial confirmation that the graph paper mockup of key bits was correct.

Then making sure the top would work out in some form/fashion.

Installed L-track on the top to allow for lashing down items with flexibility.

Frame elements put together before painting to confirm fit.

Testing out that our two camping tables and two camp chairs will fit into the space allotted.

Then validated that our pelican case holding the volcano along with our two wolfpacks (K1 & K2) would all fit into the right side of the cargo area too.

Paint has now cured, its all bolted together and in the truck for some test runs to check for rattles and functionality. Next step will be improving on the lashing system, installing a powertank and rotopax at the far aft end, etc.

All told, as others have noted, a solid find by Perkj with a lot of inherent flexibility for the end user to make what they need in a lightweight but durable form. I'm very happy with the overall product and look forward to shaking the truck down with it this fall/next spring.

r-

Ray