She needed a lift, so I went for a 3" Dobinsons lift kit with JBA UCAs, came out pretty nice. Little firmer ride, got rid of some of the nose dive while braking but retained most of the ride quality.

[url=https://flic.kr/p/2jdQKEB]

Started by seeing if the camper would fit 33's...it does. The tires on it are starting to dry rot, I bought them dirt cheap second hand, so it's time to replace them and I'm a fan of carrying less spare tires and thus all tires (rig and trailer) matching. I've had to talk myself out of spending $450 just to have wheels that match the rig...that's stupid, right...right? The ProComp black wheels should be just fine, though they do take a different wheel lug key than the rig and I would like to only carry one...no, no that's silly. I'll just match the tire sizes.

[url=https://flic.kr/p/2jdKKxd]

I've begun tackling the interior and some other maintenance items on the camper. We spent all last summer and winter on house projects and I'm ready to finish up some things and get back out there this summer.

First thing on the list was replacing the roof vent. I originally didn't splurge on a big name vent fan setup and I've kinda regretted it since. The dirt cheap option I went for was ok, but has taken a beating off road and needed replaced. I used the opportunity to upgrade to a Fan-Tastic Vent 1250 series (has reversible fan direction).

Let me say, cleaning off the old EternaBond vent sealer was a mess and a chore. The stuff works great, but that also makes it a mini-nightmare to remove.

I attacked it with a few different approaches and ultimately, using a razor blade and "skinning" it, like one would process an animal, was the fastest approach and left behind just as much sticky goo as all other methods.

Done with the mess and new vent brim sealant on. Then new vent in place and new ExternaBond for a weatherproof seal.

Next I tackled a little annoyance we had while using the camper; the doors swinging shut when you wanted them to remain open. Easy fix was some spring loaded door catches. The corners of the catch arm were a little too sharp considering they catch on the weather seal of the door, so I added some shrink wrap to the 1/2 inch catch arm section and will just try to be careful to not rip the doors weather seal.

Next item was to address the ceiling and figure it out so we can move on to building out the galley area. We've been rocking it with just exposed insulation, which has been fine. Here's how it looks, as a reminder. You can peek our green tape galley designing.

I contemplated many different approaches on how to achieve a ceiling covering, many different materials and methods, ultimately deciding on using a vehicle headliner material and adhering it with 3M spray adhesive. It helped me avoid any screws into metal framing (causing a heat sink and thus sometimes dripping moisture from the ceiling) and was light weight and forgiving, but not perfect. The ceiling isn't smooth, plenty of ripples, uneven joints etc but we can get over the cosmetic imperfections and enjoy the ease and function.

Pretty straight forward. Ordered a roll of black headliner, with padding, off Amazon (about $50 for a 5' by 9' section). I used some wiring hiding tube stuff, it's like a half circle tube with double sided tape on one side, to help route the vent fan wiring to behind the galley wall, which is where I'll be placing a little junction box for all the cabin wiring (battery and such will be in the galley, just need an actual junction point a little closer to the switches we'll be installing).

Here's the final product.

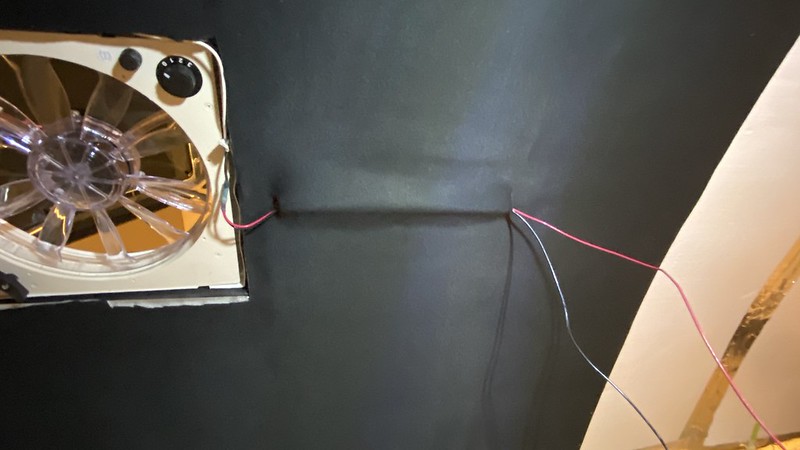

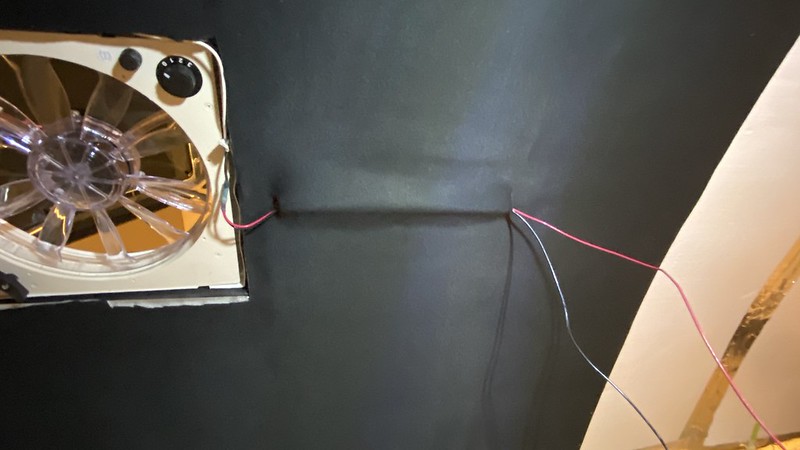

The wiring tube installed between the ceiling and headliner:

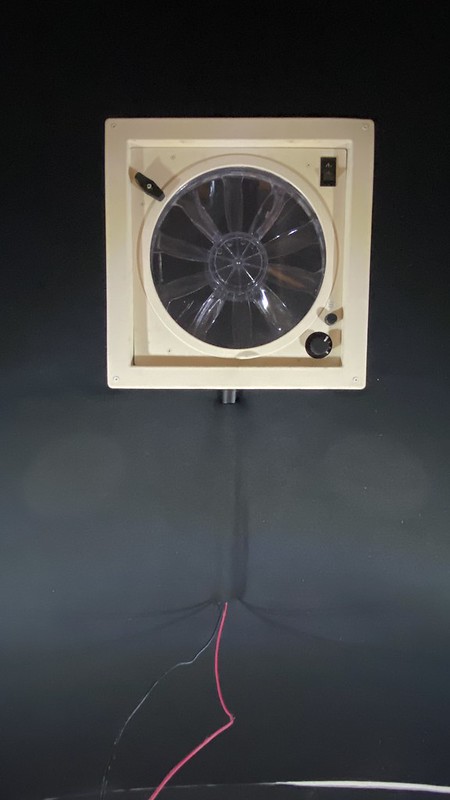

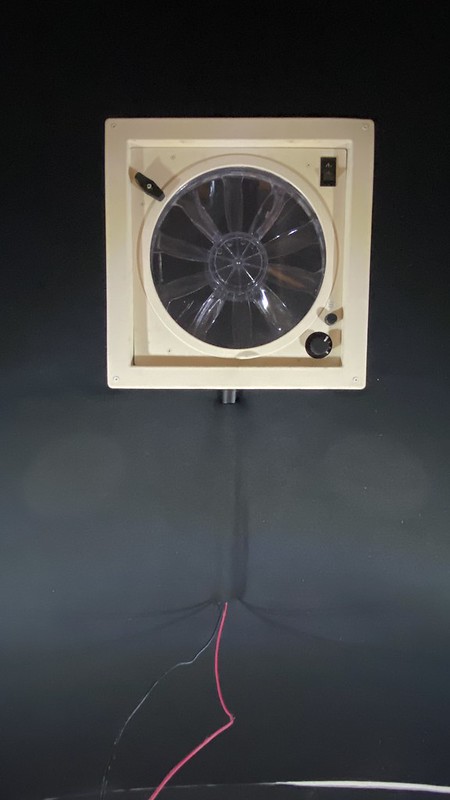

How it turned out with the vent surround installed

The headliner option isn't perfect by any means, but I'm still happy we went this route. I'll get some 1/2 or 1/4 inch 45 degree trim edge fillers and line the space between the top of the side walls and where the headliner stops for a nice finished look and to stop the headliner from pealing up from the edge.

The front section, at the head of the trailer, is all kinds of curves and was never going to be perfect. It turned out with a lot less wrinkles and bulges then I imagined though. Not too concerned with perfection on the headliner, as it'll serve as an improved cosmetic form as well as a nice improvement to the acoustics inside the trailer.

The last thing I tackled today was the area that's going top be between the "headboard" and the ceiling. I used some white plastic shiny flexible board stuff, the kind that's used in more industrial kitchens on walls and such. It's cheap, flexible, sturdy enough and easy to clean. Hard to see in the photo, but it has a finishing trim on the top to create a clean line at the headliner transition and I kept all but 4 bolts below the line which will be seen when the headboard is built.

That's it for today, off to play some tomorrow.

Cheers!